Busbar current sensor assembly

A technology of sensor components and current sensors, which is applied in the direction of electrical components, current only, voltage/current isolation, etc., and can solve problems such as reducing the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

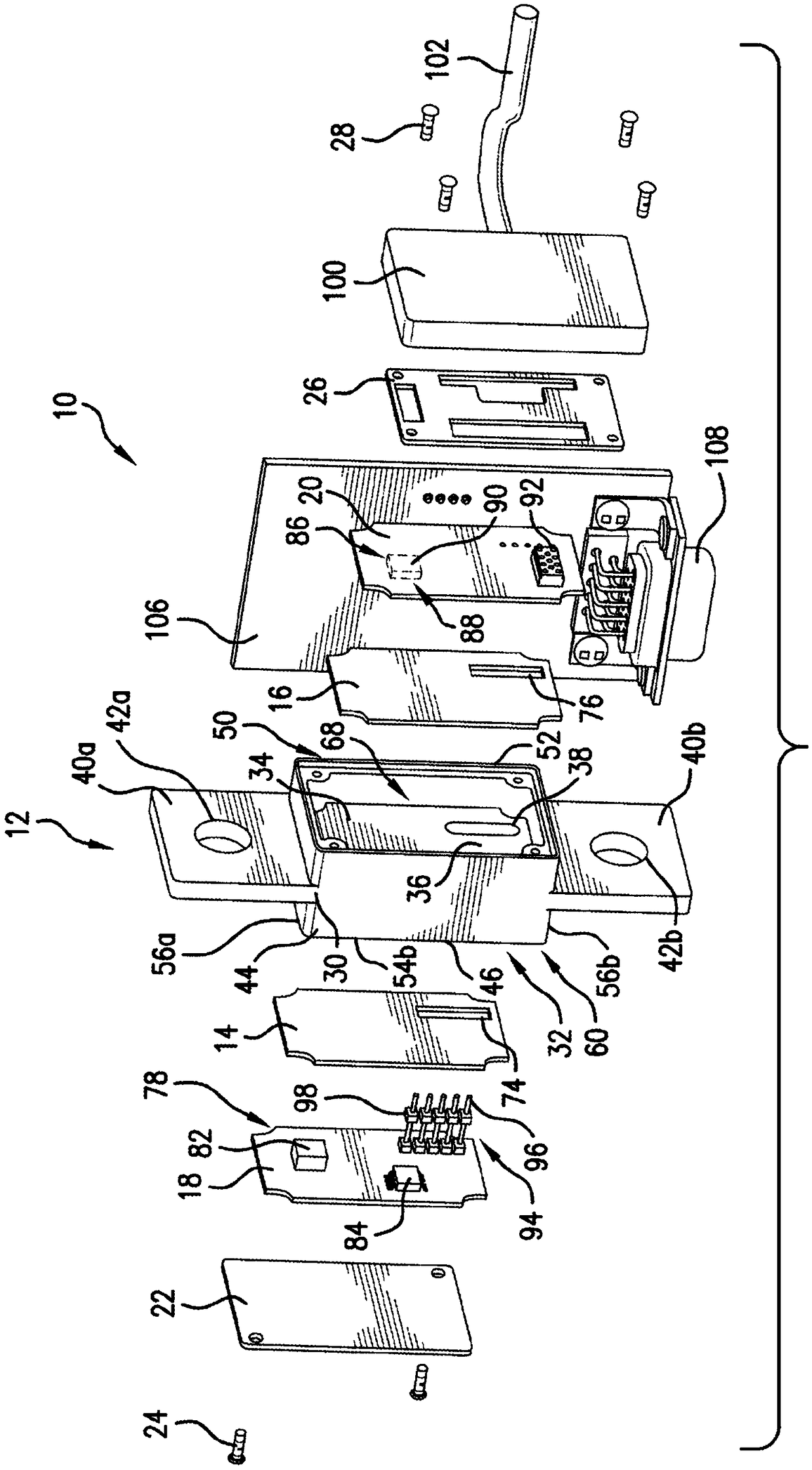

[0010] figure 1 Components of bus current sensor assembly 10 are depicted. The bus bar current sensor assembly 10 may include a bus bar member 12, a first insulator 14, a second insulator 16, a first circuit board 18, a second circuit board 20, a first cover 22, a first fastener 24, a second cover 26 and Second fastener 28 .

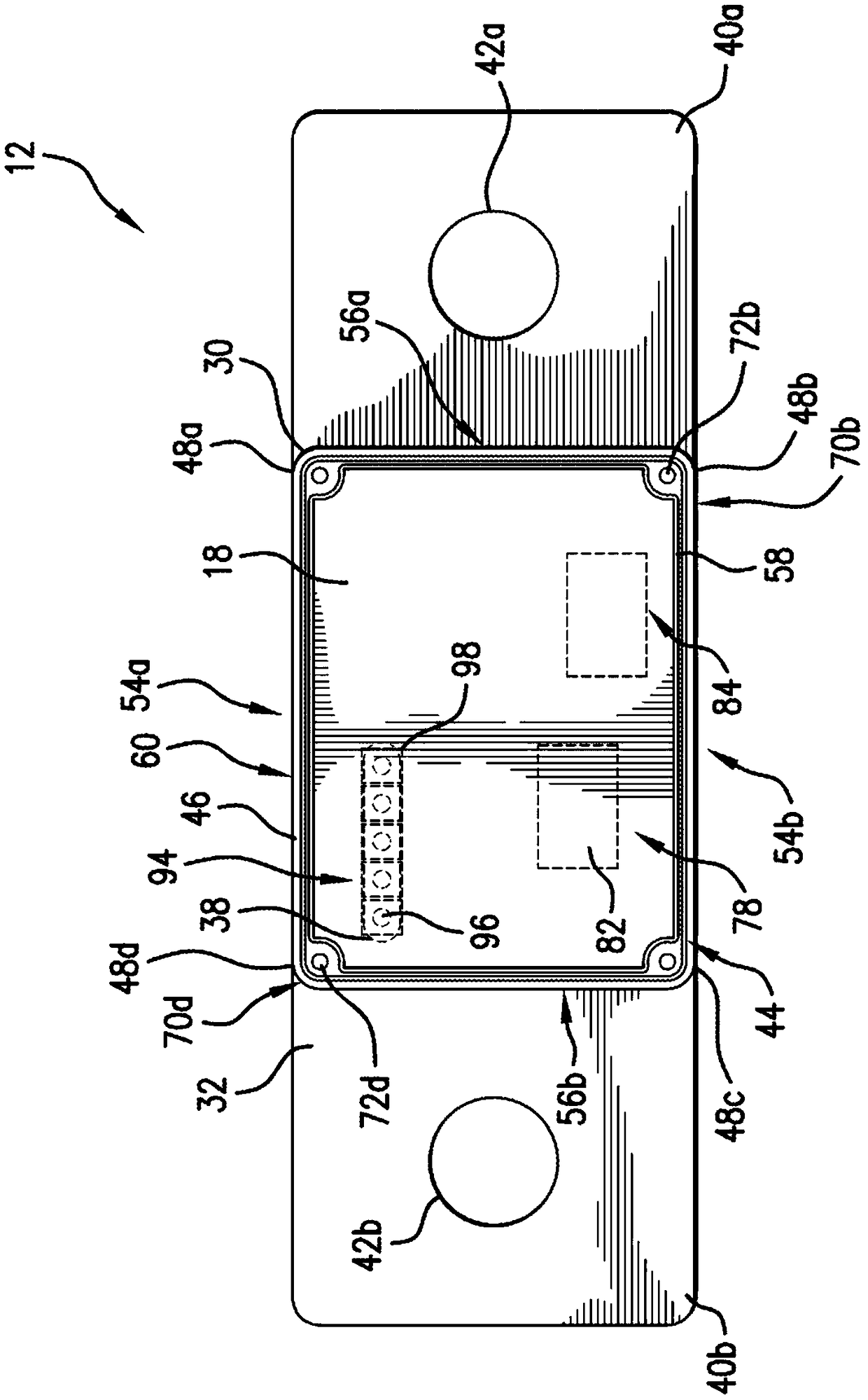

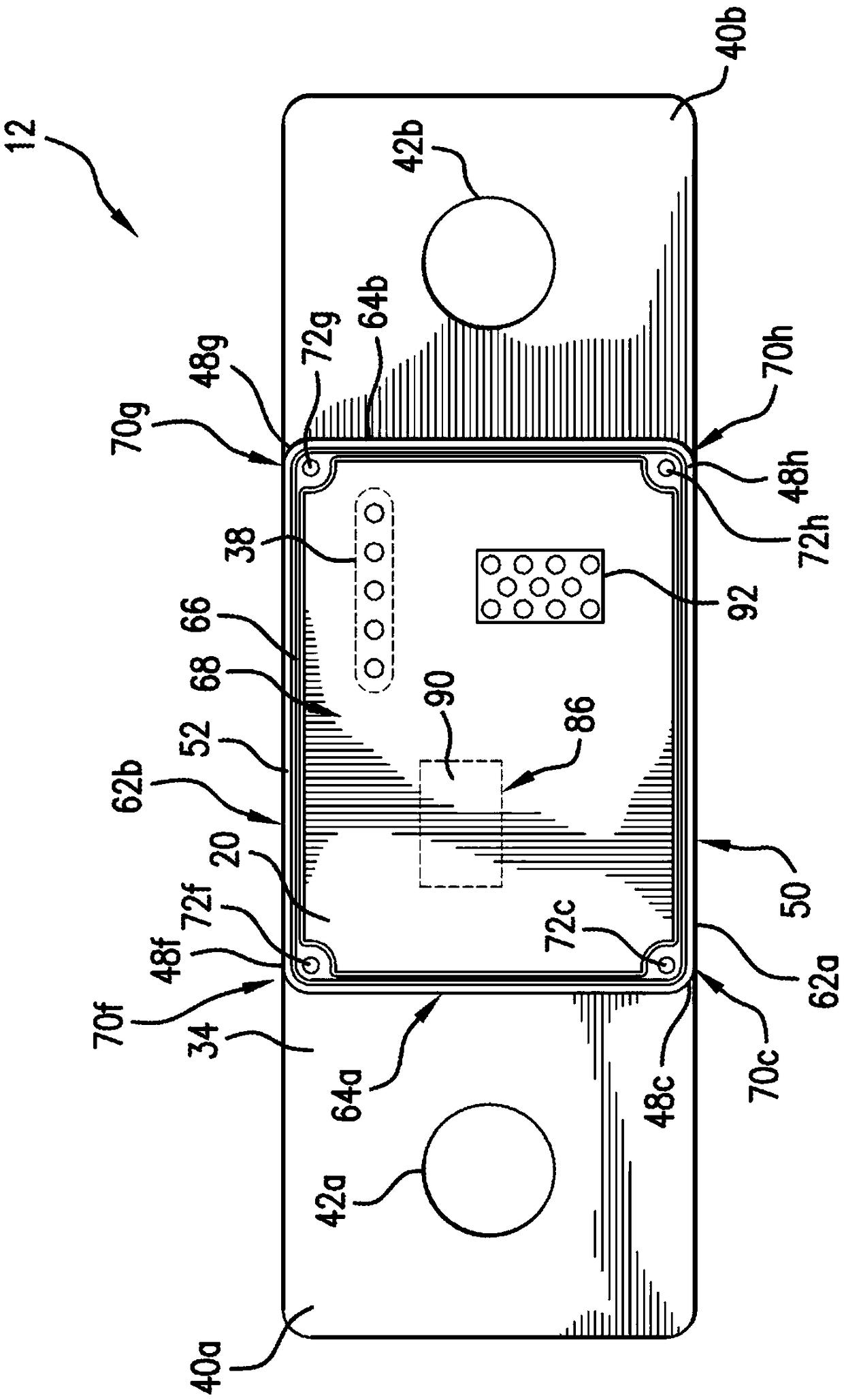

[0011] refer to Figure 1-3 , the bus bar member 12 is made of conductive material, such as copper or aluminum. Also, the busbar member 12 may be coated with any number of substances including, for example, nickel. The busbar member 12 includes a base 30 having a first surface 32 facing in a first direction and a second surface 34 facing in a second direction. The first direction is opposite to the second direction. A cross-section of the busbar member 12 can be manipulated to adjust the magnetic field strength in the vicinity of the magnetic field sensing components. It will be appreciated, however, that there are practical limitations to adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com