Five-axis robot for material picking and releasing during stamping, and control method thereof

A technology for picking and placing materials for robots, which is applied in the direction of program-controlled manipulators, forging/pressing/hammering machines, manipulators, etc., which can solve problems such as low automation, poor quality stability, and loud working environment noise, and achieve rapid Move, meet product stamping quality and stability requirements, and achieve high-precision positioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

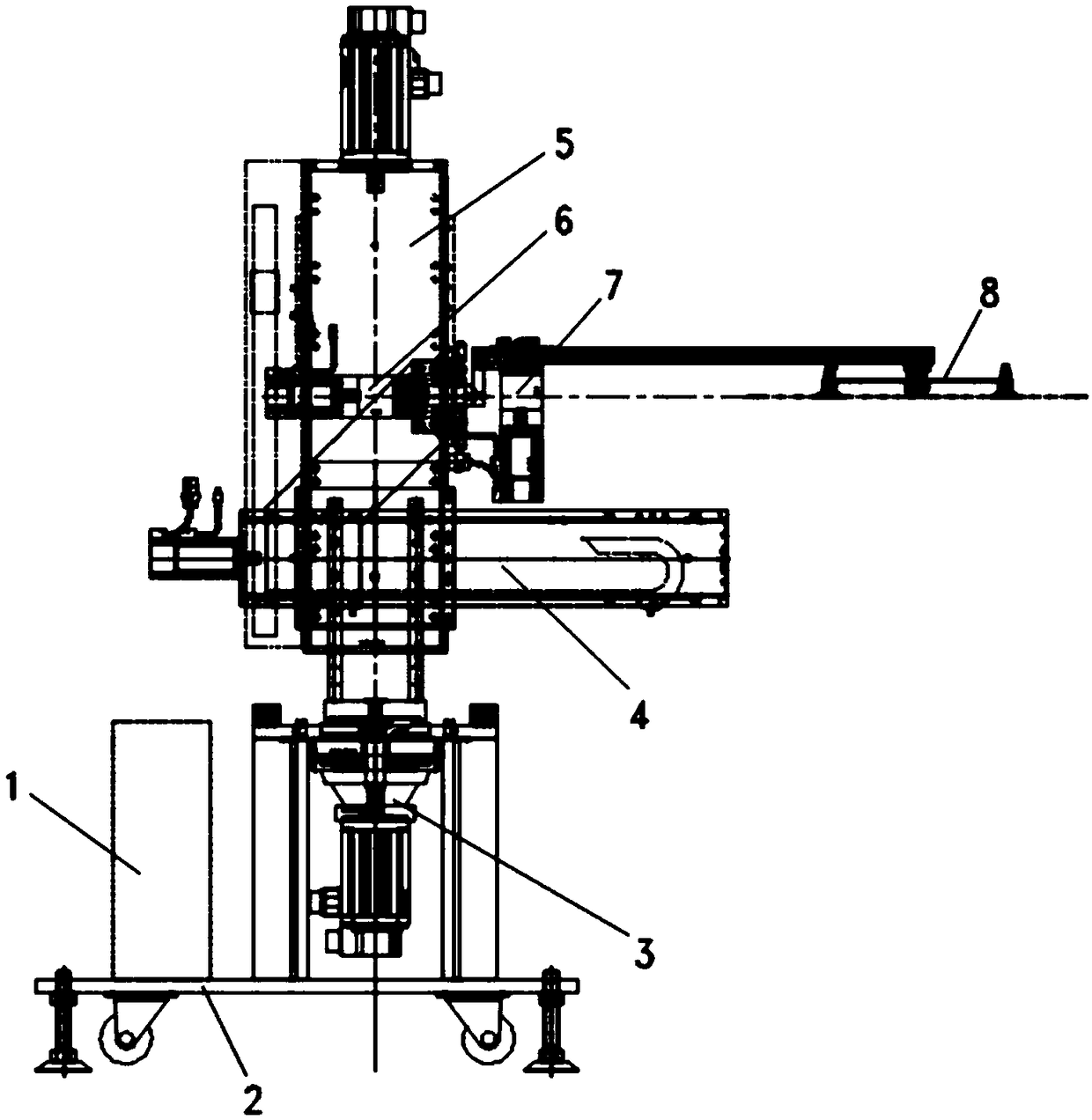

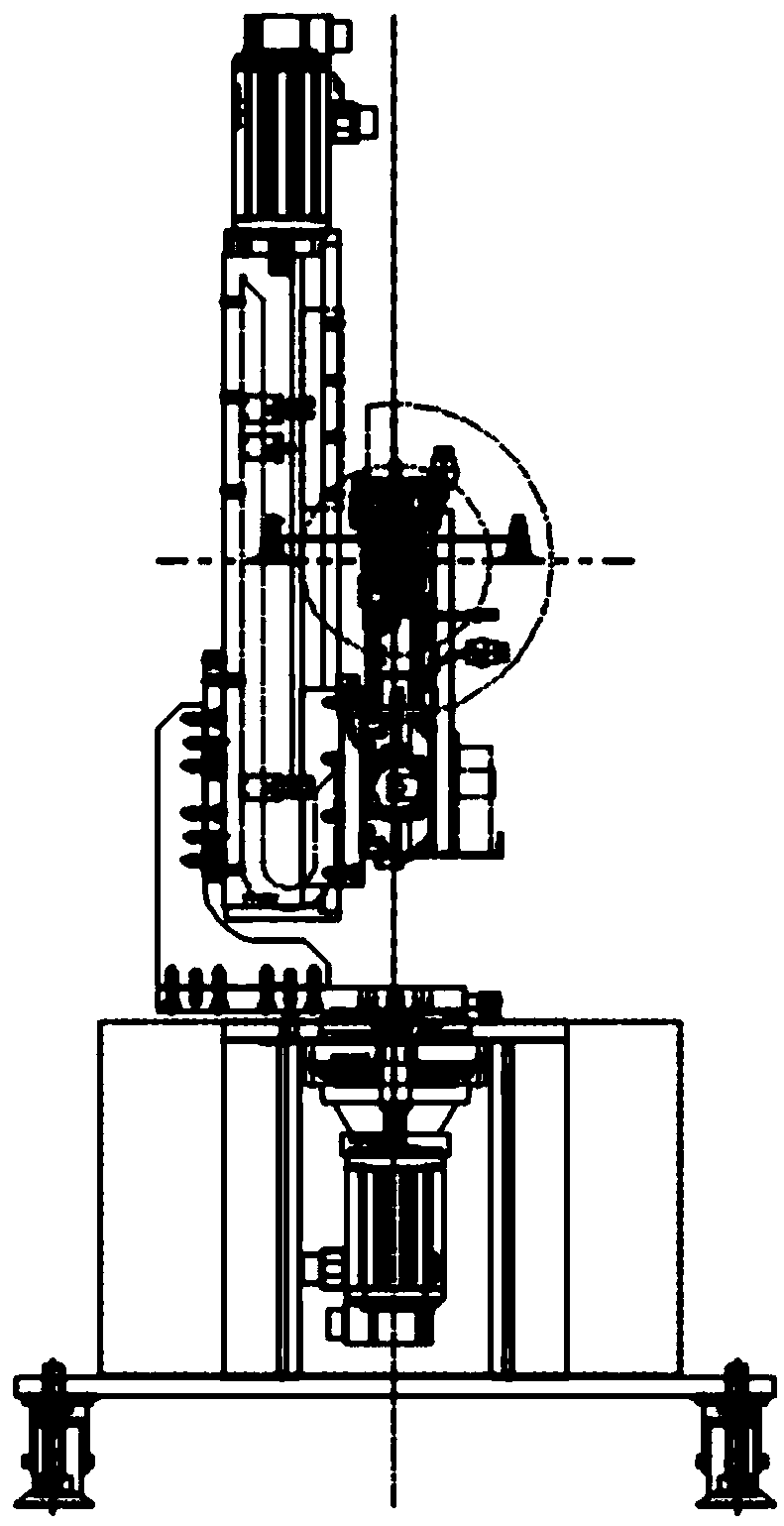

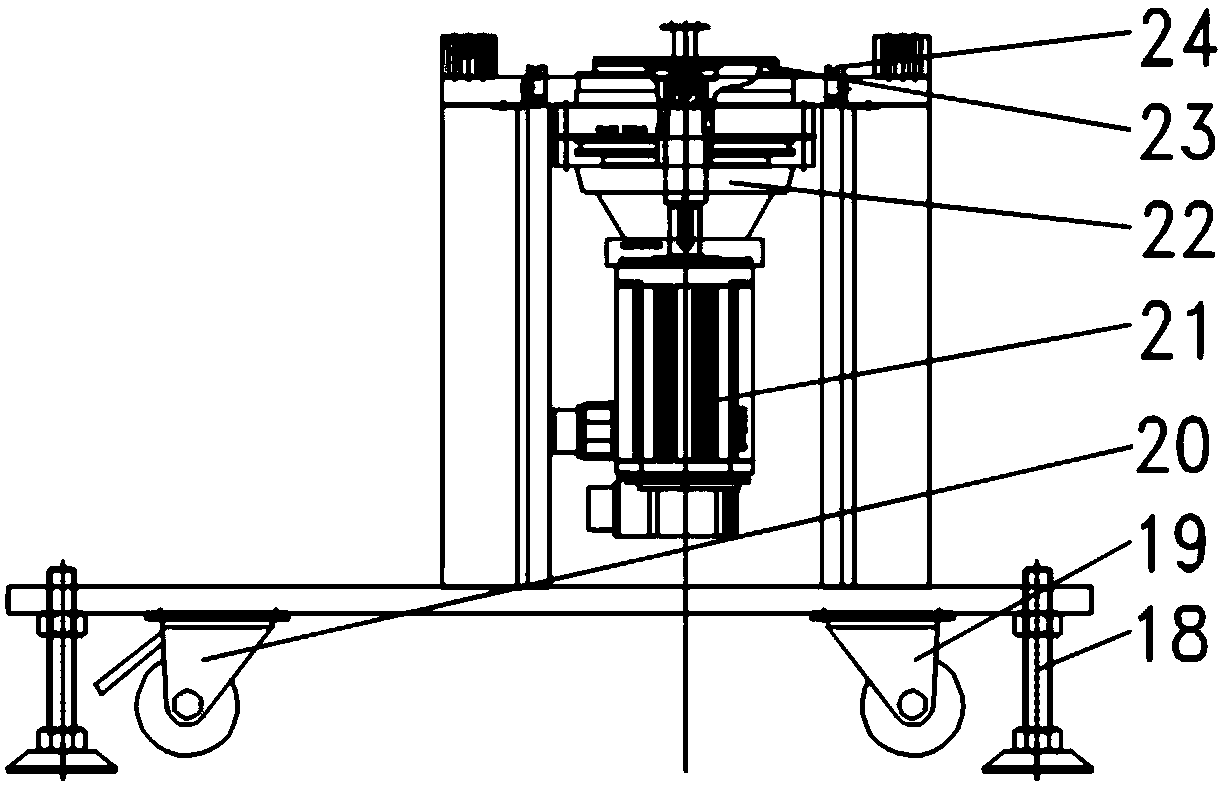

[0044] The present invention proposes a five-axis robot for stamping, picking and discharging materials, such as figure 1 , 2 As shown, it includes a control box 1, a support base 2, a body rotation mechanism 3, a forearm telescopic mechanism 4, an upper arm lifting mechanism 5, a forearm turning mechanism 6, a claw rotation mechanism 7, a claw mechanism 8 and a control panel 9. The panel 9 is connected to the control box 1 by electrical signals; the control box 1 is connected to the body rotation mechanism 3, the forearm telescoping mechanism 4, the upper arm lifting mechanism 5, the forearm turning mechanism 6 and the claw rotation mechanism 7. Servo motors and their drivers and induction switch signals Electrically connected, and electrically connected with the claw mechanism 8; the control panel 9, the control box 1 and each mechanism are located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com