Construction method of laser resonator with large folding angle

A technology of laser resonator and construction method, which is applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems such as complexity, affecting the use of optical components, and resonant cavities beyond the stable zone, so as to achieve simple design, simple structure, The effect of shortening the cavity length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and embodiments.

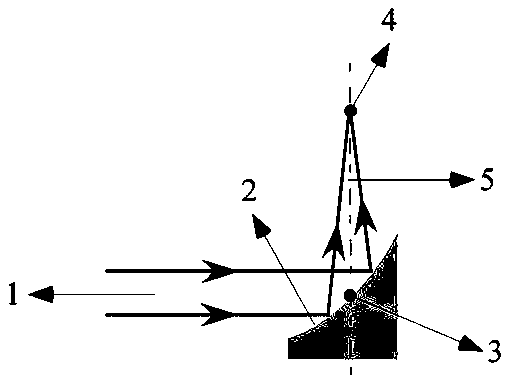

[0017] The design principle of the present invention is to separate any curved surface at the non-central axis of the rotationally symmetrical paraboloid as a reflection surface, thereby realizing the separation of the incident beam and the focused beam.

[0018] see figure 1 , a method for constructing a laser resonant cavity with a large folding angle provided by the present invention is to set an off-axis parabolic mirror in the cavity, the parallel light beam 1 is incident on the off-axis parabolic mirror 2, and is reflected and focused by the off-axis parabolic mirror 2, and the incident light The distance from the center 3 to the focal point 4 is the reflective focal length, and the angle between the incident light and the reflected light 5 is called the off-axis angle, which can be selected from 90º to 180º.

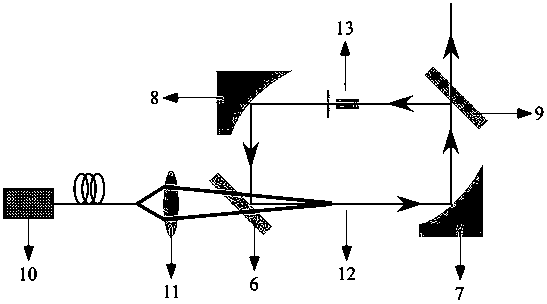

[0019] see figure 2 , what the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com