A sliding charging joint and charging pile

A charging connector and sliding technology, applied in the field of sliding charging connectors, can solve problems such as hidden safety hazards, dust and insect short circuits, and achieve the effect of expanding the use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

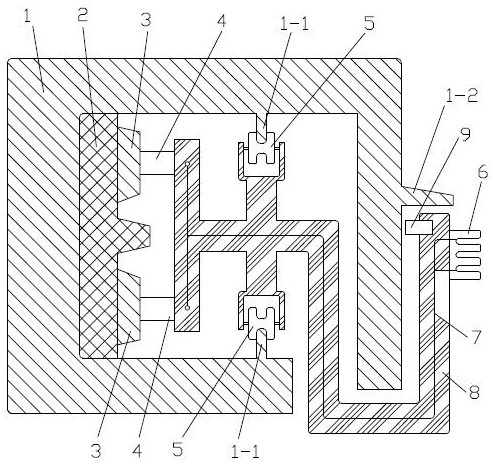

[0012] attached figure 1 It is a schematic structural diagram of the first embodiment of the sliding charging connector of the present invention. The sliding charging connector in the illustration includes a frame-shaped shell 1 with a gap left in the cross section, a socket bracket 8, a charging socket 6 and a pair of conductive metal tracks 3. The notch is arranged on the lower side of the casing 1 to prevent dust from entering and electric shock accidents. The pair of conductive metal rails 3 are fixedly installed in the casing 1 along the length direction of the casing 1. An insulating gasket 2 is arranged between the contact side of the conductive metal rail 3 and the casing 1. There is a limit guide rail 1-1 parallel to the conductive metal track 3, and the socket bracket 8 is slidably connected with the limit guide rail 1-1 through a pair of pulleys 5 corresponding to the position limit guide rail 1-1 on it, and is fixedly installed on the The middle part of the pulley...

Embodiment 2

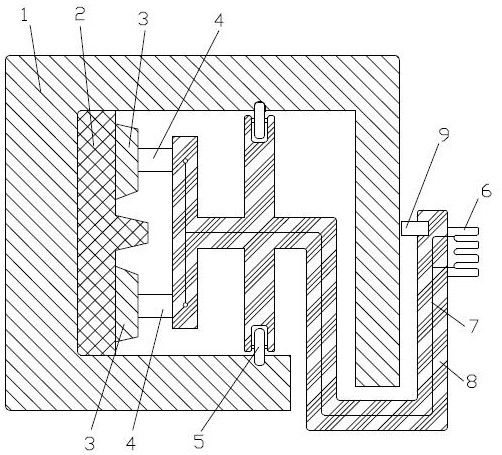

[0015] attached figure 2 It is a schematic structural diagram of the second embodiment of the sliding charging joint of the present invention, which is basically the same as the first embodiment. The difference is that the limit track is an inner groove type, and the embedded pulley 5 can slide in the limit track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com