Simple manipulator clamping and turnover mechanism

A technology of turning mechanism and manipulator, which is applied in metal processing and other directions, can solve problems such as limited space, and achieve the effect of simple structure, wide application range and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

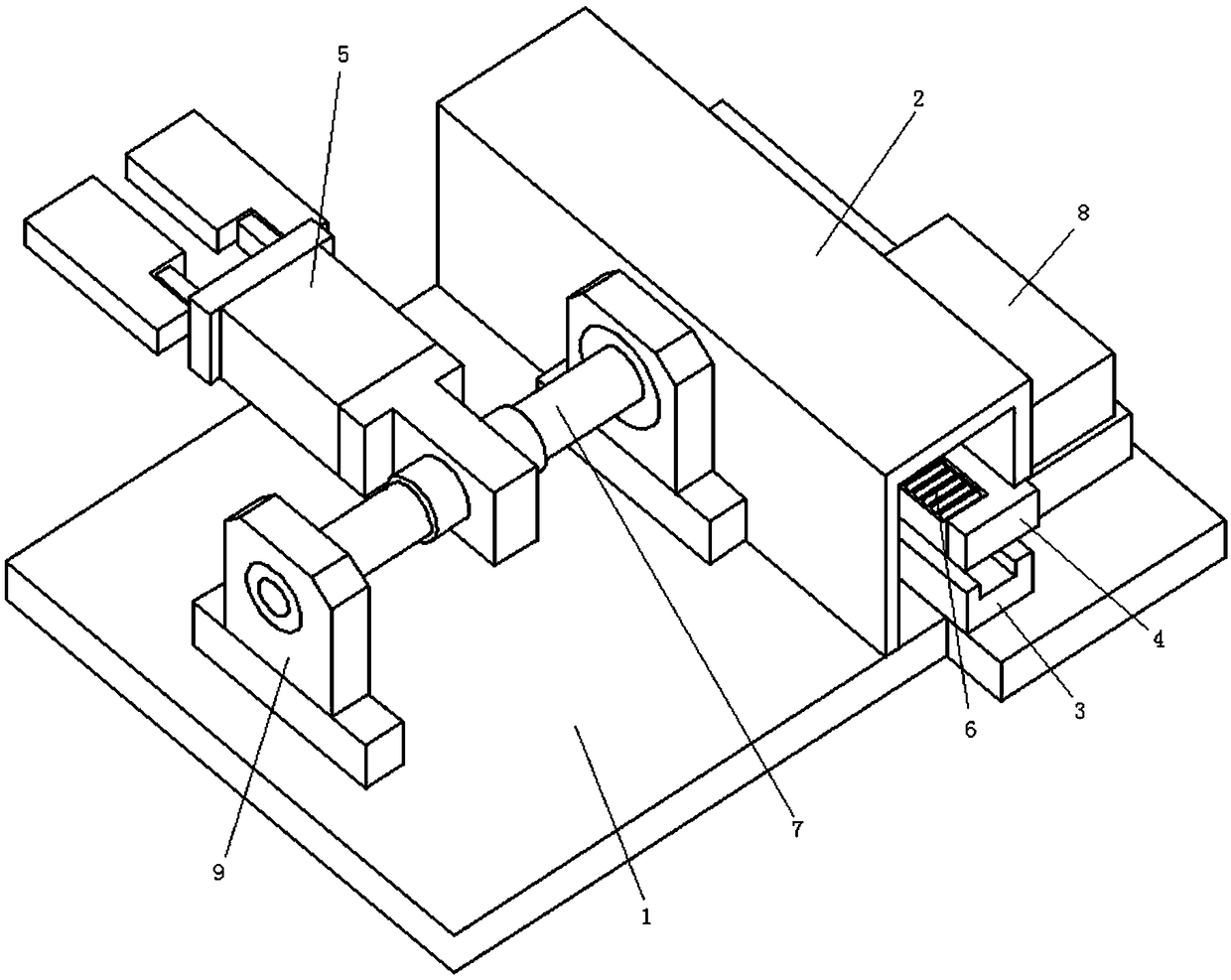

[0012] Attached below figure 1 An embodiment of the present invention is described.

[0013] The simple manipulator grabs and flips the mechanism, which has a mounting panel 1, a cover body 2 is fixed on one side of the upper end of the mounting panel 1, and a guide rail 3 provided on the mounting panel 1 is located in the cover body 2, and the guide rail 3 is fitted with a There is a sliding seat 4 and a rotating device arranged on the installation panel 1 and vertically arranged with the guide rail 3 is fixedly connected with the sliding seat 4, and the end of the manipulator 5 above the installation panel 1 is fixedly connected with the rotating device, and the manipulator is driven by the rotating device 5. After the rotation, the workpiece is turned over after being clamped by the manipulator 5; specifically, the rotating device includes a rack 6, a rotating shaft 7, a telescopic cylinder 8 and a gear, and the rack 6 is arranged in parallel with the guide rail 3 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com