A wavy tube wrap-around gas inertial capacity

A wave-shaped, wrap-around technology, used in liquid shock absorbers, springs/shock absorbers, shock absorbers, etc., to solve problems such as high nonlinearity and kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

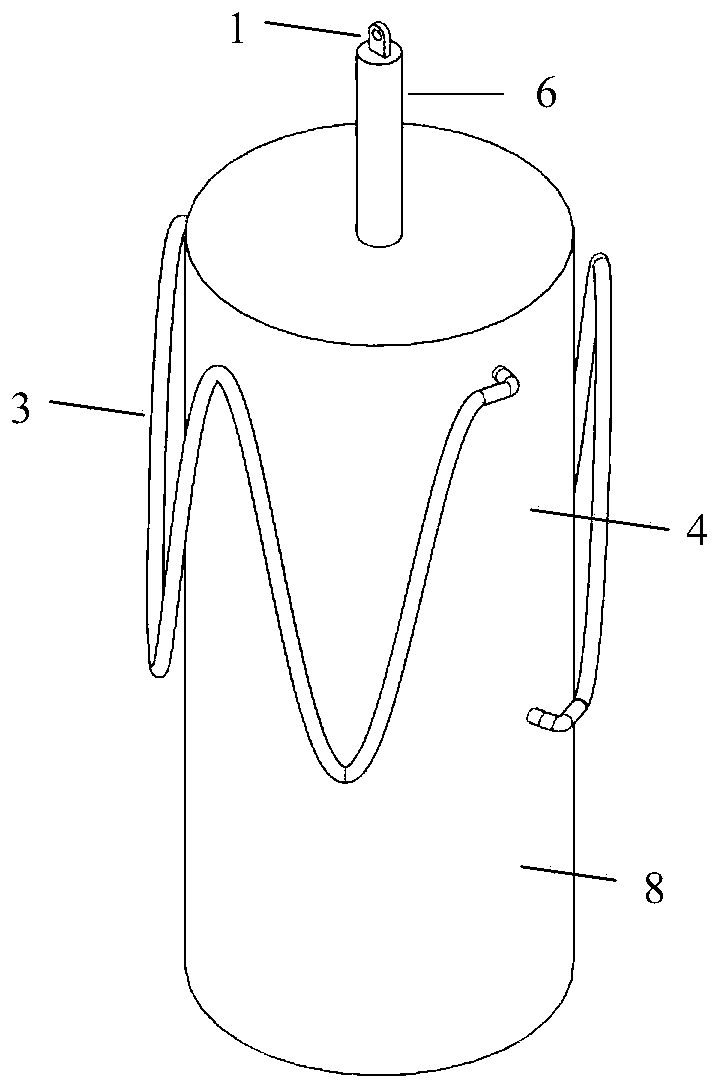

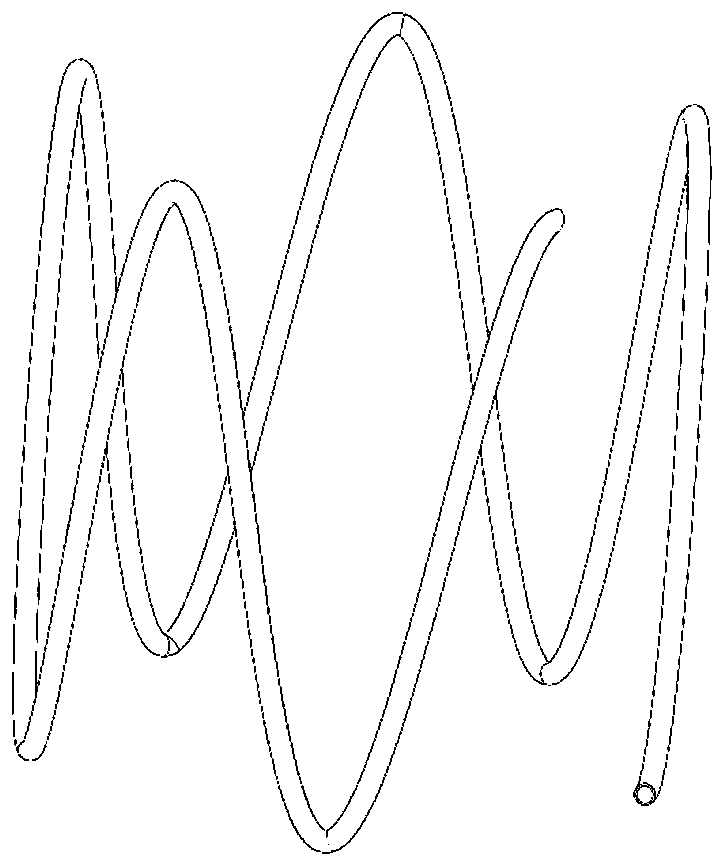

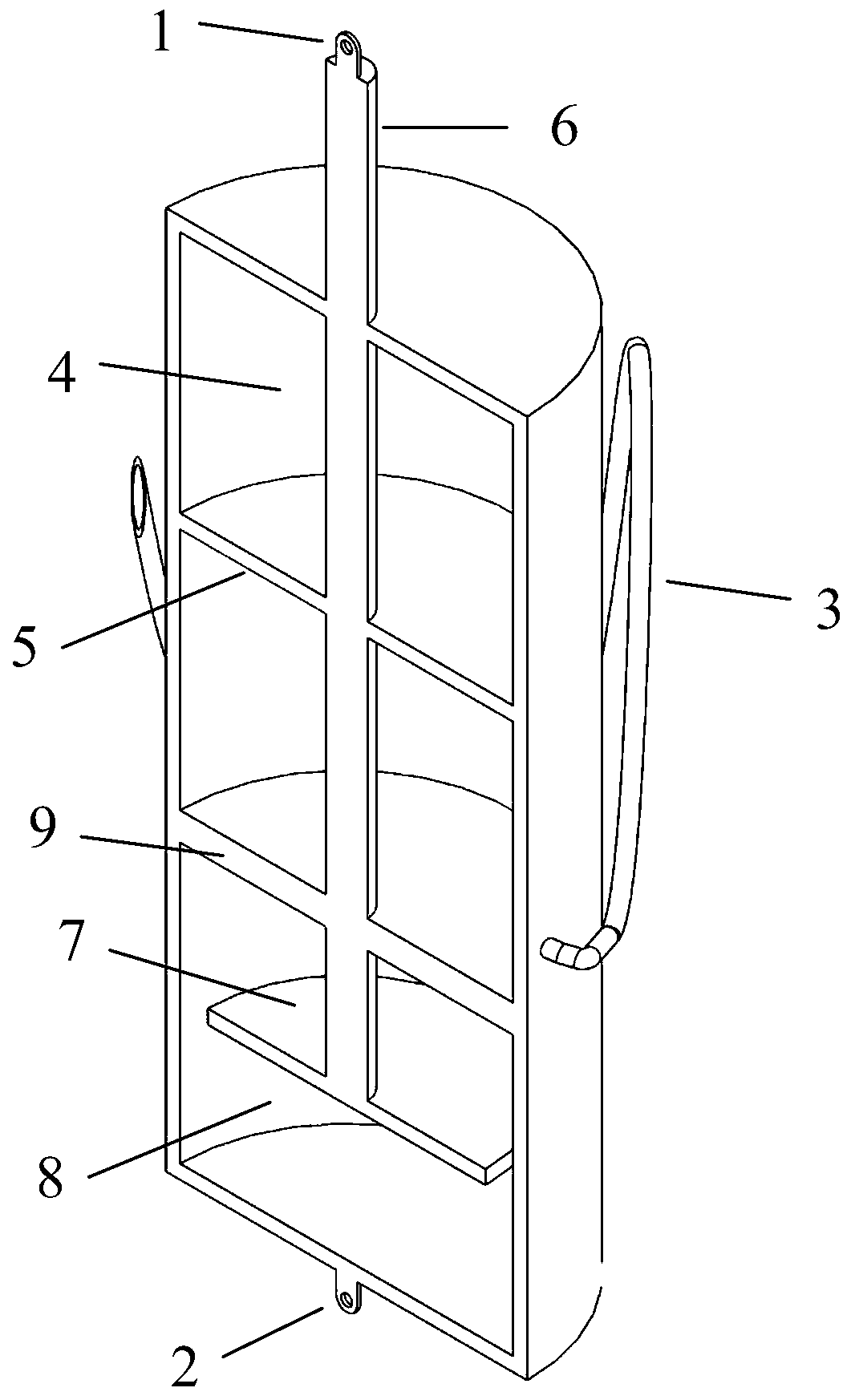

[0023] combine Figure 1 to Figure 3 , the corrugated tube surrounding type gas inertial capacity described in the present invention comprises a cylindrical tank body, a corrugated pipeline 3, a piston 5, a piston rod 6, a baffle plate 7 and a horizontal partition 9, and the cylindrical tank body is provided with The horizontal partition 9, the horizontal partition 9 divides the cylindrical tank into two independent and disconnected cavities, the upper cavity is the cylinder 4, the lower cavity is the stroke chamber 8, and the piston 5 is fixed on the piston On the rod 6, the baffle plate 7 is fixed on the bottom surface of the piston rod 6, the center of the baffle plate 7 is provided with a circular hole, the piston rod 6 is arranged in the cylindrical tank body and passes through the circular hole, and the upper end of the piston rod 6 protrudes from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com