Novel high-efficiency rice filling device for processing lotus roots filled with glutinous rice

A new type of technology for glutinous rice lotus, applied in the field of new high-efficiency rice irrigation devices for glutinous rice lotus, can solve the problems of not being able to meet the efficiency requirements of mass production of glutinous rice lotus and low overall efficiency, and achieve improved rice irrigation efficiency, stability, and mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

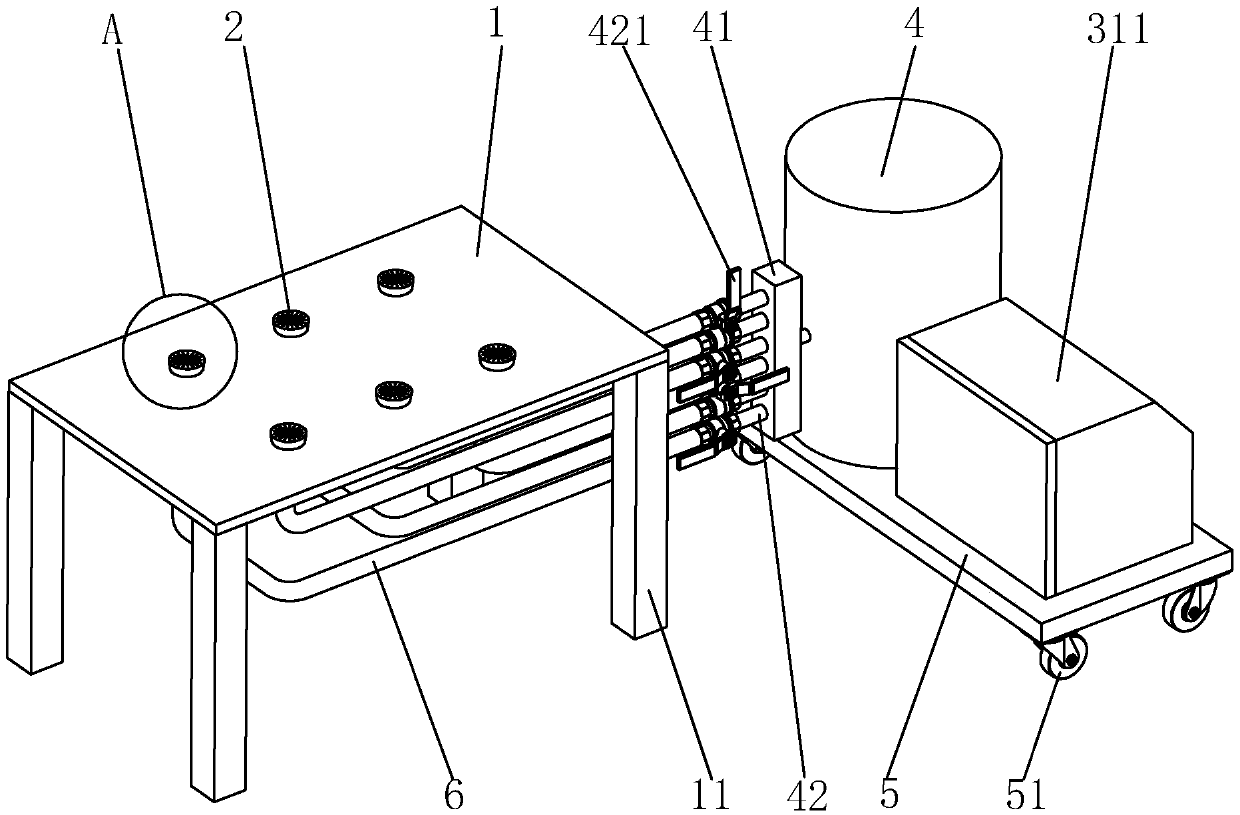

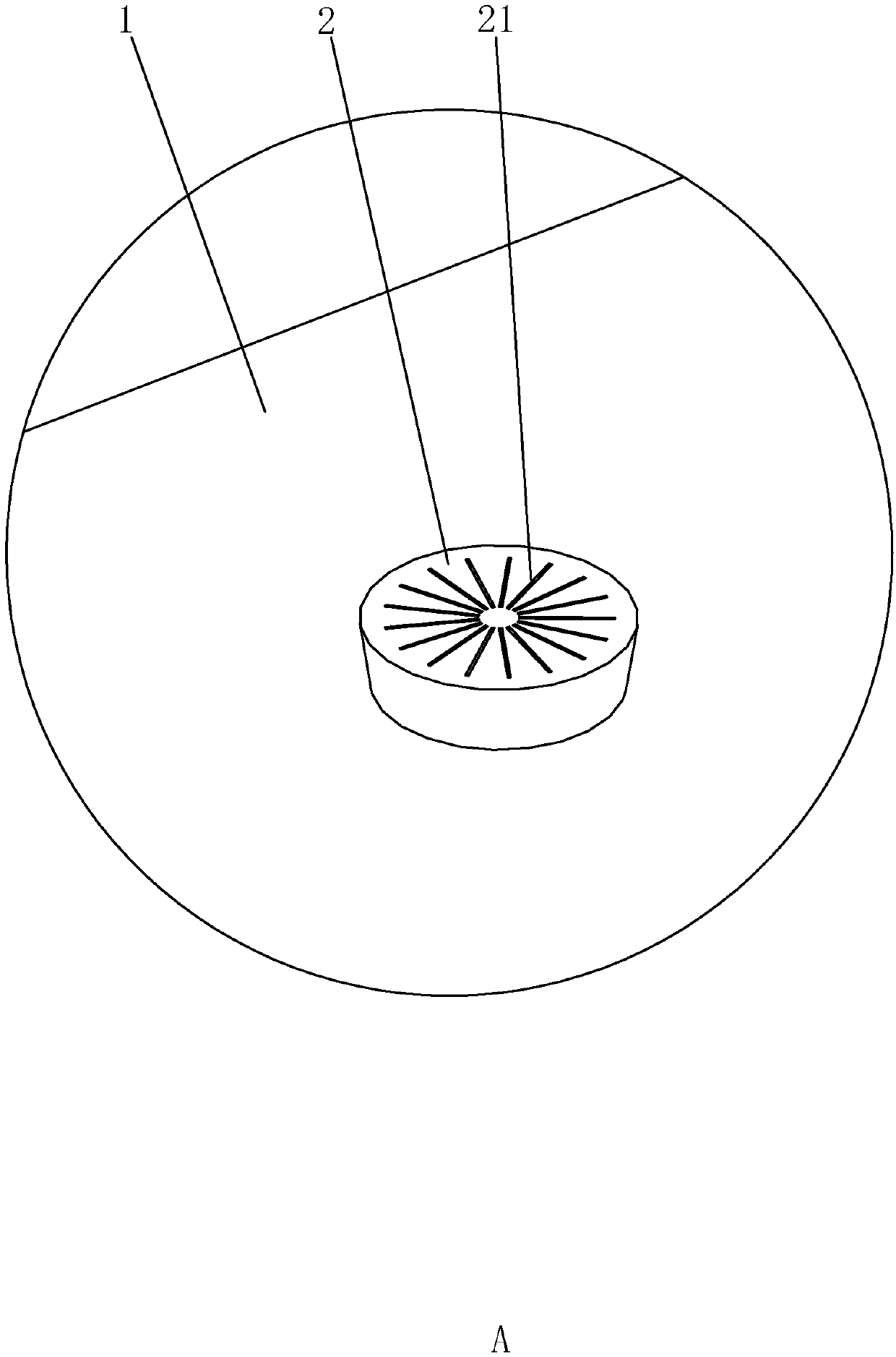

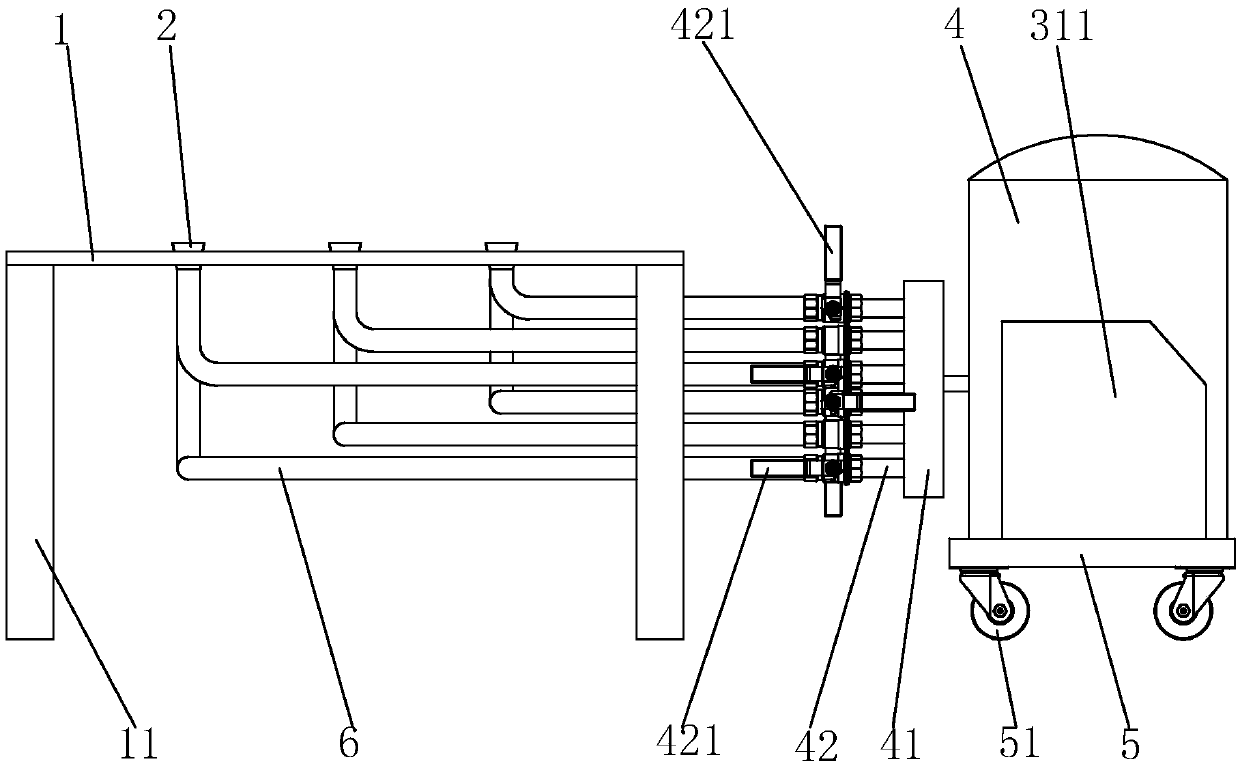

[0041] A new high-efficiency rice filling device for glutinous rice and lotus root, such as figure 1 As shown, including workbench 1, workbench 1 is provided with hollow boss 2, the top surface of boss 2 is provided with ventilation groove 21, and the bottom of boss 2 is connected with exhaust device 3 (refer to Figure 4 ), an air storage tank 4 is connected between the exhaust device 3 and the boss 2 .

[0042] The workbench 1 is a cuboid plate structure arranged horizontally, the bottom is fixedly connected with a support 11, and the support 11 stands on the ground. One side of the bracket 11 is provided with a carrier 5 , which is a horizontally arranged plate structure, and a plurality of wheels 51 are arranged at the bottom of the carrier 5 . combine Figure 4 , the top of the carrier 5 is provided with an exhaust device 3, and the exhaust device 3 selects a vacuum pump 31 or a vacuum pump 31 connected with a cooling fan 32 ( Figure 4 Shown in is the vacuum pump 31 t...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] Such as Figure 5-7 As shown, each boss 2 is correspondingly provided with a photoelectric switch 12 for controlling the opening and closing of the corresponding wind control switch 421 , and the through-beam photoelectric switch 12 can be selected. The through-beam photoelectric switch 12 includes a transmitter and a receiver, both of which are fixedly arranged on the top surface of the workbench 1 and respectively arranged on both sides of the corresponding boss 2 along the width direction of the workbench 1 . The light beam of the through-beam photoelectric switch 12 is in a horizontal state and passes directly above the boss 2, and the height to the top surface of the boss 2 is lower than that of the coupling.

[0050] The use process of this embodiment is as follows:

[0051] Turn on the vacuum pump 31, place the lotus root with its pedicle removed at both ends vertically on the boss 2, the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com