Centrifugal compressor

A technology of centrifugal compressors and impellers, applied in mechanical equipment, engine manufacturing, machines/engines, etc., can solve problems such as pressure loss, achieve the effect of reducing peeling and improving compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

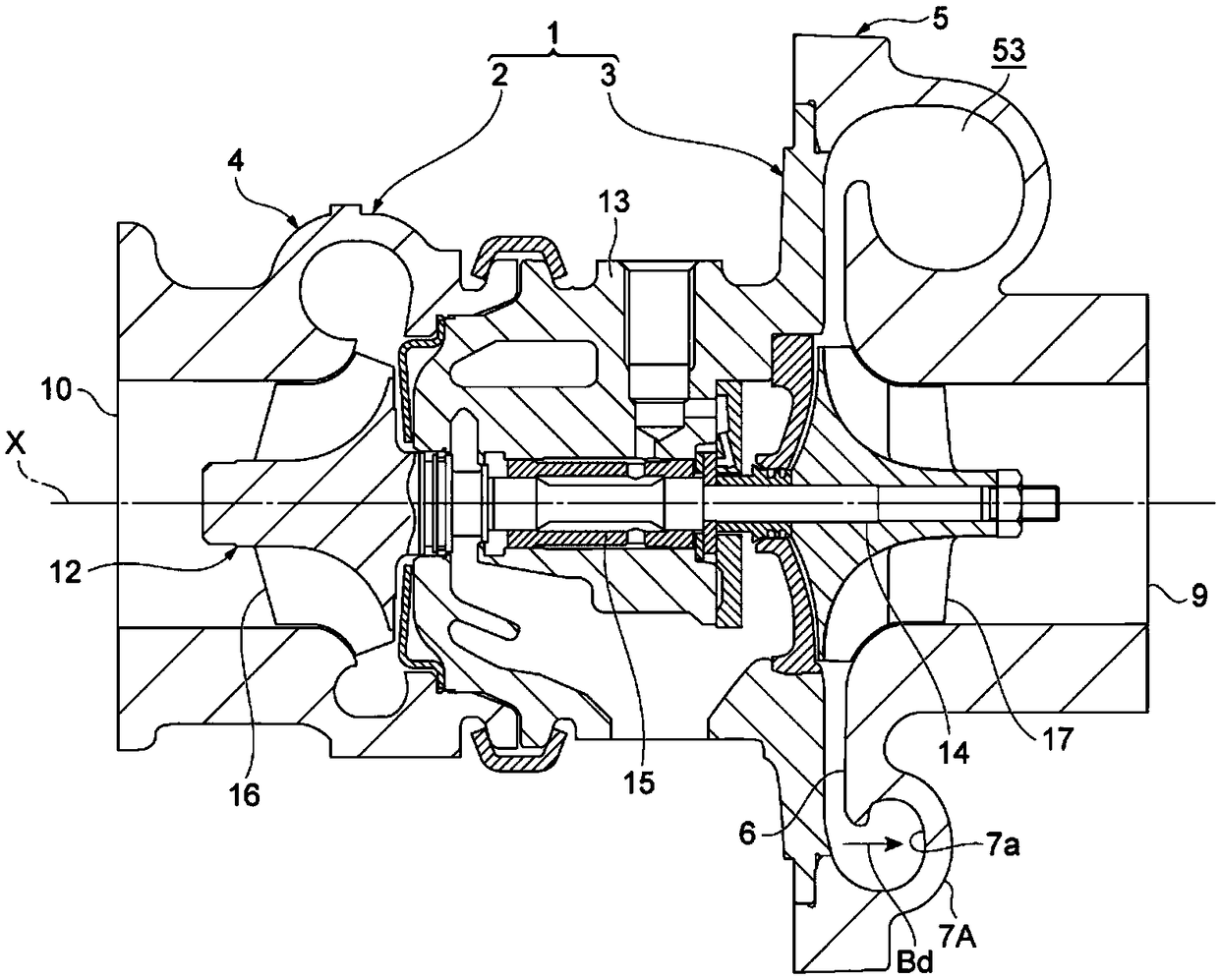

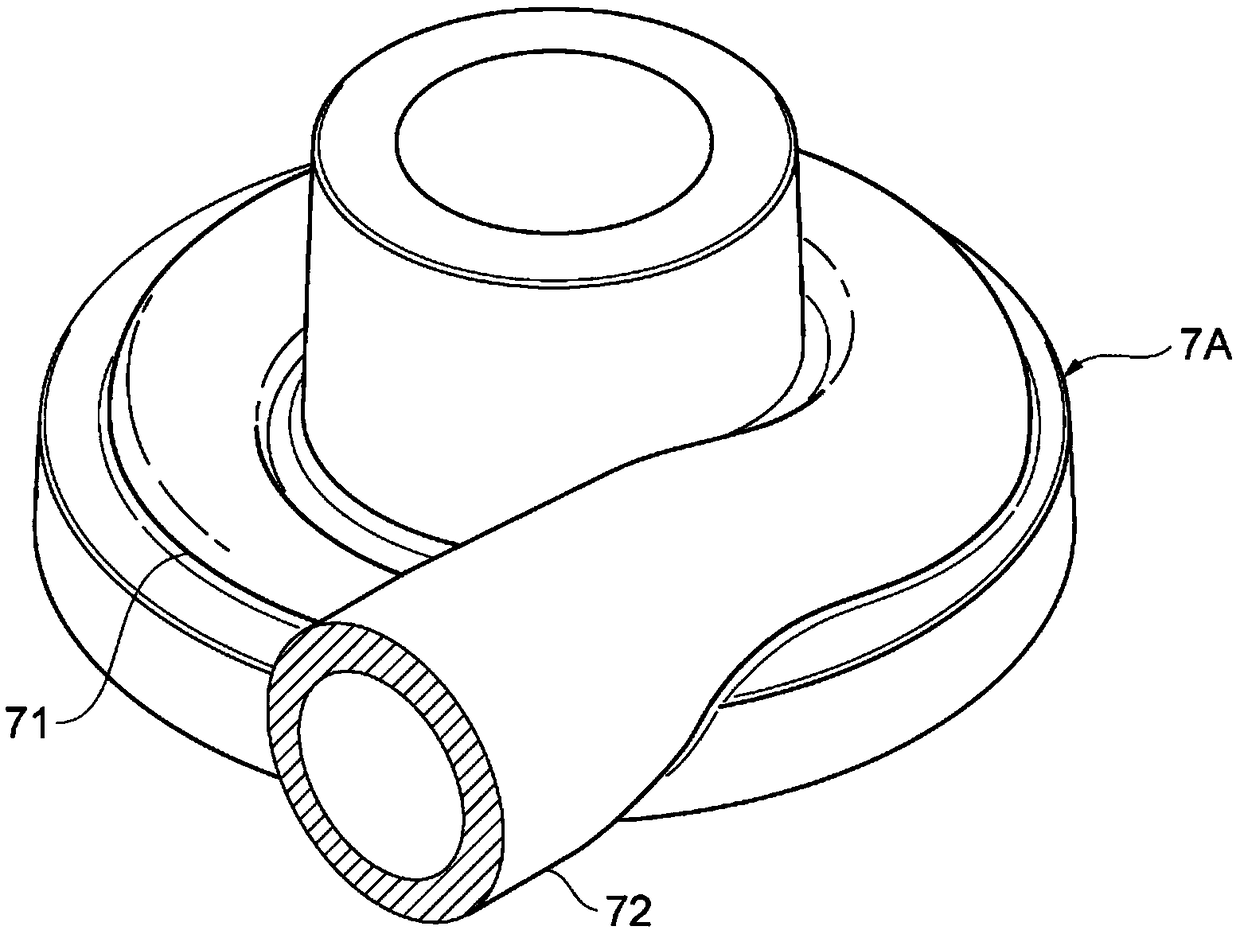

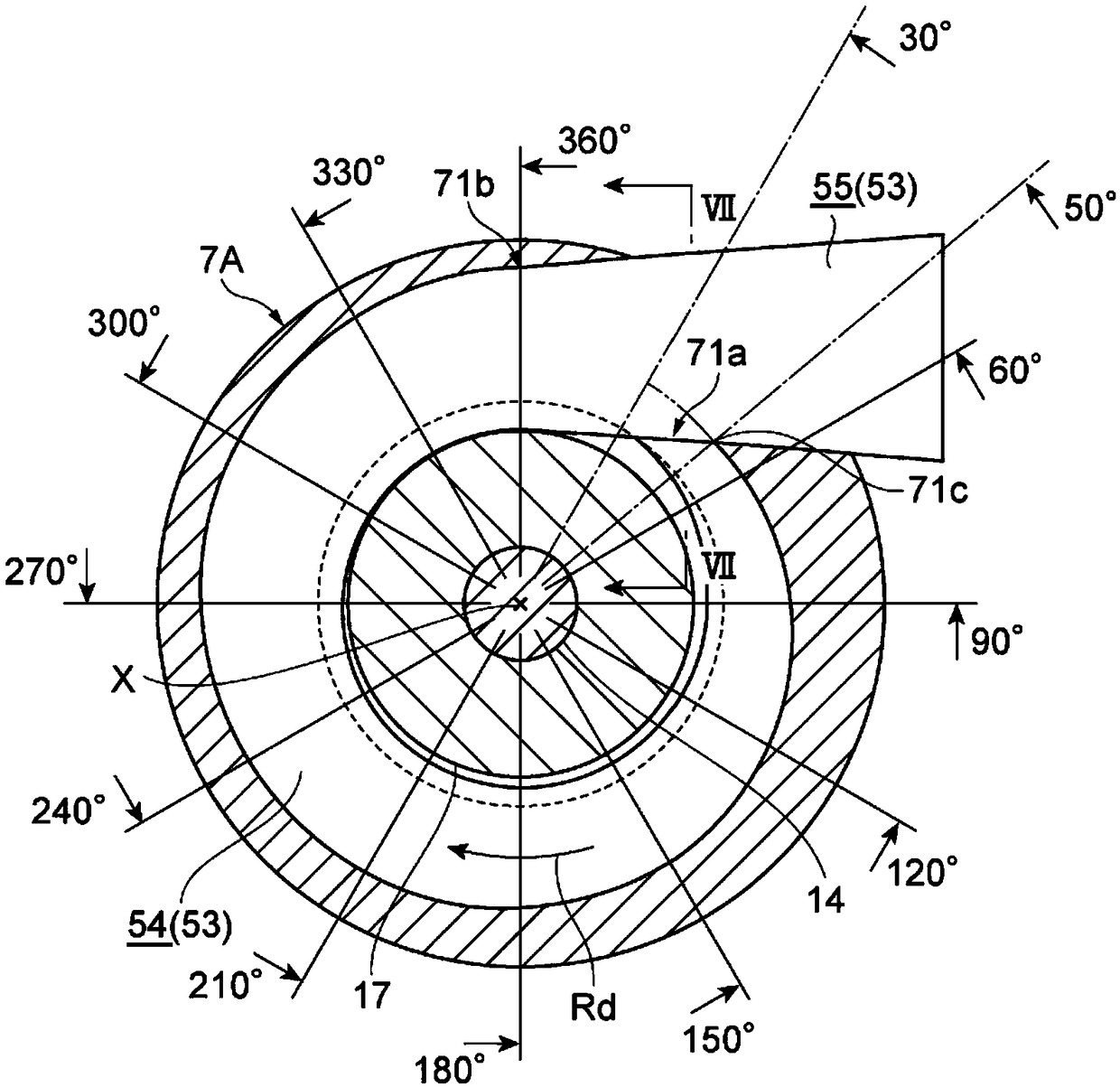

[0022] A centrifugal compressor according to one embodiment of the present invention includes: an impeller, and a scroll arranged around the impeller and forming a flow path including a scroll flow path along the rotation direction of the impeller, and the scroll includes: The discharge part connected to the winding end part of the scroll flow path, and the winding start part connected to the discharge part, the winding start part is connected at an obtuse angle with respect to the discharge part on the suction side in the direction along the rotation axis of the impeller. .

[0023] In the centrifugal compressor of this embodiment, the winding start portion is connected at an obtuse angle to the discharge portion on the suction side in the direction along the rotation axis of the impeller. Therefore, the fluid flowing into the winding start portion from the discharge portion is less likely to be separated, which contributes to the improvement of the compression performance. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap