Dispersion and filtering all-in-one machine used for anticorrosive paint production

An anti-corrosion coating and integrated machine technology, applied in grain processing and other directions, can solve problems such as waste of raw materials, low work efficiency, and inability to screen anti-corrosion coatings, and achieve the effects of improving filtration efficiency, improving production efficiency, and enhancing filtration quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

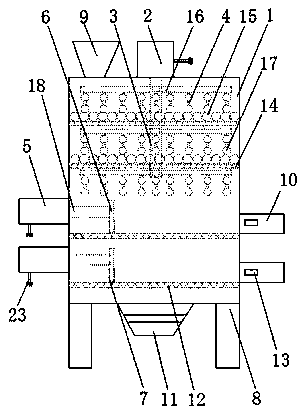

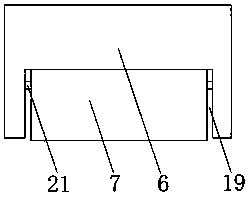

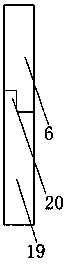

[0022] as attached Figure 1-4 As shown, a kind of anti-corrosion coating production uses the dispersing filtration all-in-one machine, comprises dispersing barrel 1, motor 2, transmission shaft 3, connecting rod 4, cylinder 5, push plate 6 and limit plate 7, it is characterized in that: described dispersing The barrel 1 is arranged on the support 8, the top of the dispersion barrel 1 is provided with a feed bin 9, the side wall is provided with a discharge pipe 10, the bottom is provided with a discharge bin 11, and a sieve plate 14 is arranged in the dispersion barrel 1, Described motor 2 is arranged on the dispersion barrel 1 top, and is provided with power line 23 on motor 2, and described transmission shaft 3 is arranged in the dispersion barrel 1, and transmission shaft 3 tops are connected with motor 2, and on transmission shaft 3 is provided with a stirring rod 16, the connecting rod 4 is arranged on the stirring rod 16, and a projection 17 is arranged on the connectin...

Embodiment 2

[0031] as attached Figure 5As shown, a kind of anti-corrosion coating production uses the dispersing filtration all-in-one machine, comprises dispersing barrel 1, motor 2, transmission shaft 3, connecting rod 4, cylinder 5, push plate 6 and limit plate 7, it is characterized in that: described dispersing The barrel 1 is arranged on the support 8, the top of the dispersion barrel 1 is provided with a feed bin 9, the side wall is provided with a discharge pipe 10, the bottom is provided with a discharge bin 11, and a sieve plate 14 is arranged in the dispersion barrel 1, Described motor 2 is arranged on the dispersion barrel 1 top, and is provided with power line 23 on motor 2, and described transmission shaft 3 is arranged in the dispersion barrel 1, and transmission shaft 3 tops are connected with motor 2, and on transmission shaft 3 is provided with a stirring rod 16, the connecting rod 4 is arranged on the stirring rod 16, and a projection 17 is arranged on the connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com