Three-dimensional light supplementing lamp

A fill light, three-dimensional technology, applied in the field of lamps, can solve the problem of uneven light receiving of plants, and achieve the effects of being beneficial to plant growth, saving energy, and solving a single lighting method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

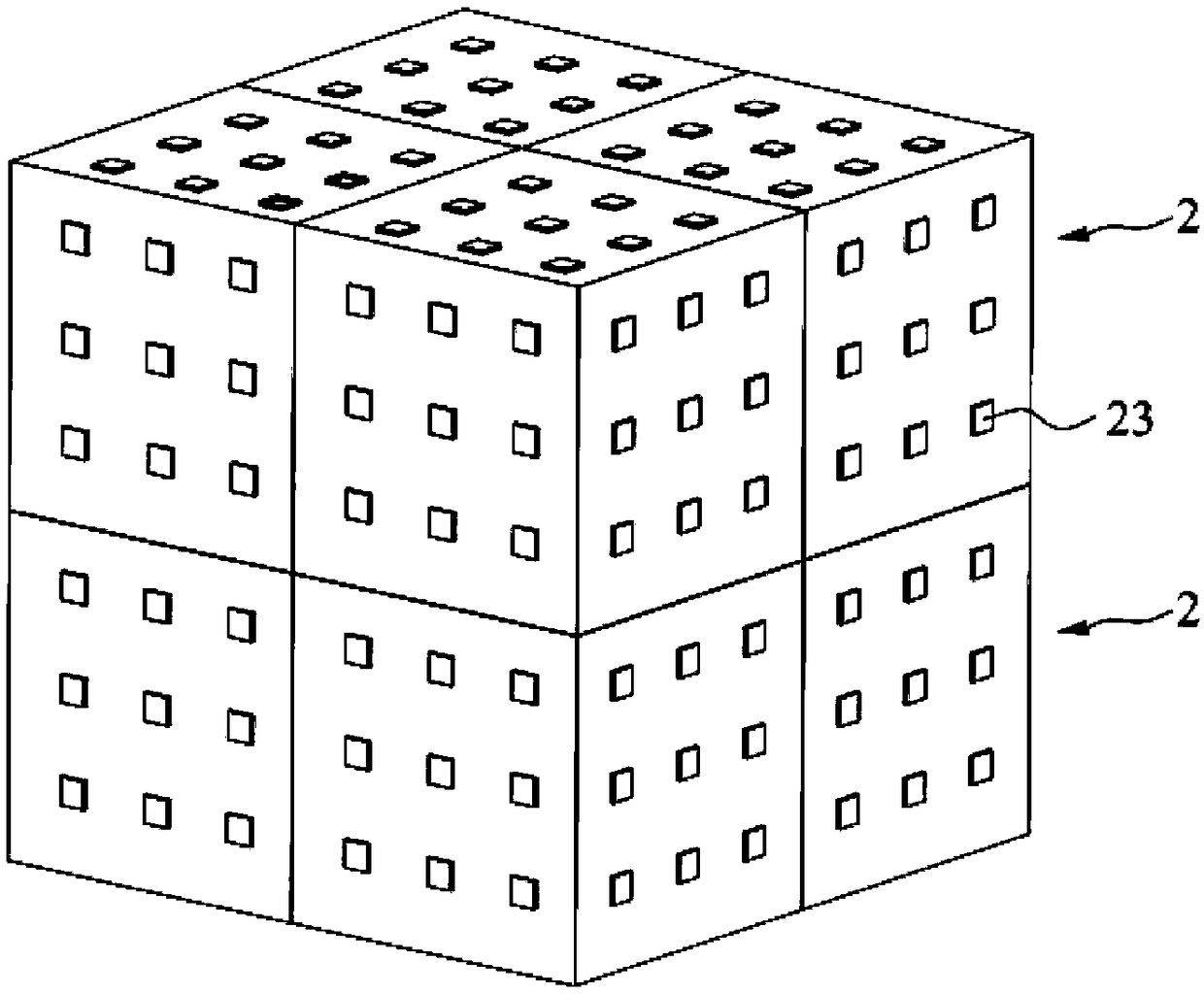

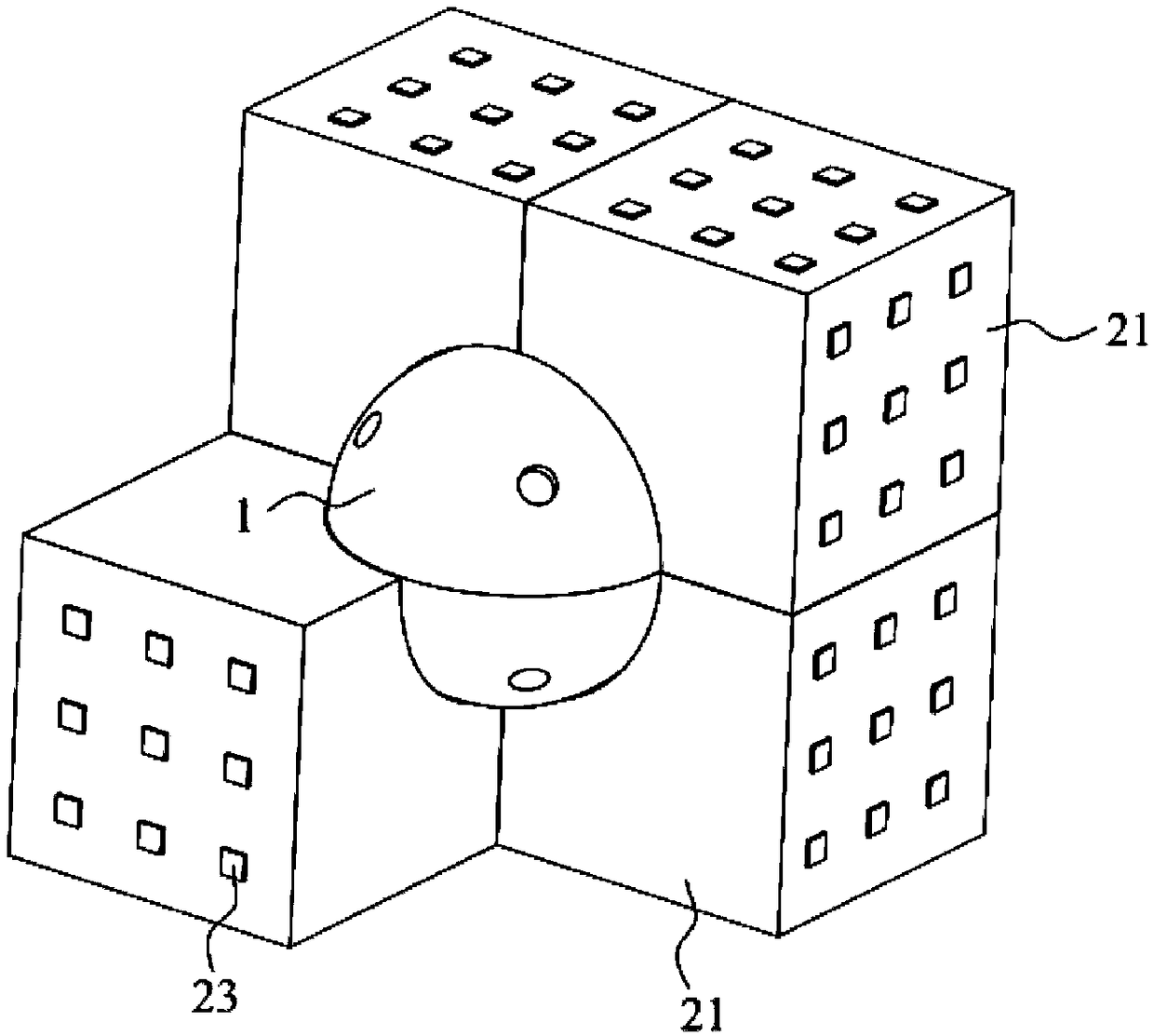

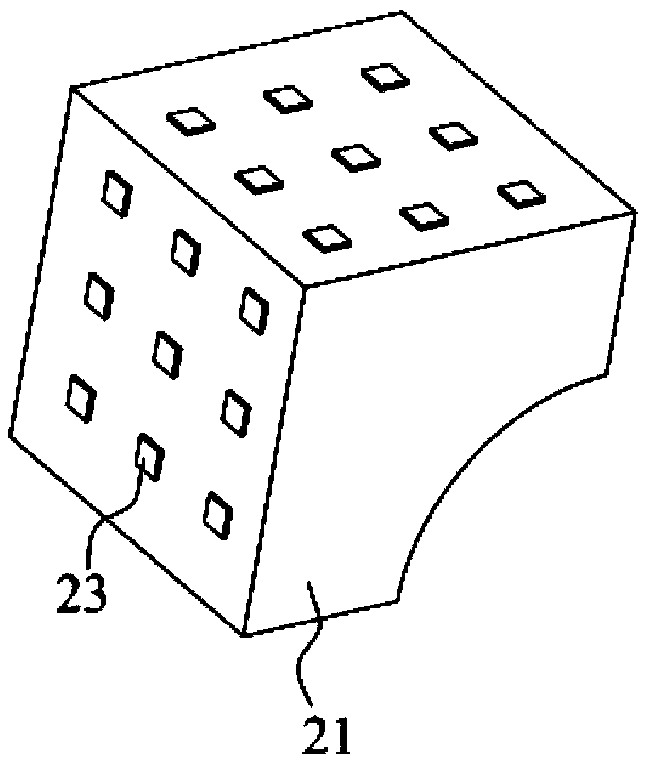

[0040] see Figure 1 to Figure 9 , the embodiment of the present invention provides a three-dimensional fill light, including a support 1 and a light-emitting base 2, the light-emitting base 2 is used for lighting, and the support 1 is used to provide support for the light-emitting base 2, and the three-dimensional fill light can be placed as required Go anywhere on the plant for deep lighting.

[0041] The support 1 includes at least two connecting parts 11, the connecting parts 11 constitute at least part of a sphere, and the connecting parts 11 can rotate around the central axis of the sphere; Several light-emitting substrates 2 are arranged on the axis. Three-dimensional lighting is realized without a reflector, so that the light-emitting base 2 can be illuminated from multiple surfaces and angles, and the plants receive light more uniformly; the connecting part 11 can rotate around the central axis, driving the light-emitting base 2 to rotate, and can realize multi-facet...

Embodiment 2

[0054] Figure 10 to Figure 14 Embodiment 2 is shown, in which components identical or corresponding to those in Embodiment 1 use the same reference numerals as in Embodiment 1. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that the supporting member 1 further includes several fixing parts 12 , connecting parts 11 are arranged between adjacent fixing parts 12 , and the connecting parts 11 and the fixing parts 12 are slidably connected. The setting of the fixing part 12 plays a role of supporting the connecting part 11 and ensures the structural strength.

[0055] Several fixing parts 12 are connected by a bracket 13 , and the bracket 13 includes three supporting shafts 131 connected vertically in pairs, and two ends of each supporting shaft 131 are connected with the fixing parts 12 . The connecting part 11 rotates around one of the supporting shafts 131 . The supporting shaft 131 can be of integral structure or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com