Locking nut

A locking nut, locking technology, applied in the direction of nuts, locking fasteners, screws, etc., can solve the problems of poor rust prevention effect of nuts, and achieve the effect of improving sealing, avoiding relative rotation, and improving locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

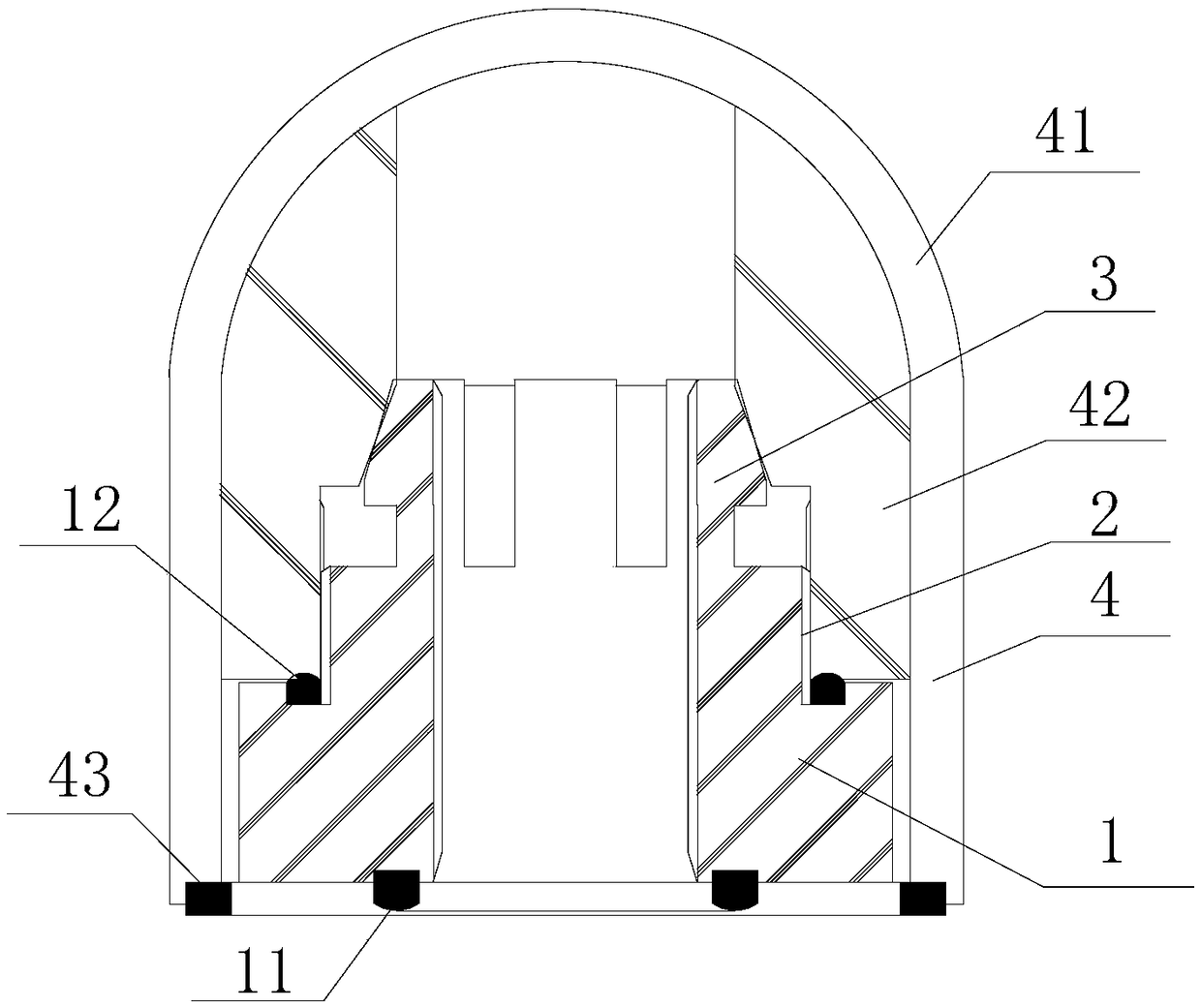

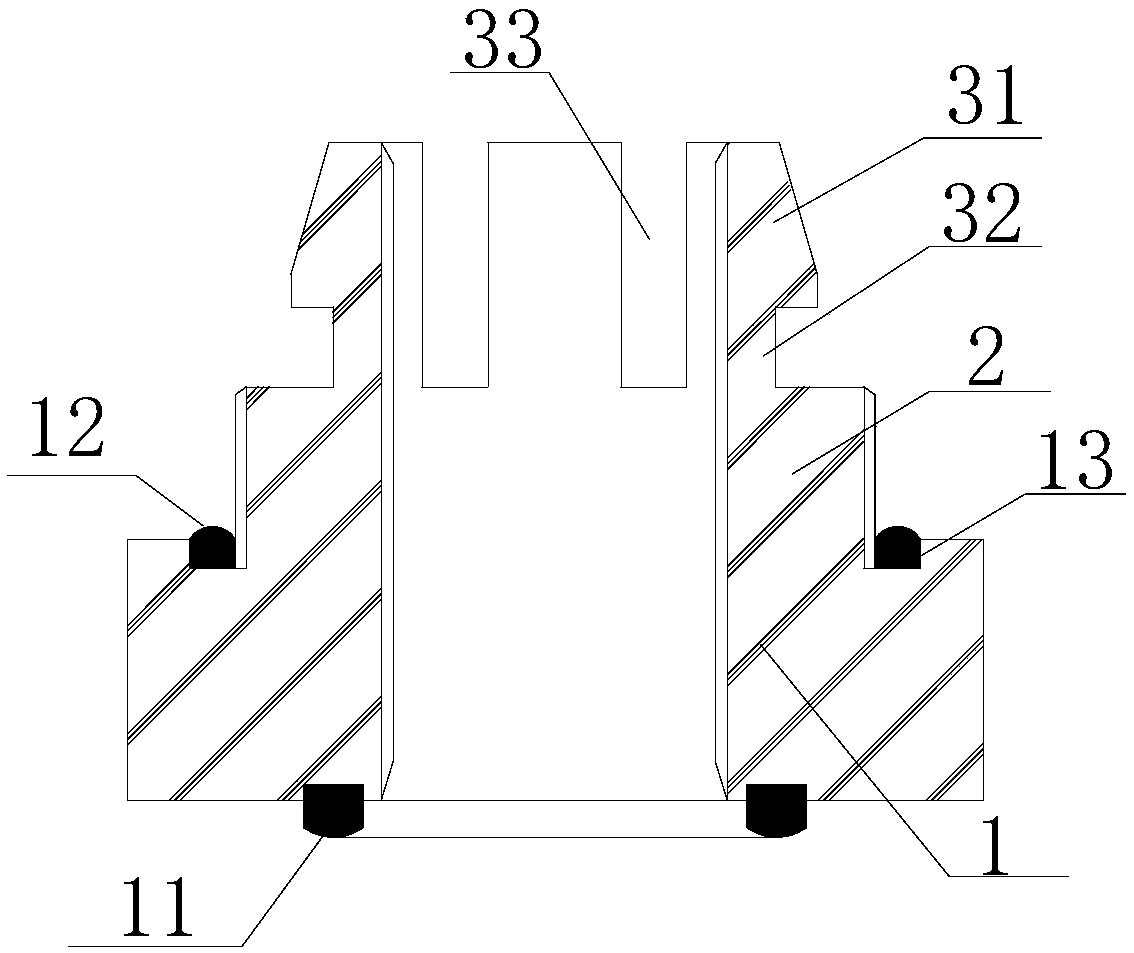

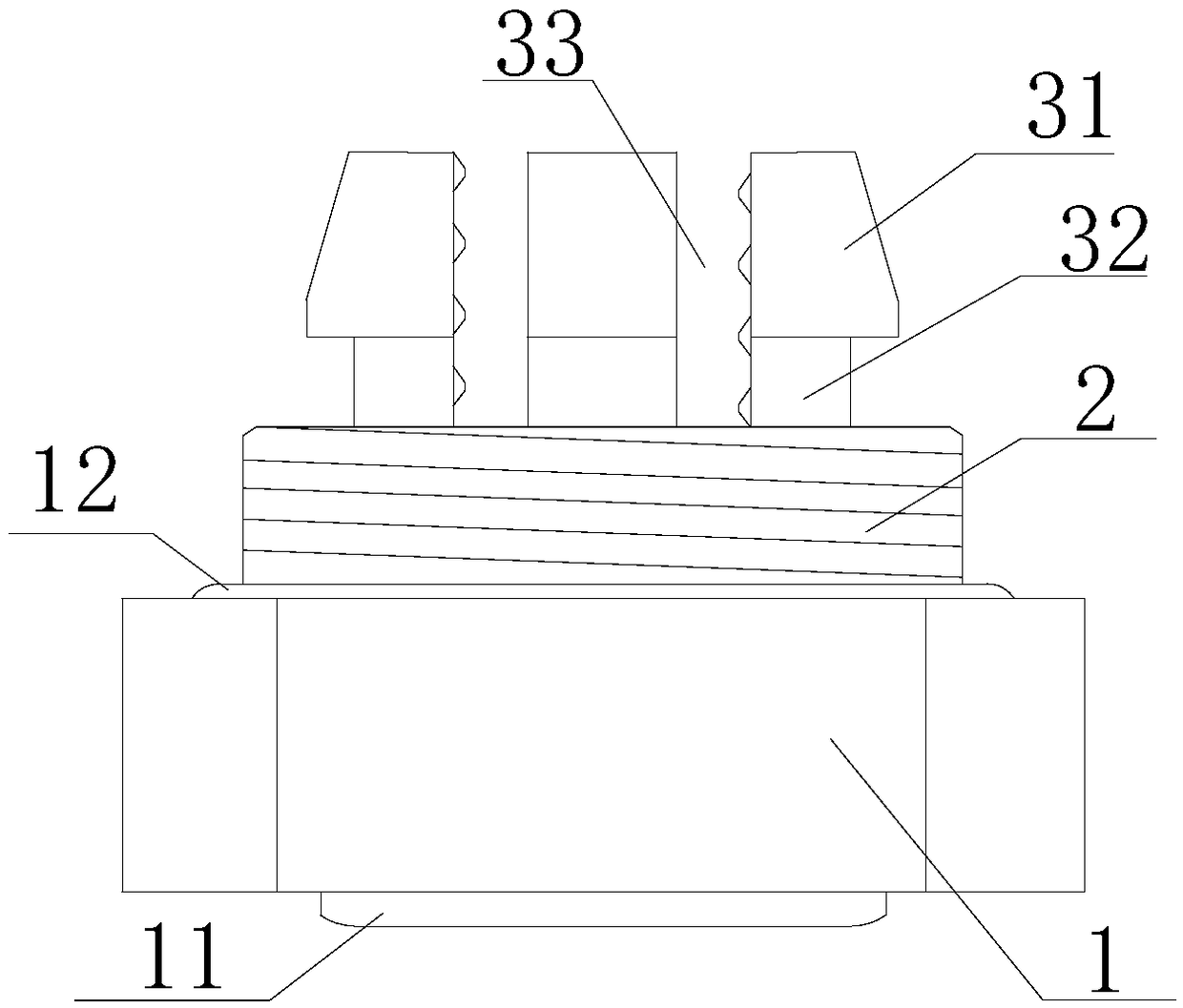

[0015] refer to Figure 1 to Figure 4 , a lock nut of the present invention, comprising a hexagonal nut body 1, a connecting body 2, a locking body 3 and a protective cover 4, a connecting body 2 is arranged above the hexagonal nut body 1, and an outer wall of the connecting body 2 is provided There are threads, and the inner wall of the protective cover 4 is provided with a mounting flange 42, and the mounting flange 42 includes a mounting portion 421 and a driving portion 422, and the inner wall of the mounting portion 421 is provided with threads, and the connecting body 2 and the mounting The connecting parts 421 are threadedly connected and matched, and the locking body 3 is provided above the connecting body 2, and the locking body 3 cooperates with the driving part 422, and the driving part 422 controls the radially retracting of the locking body 3. The locking bodies 3 are evenly distributed around the circumference, slots 33 are arranged between the locking bodies 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com