Upright counterweight lightweight mobile cofferdam

A counterweight and lightweight technology, applied in construction, infrastructure engineering, etc., to achieve the effect of easy transportation, simplified components, and easy assembly and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

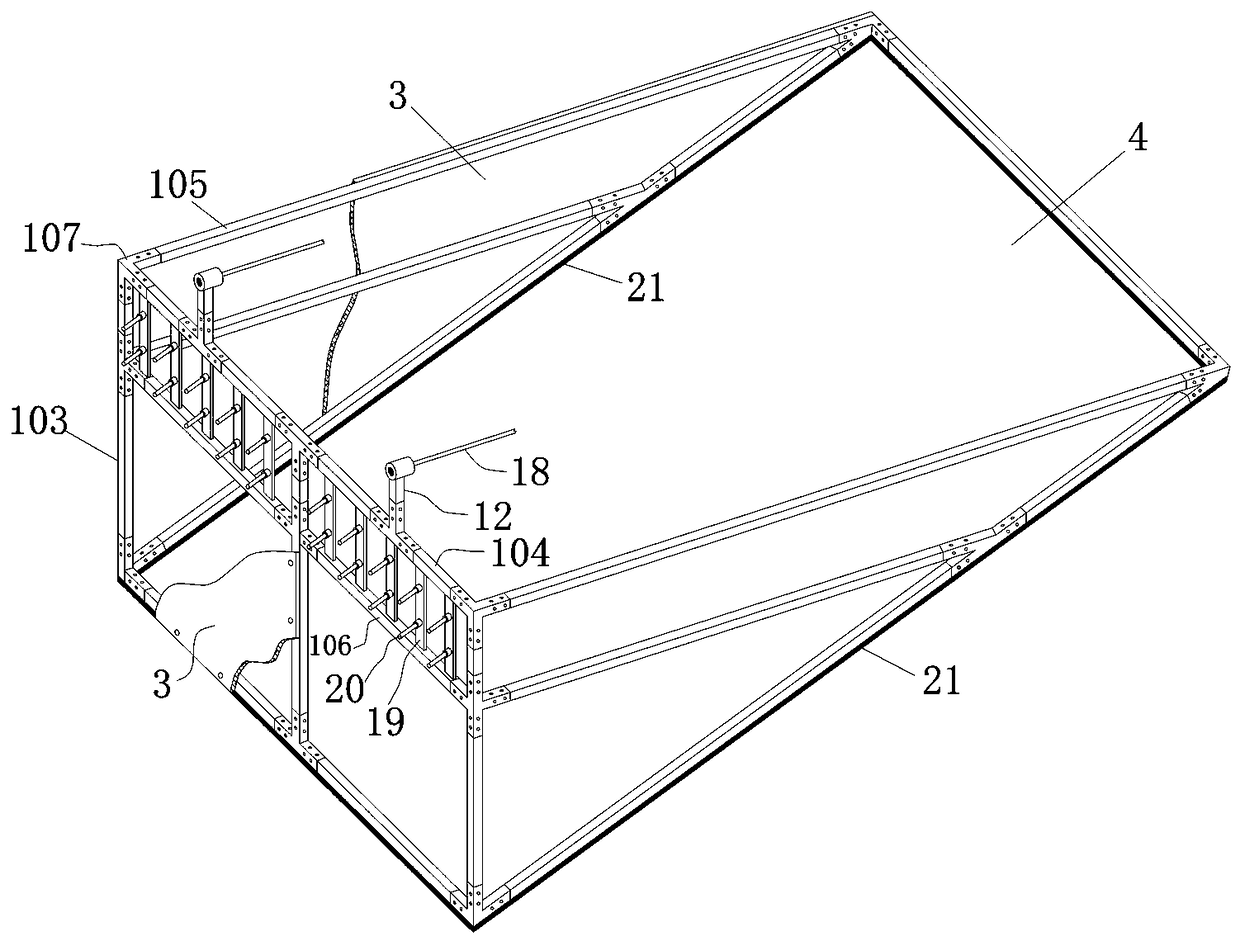

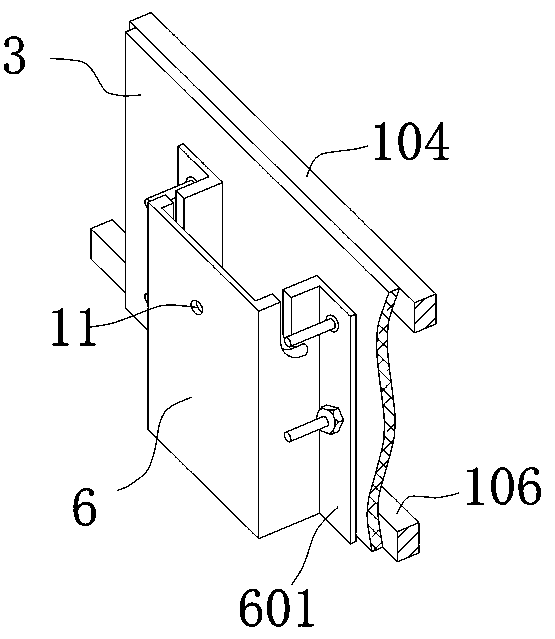

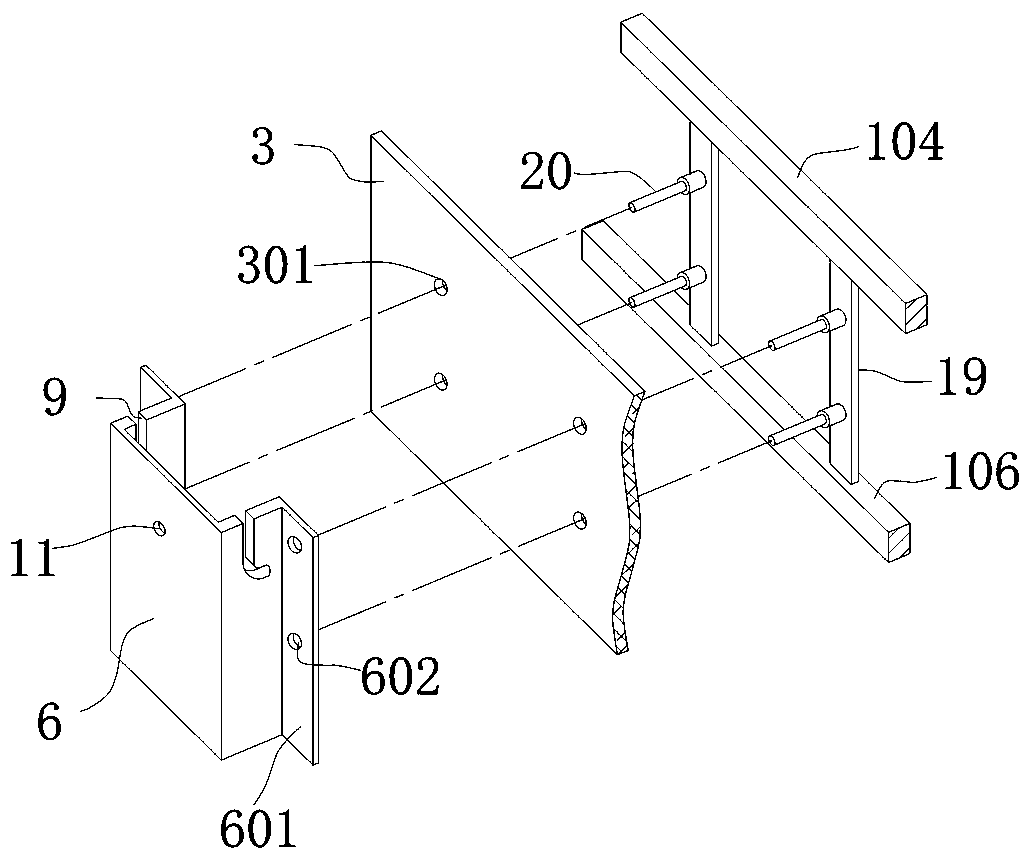

[0026] Embodiment 1: a kind of upright counterweight type lightweight mobile cofferdam, such as figure 1 As shown, the main frame includes wading columns 103, crossbeams 104, side beams 105, and auxiliary beams 106 parallel to the crossbeams 104, etc. are interconnected to form a frame structure. The upper ends of the wading columns 103 on both sides are fixed with the crossbeam 104 and the auxiliary beam 106 through the corner connectors 107, and the lower ends are fixed with the bottom connecting rods through the corner connectors 107, and then the water retaining panels are fixed to form a wading wall. The cross beam 104, the side beam 105 and the side bottom bar form a triangular side frame, and then the water retaining panel is fixed to form a side wall. The main structure of the cofferdam is surrounded by the associated wading walls and side walls, and the inner side is the working area. In addition, a skirt-type water-stop rubber pad is installed on the lower edge of e...

Embodiment 2

[0030] Embodiment 2: another kind of upright counterweight type lightweight mobile cofferdam, such as Figure 4-8As shown, the main frame 1 is included, the main frame is equipped with a traction end 12, the traction end is a steel pipe, and the upper end of the traction end 12 is connected and fixed with the fixed pile 14 on the horseway 13 by a steel cable 18, so as to prevent the cofferdam from being damaged due to its own weight and upstream water flow. The horizontal thrust slides on the bank slope 15 to improve the overall anti-skid performance of the cofferdam; the main frame 1 is a triangular prism frame, and the triangular prism is placed horizontally, that is, the side edges of the triangular prism are set horizontally. In this embodiment, the main frame 1 is Right-angled triangular prism frame, the left and right sides of the triangular prism are right-angled triangles parallel to each other, and the upper surface 101 of the main frame is perpendicular to the rear fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com