Circuit board printing device for mobile phone production

A technology for printing devices and circuit boards, applied in printing, printing machines, printing processes, etc., can solve the problems of solder paste scratches on circuit boards, affecting product quality, and low reliability in use, preventing tin bridges and improving practicability. , the effect of improving the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

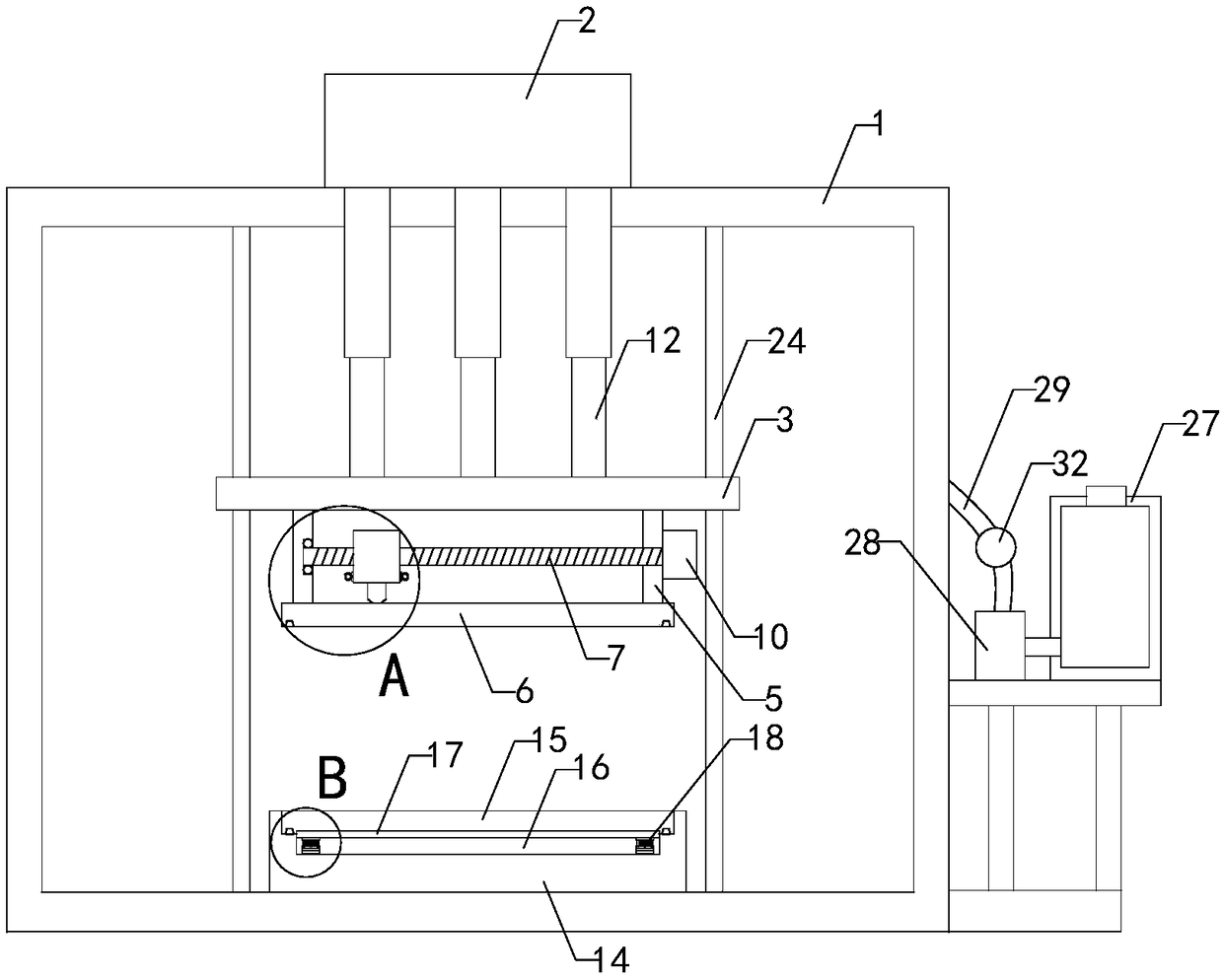

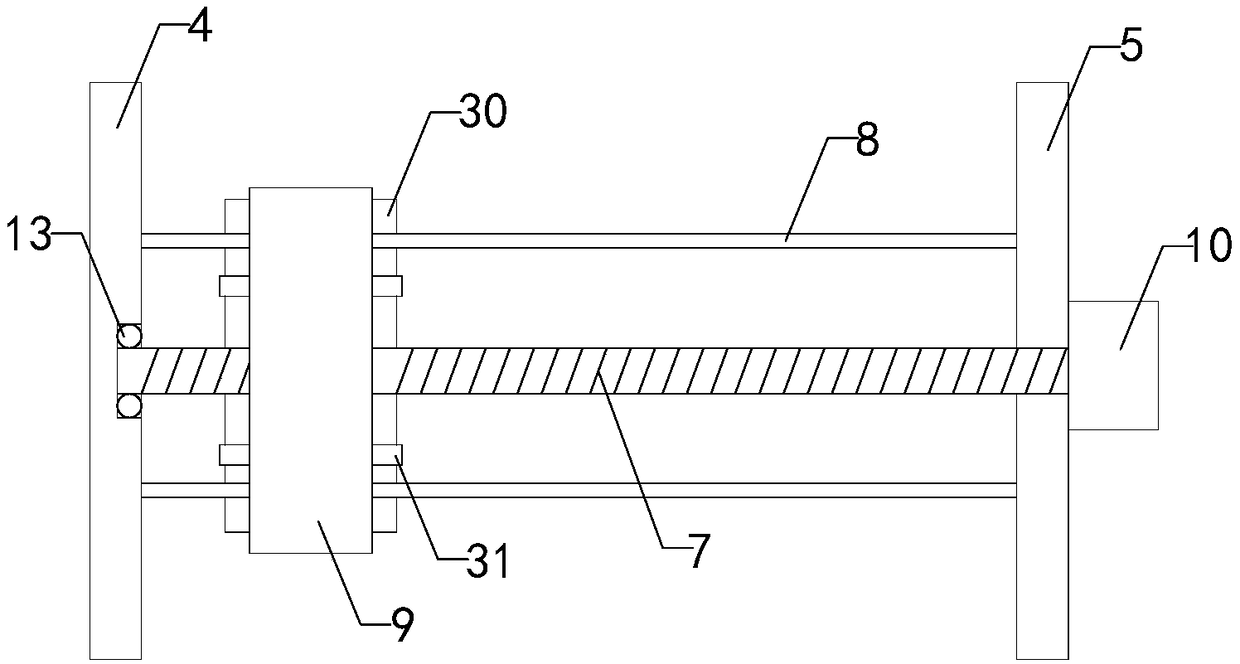

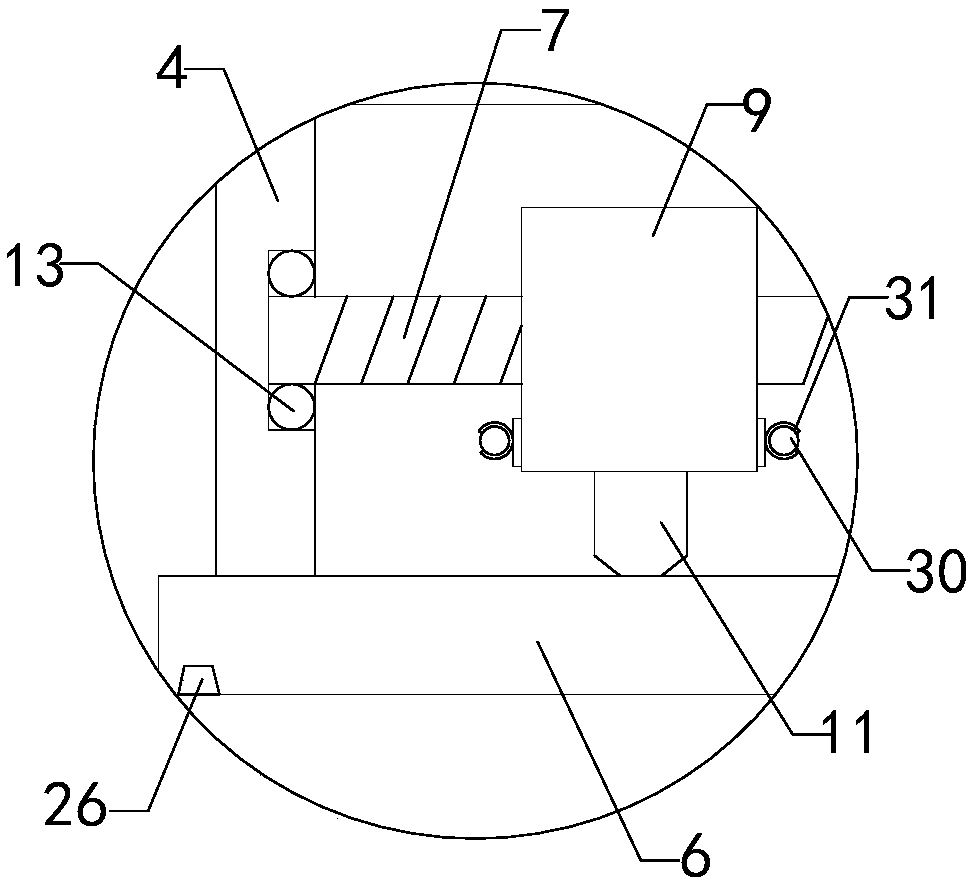

[0017] Such as Figure 1 to Figure 4 As shown, a circuit board printing device for mobile phone production of the present invention includes a box body 1 and a hydraulic cylinder 2. A working chamber is arranged inside the box body, and a top plate 3, a left support plate 4, a right Support plate 5, mask 6, lead screw 7, two sets of limit rods 8, slider 9, motor 10 and scraper 11, the hydraulic cylinder is installed on the top of the box, and a hydraulic pressure Rod 12, the bottom end of the hydraulic rod stretches into the working cavity from the top of the box body and is connected with the top of the top plate, the tops of the left support plate and the right support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com