Adjustable spraying roller brush

A roller brush and adjustable technology, which is applied in the direction of construction and building structure, can solve the problem that the roller brush needs to be repeatedly dipped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

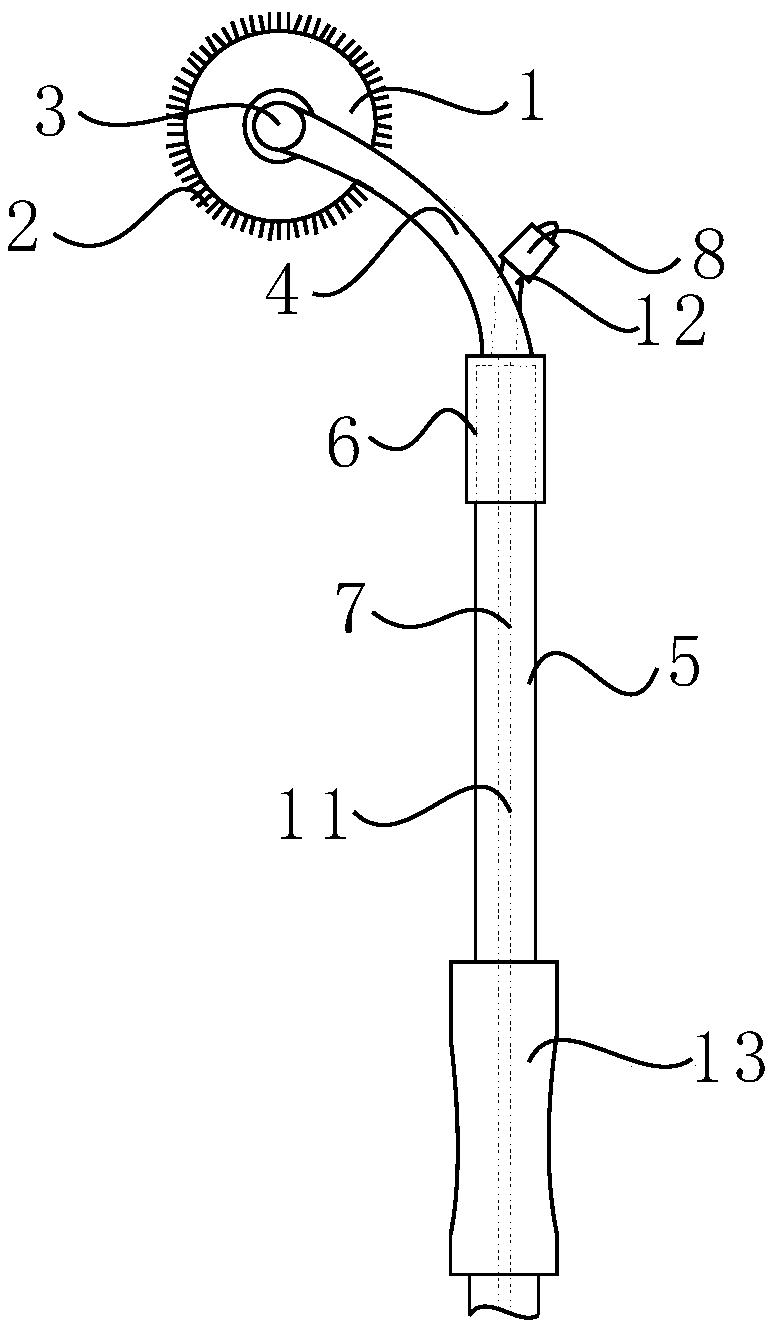

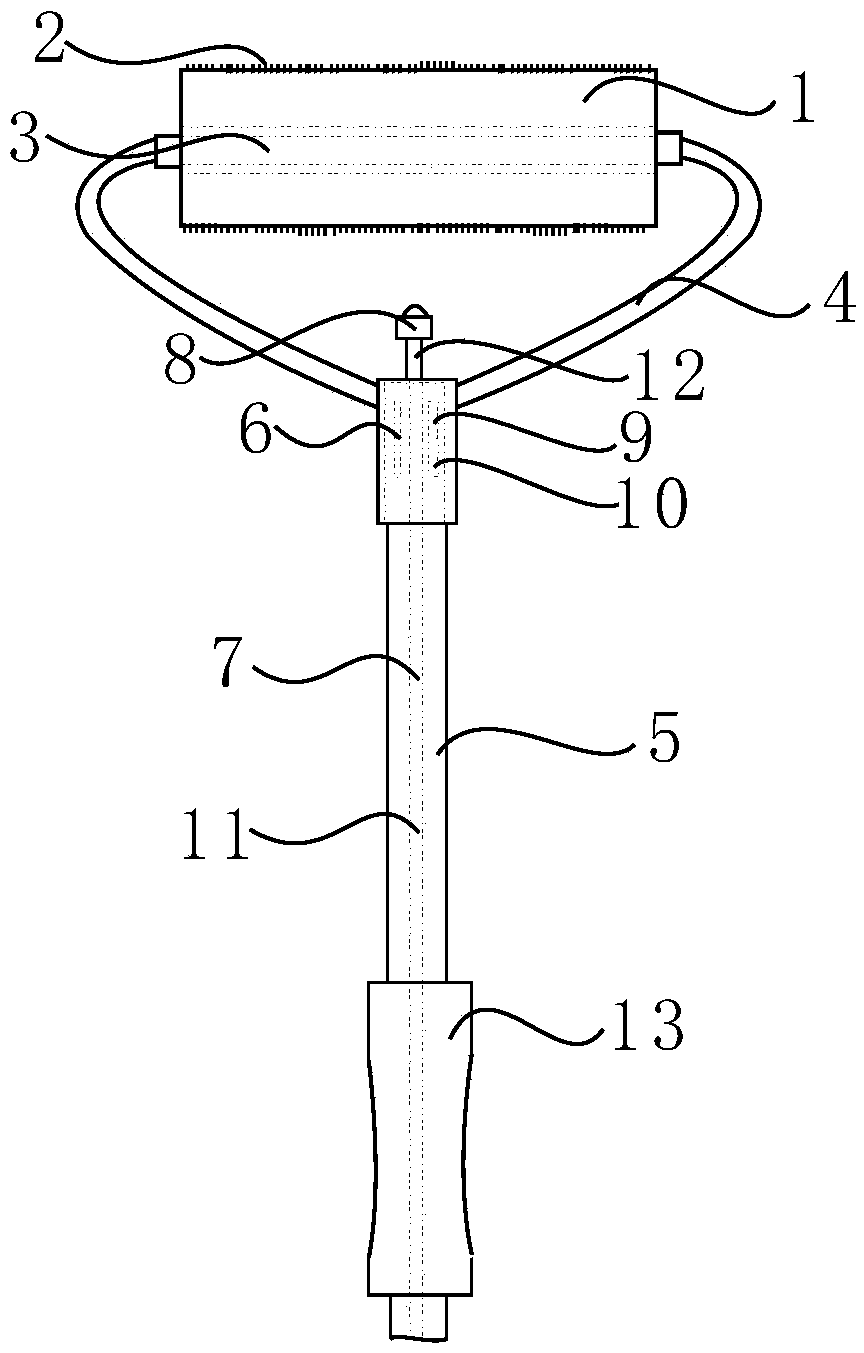

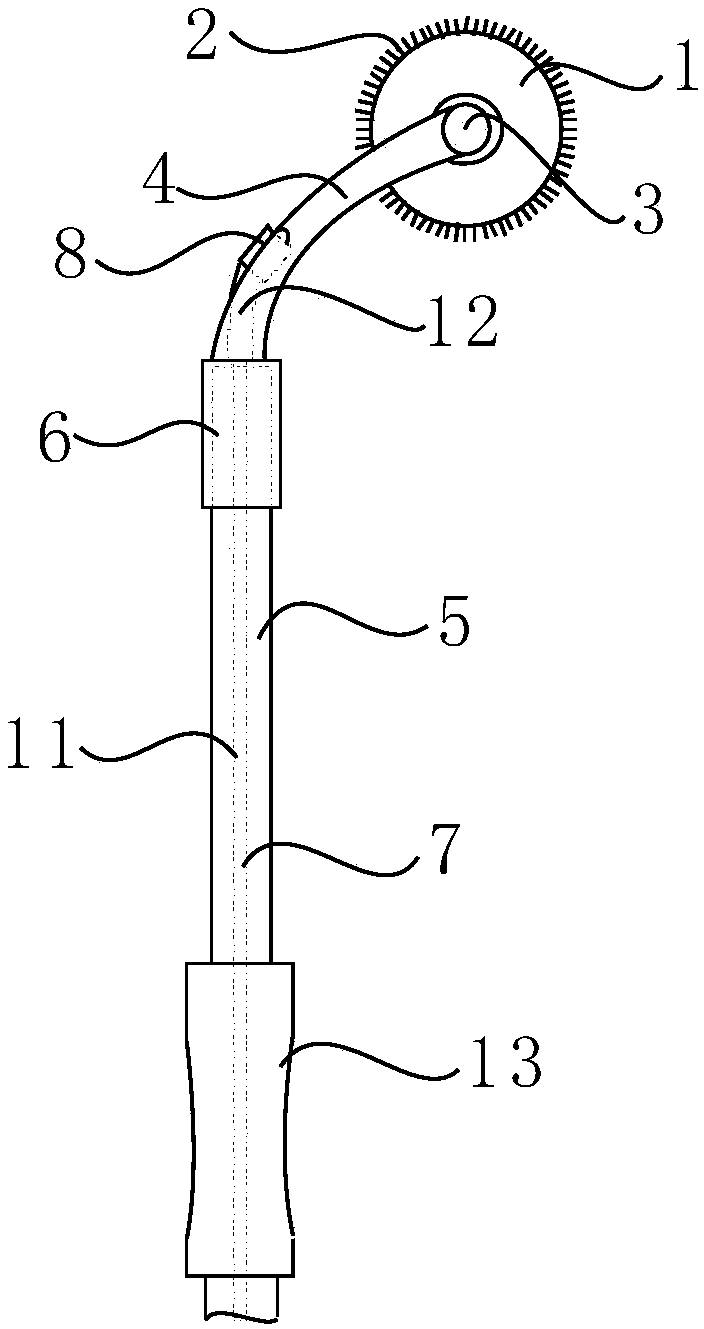

[0017] As shown in the figure, the present invention provides an adjustable spraying roller brush, which includes a roller 1 and a bristle 2 fixedly connected to the outer surface of the roller 1, and also includes a roller 3, a support frame 4, a connecting rod 5 and a spraying mechanism. The shaft 3 runs through the roller 1, the roller 3 supports the rotation of the roller 1 around the roller 3, the support frame 4 is connected with both ends of the roller 3, the lower end of the support frame 4 is clamped on the upper part of the connecting rod 5 through the adjustment mechanism 6, the spraying mechanism includes a power The pipeline 7 connected to the device and the nozzle 8 connected to the pipeline 7, the pipeline ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap