Anti-rust tapping screw

A self-tapping screw and screw technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of reduced tightening effect, difficulty in disassembling screws, and unsatisfactory anti-rust layer effect, and achieves improved sealing effect and good anti-rust performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

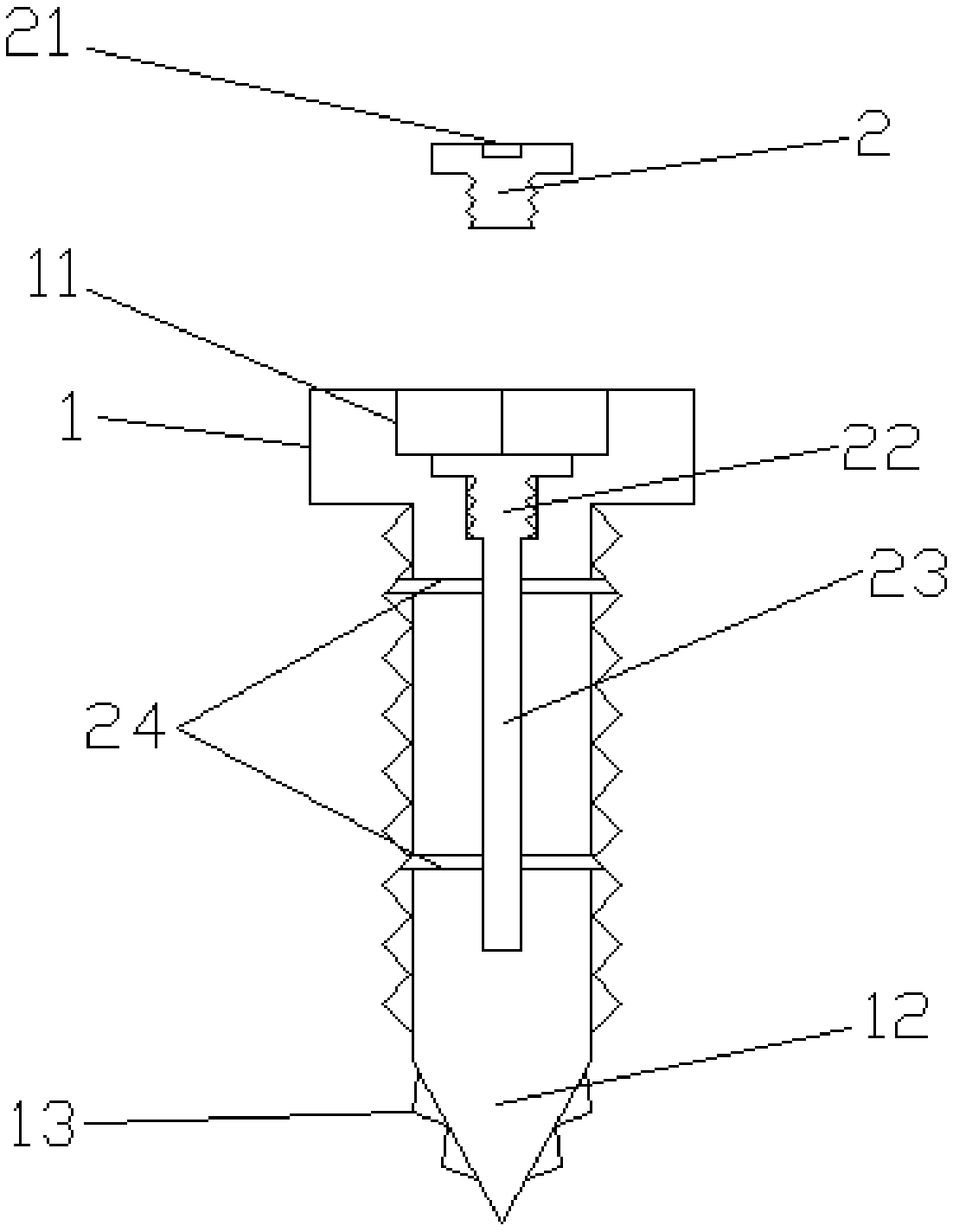

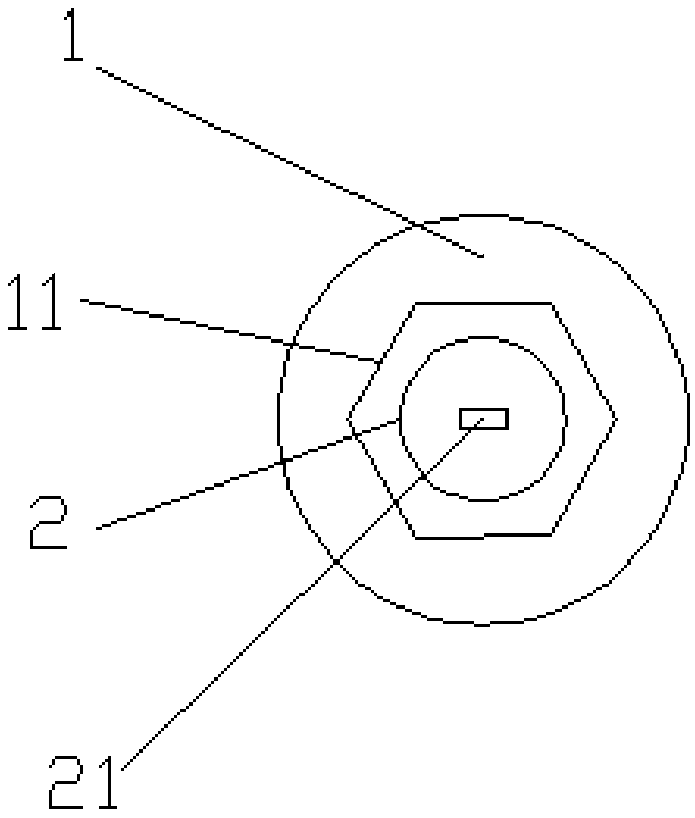

[0015] refer to figure 1 , a rust-proof self-tapping screw of the present invention, comprising a screw body 1, the screw body 1 is composed of a screw head and a screw rod, the screw head is provided with a screw tightening groove 11, and the lower end of the screw rod is provided with a screw point 12. A self-tapping thread 13 is provided on the outer wall of the screw tip 12, an oil injection hole 22 is provided at the center of the screw head, an internal thread is provided in the oil injection hole 22, and an oil storage tank 23 is provided at the center of the screw rod. The oil injection hole 22 communicates with the oil storage tank 23. The oil storage tank 23 is provided with a number of oil guide channels 24. The oil guide channels 24 radially penetrate the screw rod and communicate with the outside of the screw rod. The oil injection hole 22 is equipped with A seal bolt 2 corresponding in size and shape, the outside of the seal bolt 2 is provided with an external th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com