Multi-cavity tubes for air-over evaporative heat exchanger

A heat exchanger, evaporative technology, applied in the field of evaporative air heat exchanger, to achieve the effect of reducing the effective diameter, solving the increase of weight and cost, and improving the heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

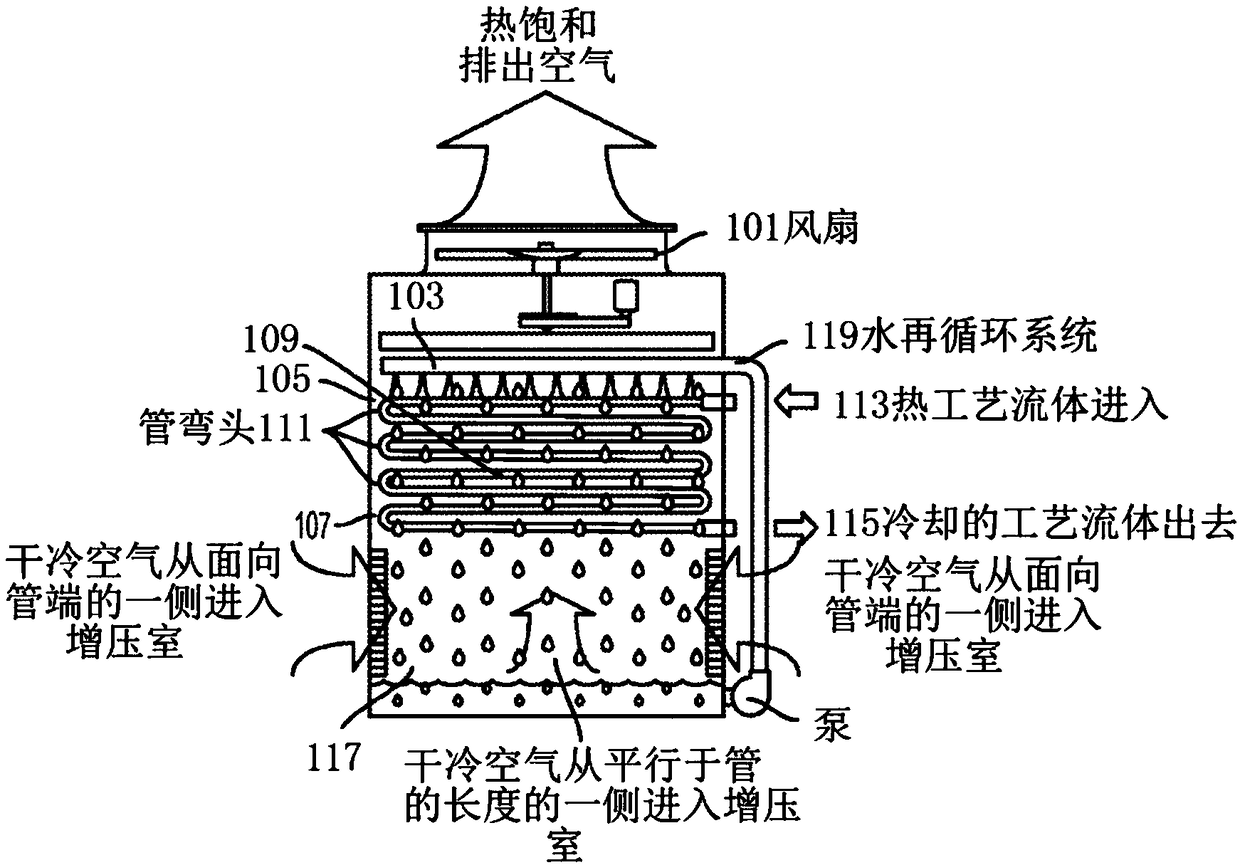

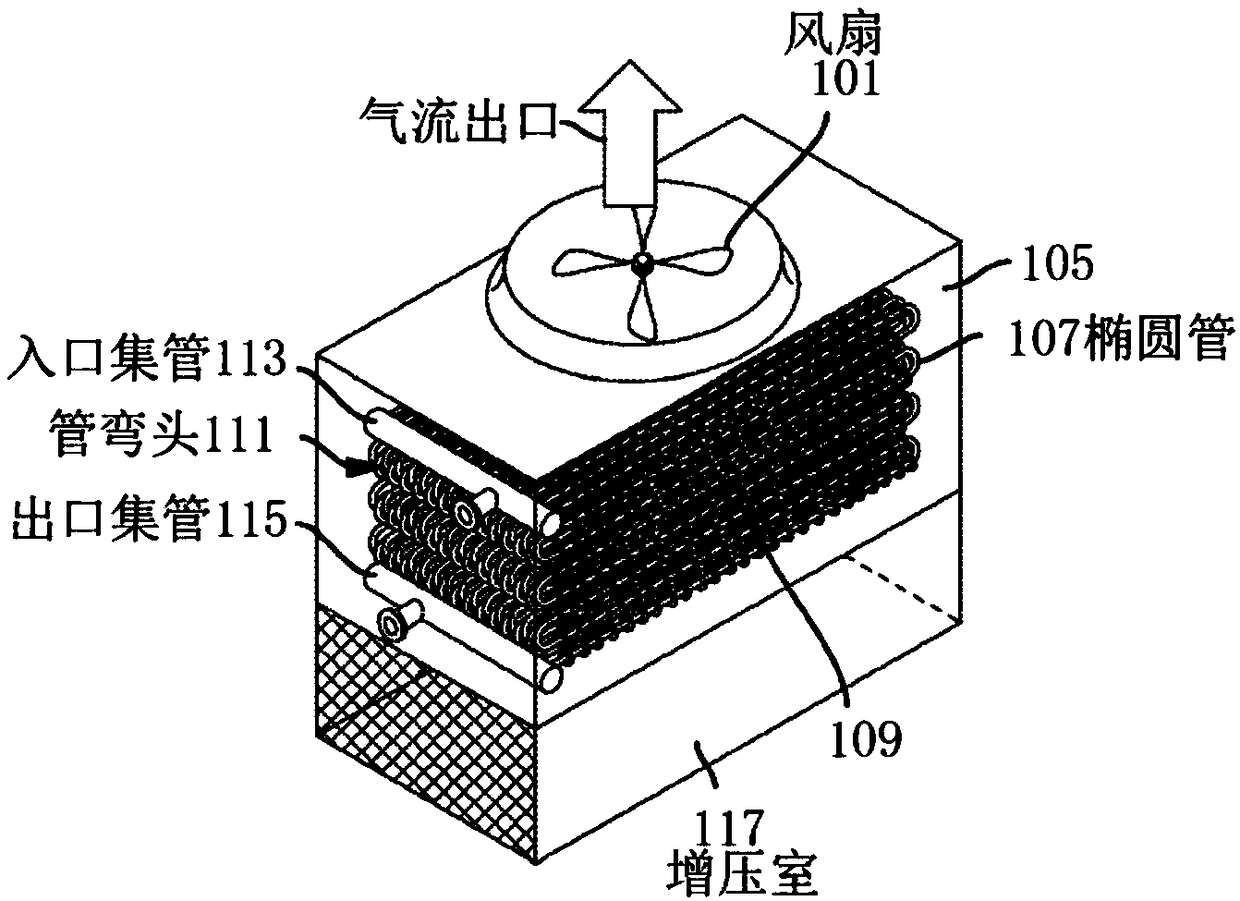

[0035] figure 1 and 2 An induced draft single cell evaporative cooler according to the prior art is shown. The fan 101 draws air into the device and forces it out the top of the device. Below the fan is the water distribution system 103 which distributes water over the coil 105 . The coil consists of a row of serpentine oval tubes 107 . Each length of tube 109 is connected at its end to an adjacent higher and / or lower length of tube by a tube bend 111 . Process fluid to be cooled enters the tubes through inlet header 113 and leaves the tubes through outlet header 115 . Below the coil is a plenum 117 where air enters the unit and water delivered to the unit by the water distribution system 103 is cooled by direct heat exchange with the air, water is collected at the bottom and recirculated to the top by a water recirculation system 119 .

[0036] image 3 and 4 show figure 1 and 2 A conventional evaporative heat exchanger oval tube 107 used in prior art heat exchangers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com