Thick steel plate

A thick steel plate and quality technology, applied in the field of thick steel plate, can solve the problem of HAZ toughness deterioration and achieve the effect of excellent HAZ toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] The present invention will be described more specifically by way of examples.

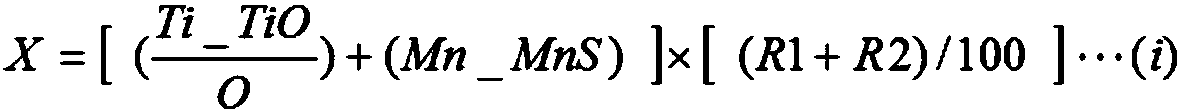

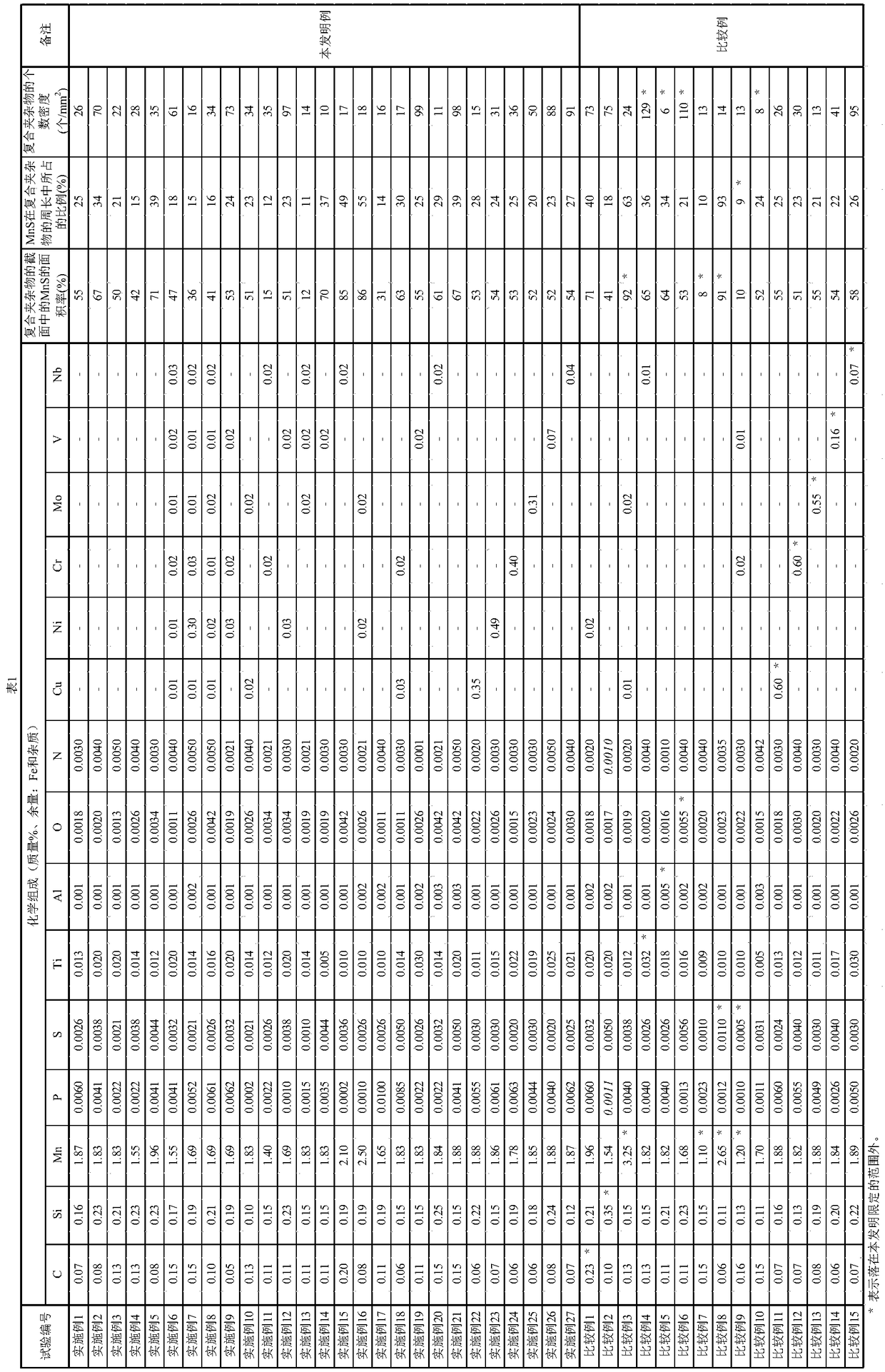

[0124]

[0125] Steels having the chemical compositions of test numbers Examples 1 to 28 and Comparative Examples 1 to 18 shown in Table 1 were melted through the actual manufacturing process. In this manufacturing process, the total amount of Fe in the slag is adjusted by blowing Ar gas from the top into the molten steel before the RH vacuum degassing treatment to cause the slag on the surface of the molten steel to react with the molten steel.

[0126] The flow rate of Ar gas was adjusted within the range of 100 to 200 L / min, and the blowing time was adjusted within the range of 5 to 15 minutes.

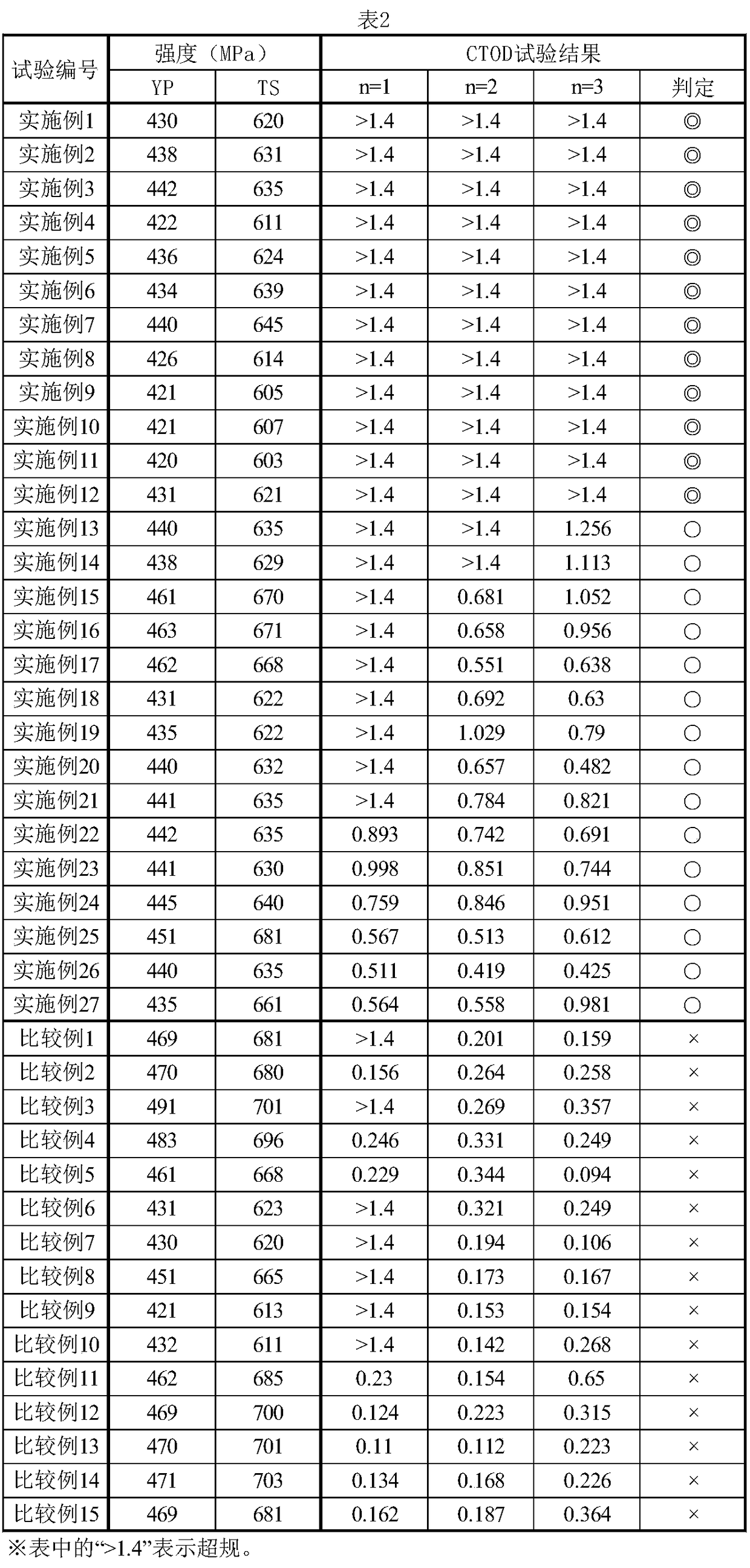

[0127] Afterwards, each element was added by the RH vacuum degasser to adjust the composition, and a 300mm slab was cast by continuous casting. The cast slab is heated in a heating furnace in the range of 1000-1100°C. After heating, it is hot-rolled at a temperature of 760°C or higher until i...

Embodiment 9

[0147] In Example 9, although the CTOD test result was acceptable, the YP and TS were low because the C content was close to the lower limit of the range of the present invention.

Embodiment 10

[0148] In Example 10, although the result of the CTOD test was acceptable, the YP and TS were low because the Si content was close to the lower limit of the range of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com