Upper-traction adjusting type assembled cofferdam

A combined cofferdam and adjustment technology, applied in construction, infrastructure engineering, etc., can solve the problems of not well matched slope slope, leakage of cofferdam side walls and slopes, etc. The overall connection strength and the overall structure are simple and stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

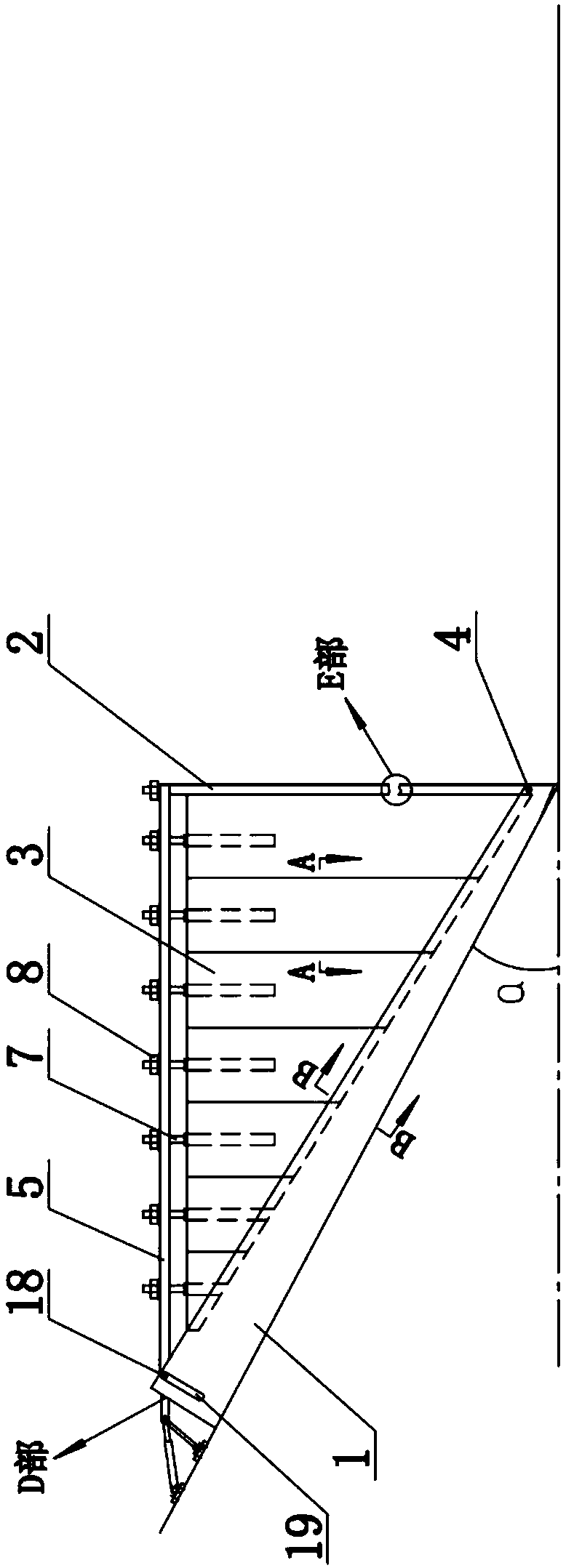

[0022] Embodiment 1: The main body of the combined cofferdam includes a wading bottom wall 2 and two side walls 3, and also includes structural components such as an adjustment seat, a U-shaped upper draw beam 5, and a U-shaped parallel clamping seat 1.

[0023] Wherein, the wading bottom wall 2 is an integrated wallboard, or a combined wallboard composed of multiple bottom boards butted in sequence, and a convex-concave clamping structure 9 and a sealing water-stop layer are arranged on the butt joint surface. The side walls 3 may also be integral triangular wall panels, or may be composed of a plurality of side panels butted in sequence, and a convex-concave clamping structure 9 and a sealing water-stop layer are arranged on the butted surfaces. The sealing water-stop layer is usually sealed with a rubber layer. The purpose of the combined wading bottom wall 2 and side walls 3 is to provide convenience for transfer after disassembly.

[0024] set a like Image 6 A U-shaped...

Embodiment 2

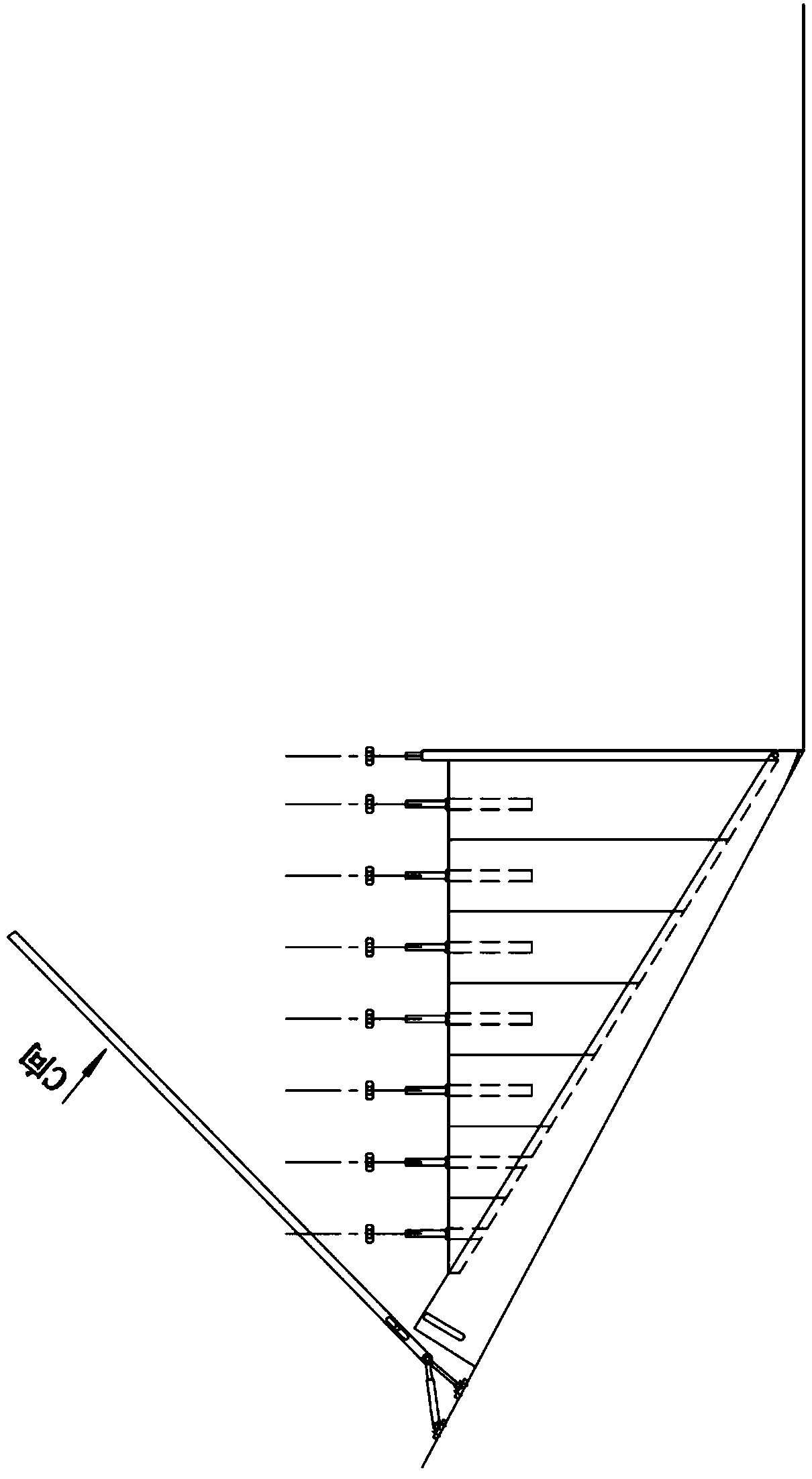

[0028] Embodiment 2: The two side walls 3 of the embodiment 1 are composed of multiple side plates connected in sequence, and on the basis of setting the convex-concave clamping structure 9 and the sealing water-stop layer on the butt surface, the side walls 3 are set to be freely adjustable structure. Such as Figure 4 As shown, two adjacent side panels are convex-convex butted, so that the side panels are mutually restrained and can only slide vertically. Vertical sliding is allowed, and the height adjustment of the side wall 3 can be realized by using vertical sliding, and multiple side plates are respectively inserted into the U-shaped parallel deck 1 below it, regardless of the angle of the U-shaped parallel deck 1 with the slope angle How to change, each side plate can reach the ability of inserting U-shaped parallel deck 1, can be fixed with inner sealing waterproof layer 11 on the two inner sidewalls of U-shaped parallel deck 1, thereby realize the sealing of side wal...

Embodiment 3

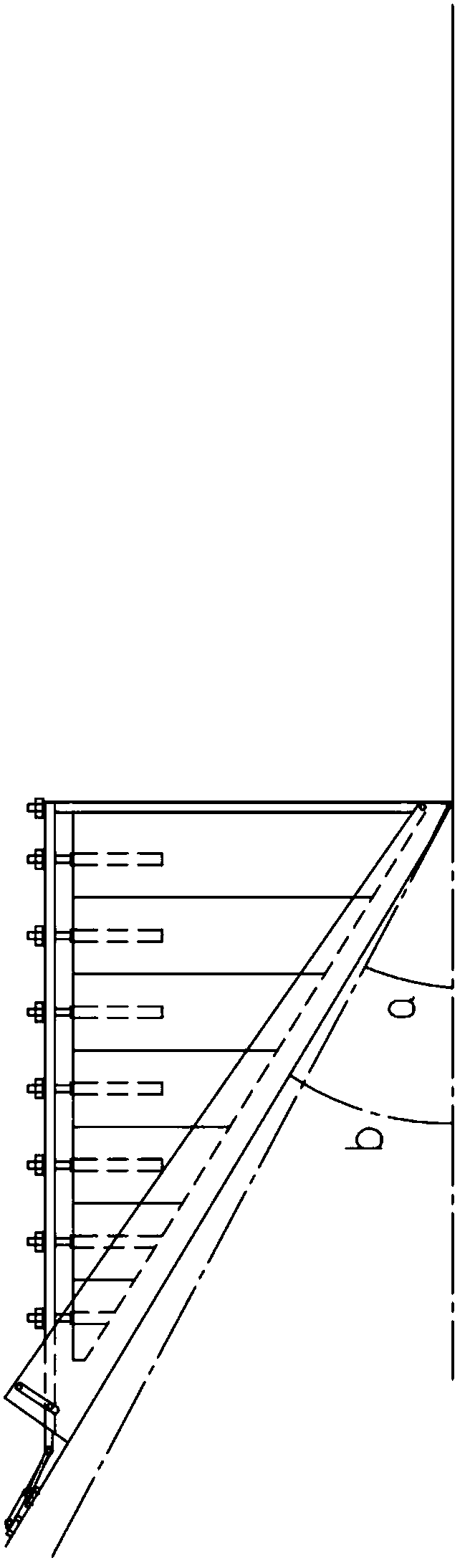

[0030] Embodiment 3: On the basis of Embodiment 1, the adjustment and positioning of the U-shaped parallel deck 1 and the U-shaped upper draw beam 5 are carried out. The non-wading end of the U-shaped parallel deck 1 is provided with a vertical sliding hole 18 perpendicular to its bottom surface, and horizontal sliding holes 17 are respectively provided on both sides of the U-shaped upper drawing beam 5 near the hinged end. The U-shaped parallel deck 1 is not The vertical sliding hole 18 at the wading end is hinged in the horizontal sliding hole 17 of the U-shaped parallel clamp 1 through a sliding shaft 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com