Double-row fixed-quantity spiral fertilizer feeder

A fertilizer discharger and spiral technology, which is applied in the field of a double-row quantitative spiral fertilizer discharger, can solve the problems of inability to meet the fertilizer requirements of different crops, inconvenient adjustment of fertilizer discharge volume, inconsistent fertilizer discharge volume, etc., and achieve improved fertilizer discharge. Efficiency, improvement of fertilizer utilization rate, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

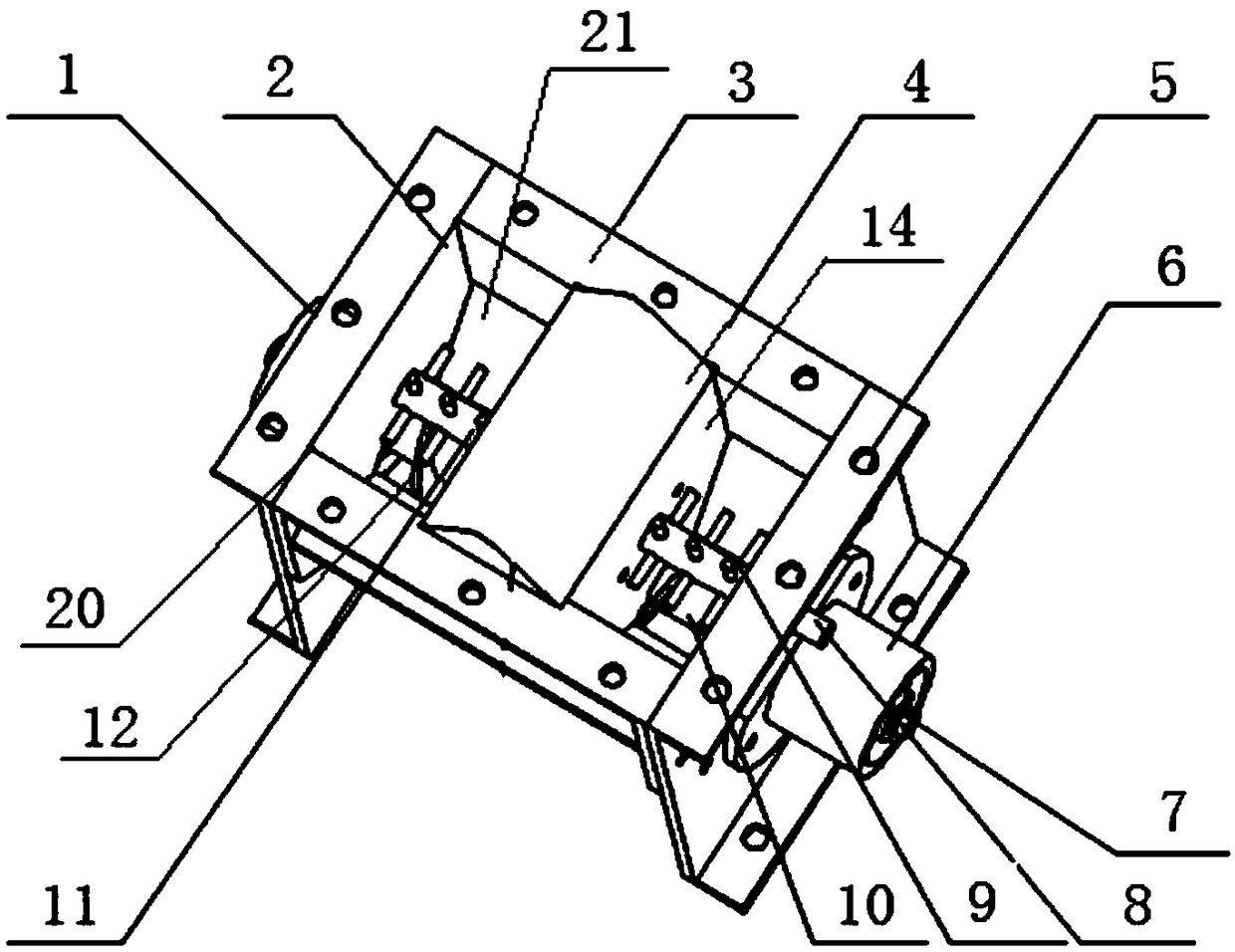

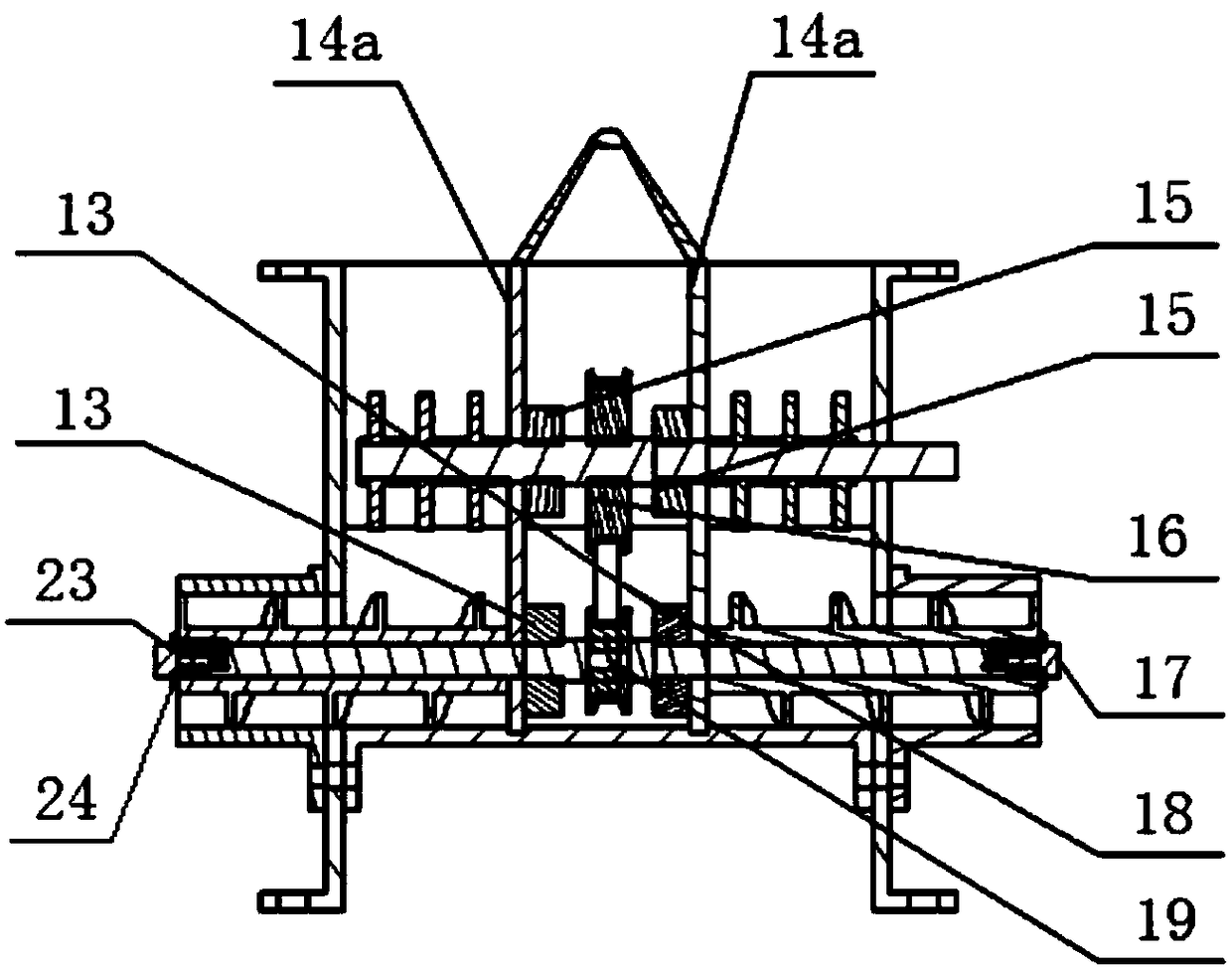

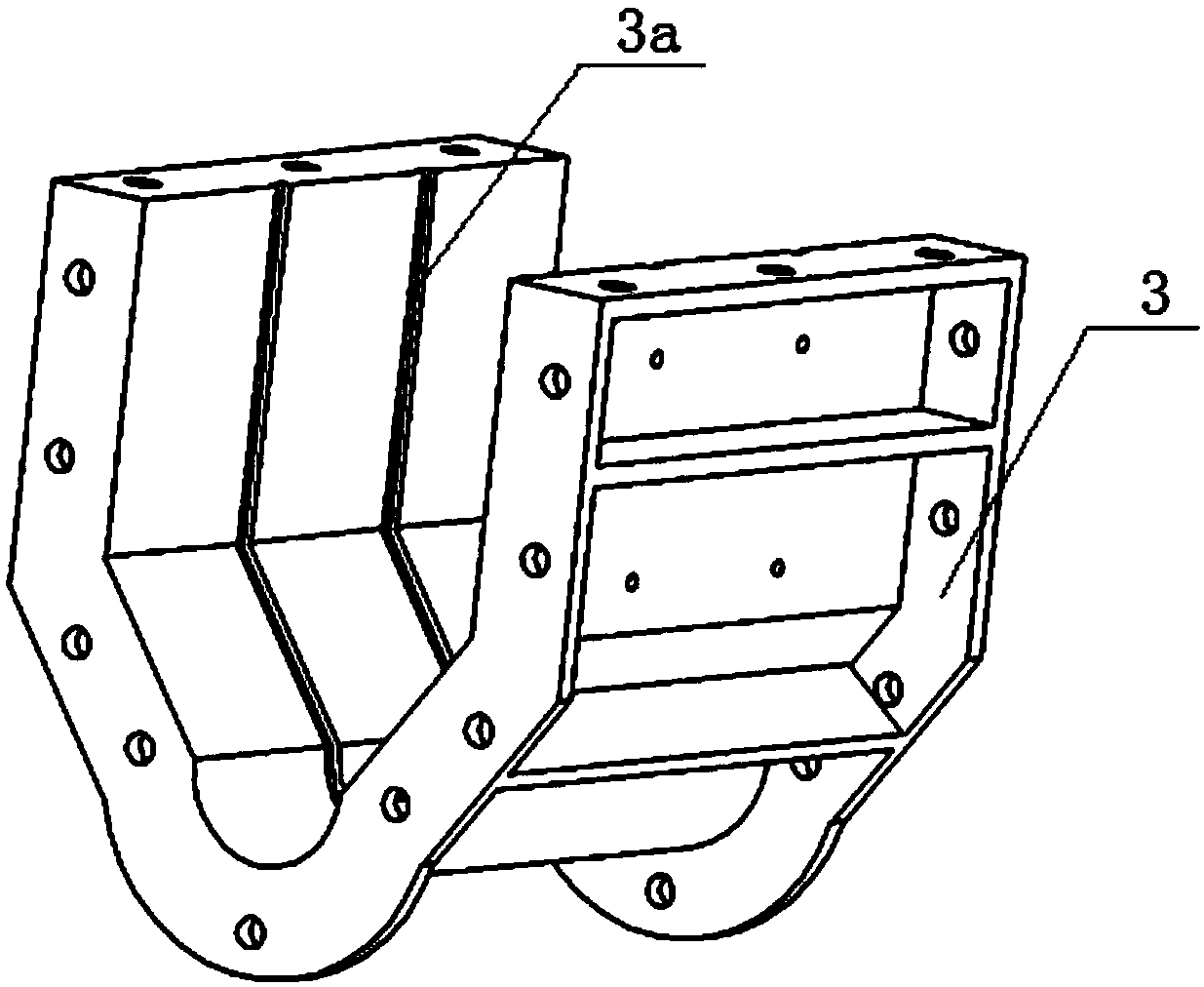

[0030] Such as figure 1 , figure 2 Shown is a double-row quantitative spiral fertilizer device, and the orientations described below are all in accordance with figure 2 The orientation of the schematic diagram includes the housing 20, the left fertilizer discharge interface 1 arranged on the left side plate 2 of the housing, the right fertilizer discharge interface 6 arranged on the right side plate 5 of the housing, and the middle of the housing cavity 21 of the housing 20. The intermediate partition plate composition 14 at the position, the fertilizer distributor 4 arranged on the top surface of the housing 20 and directly above the intermediate partition plate composition 14, and the stirring shaft 8 inserted horizontally into the housing 20 until one end passes through the intermediate partition plate composition 14 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com