An integrated stove switch quality detection device

A detection device and technology for integrated stoves, which are applied in the field of integrated stoves and can solve the problems of poor quality of switches of integrated stoves, affecting use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

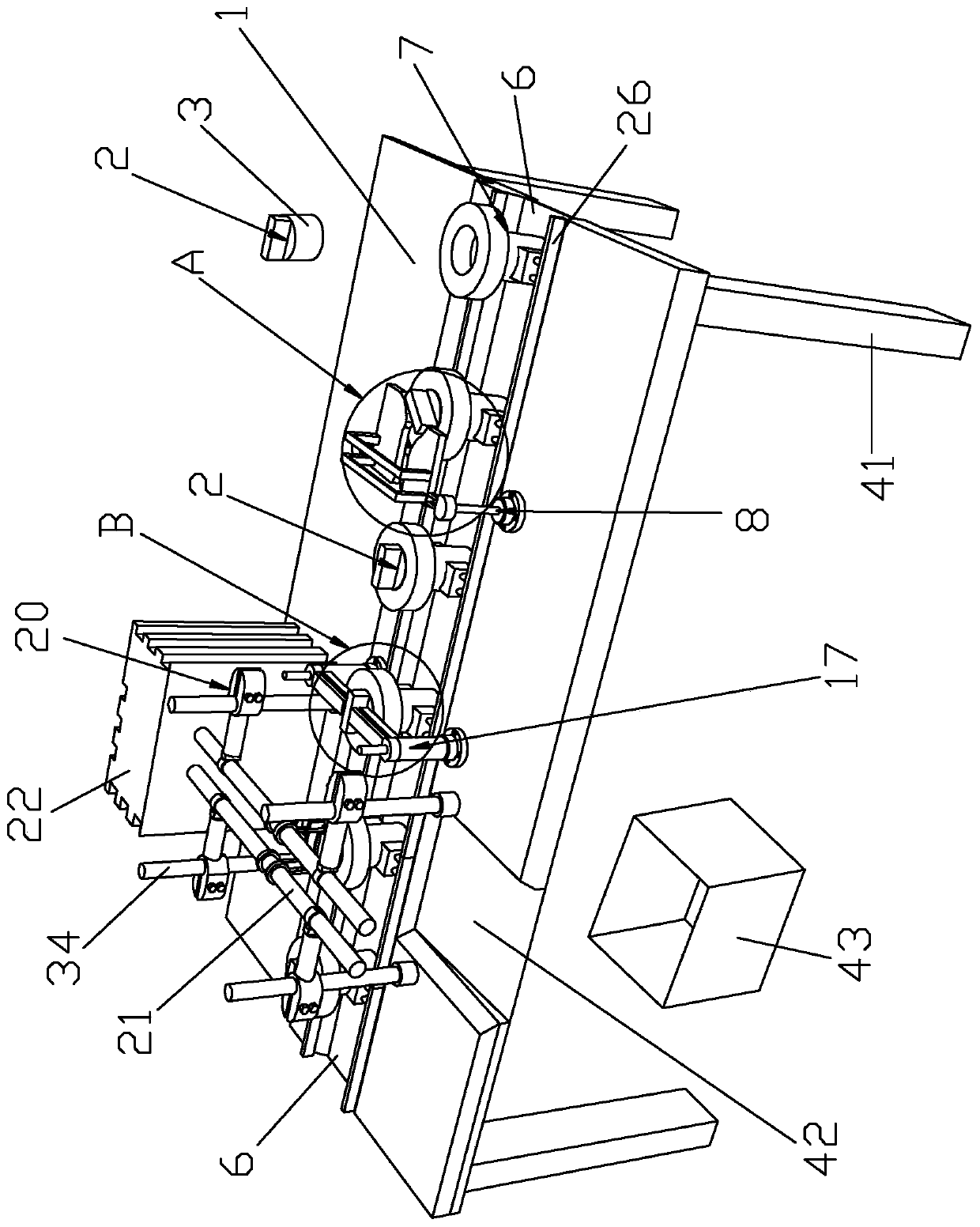

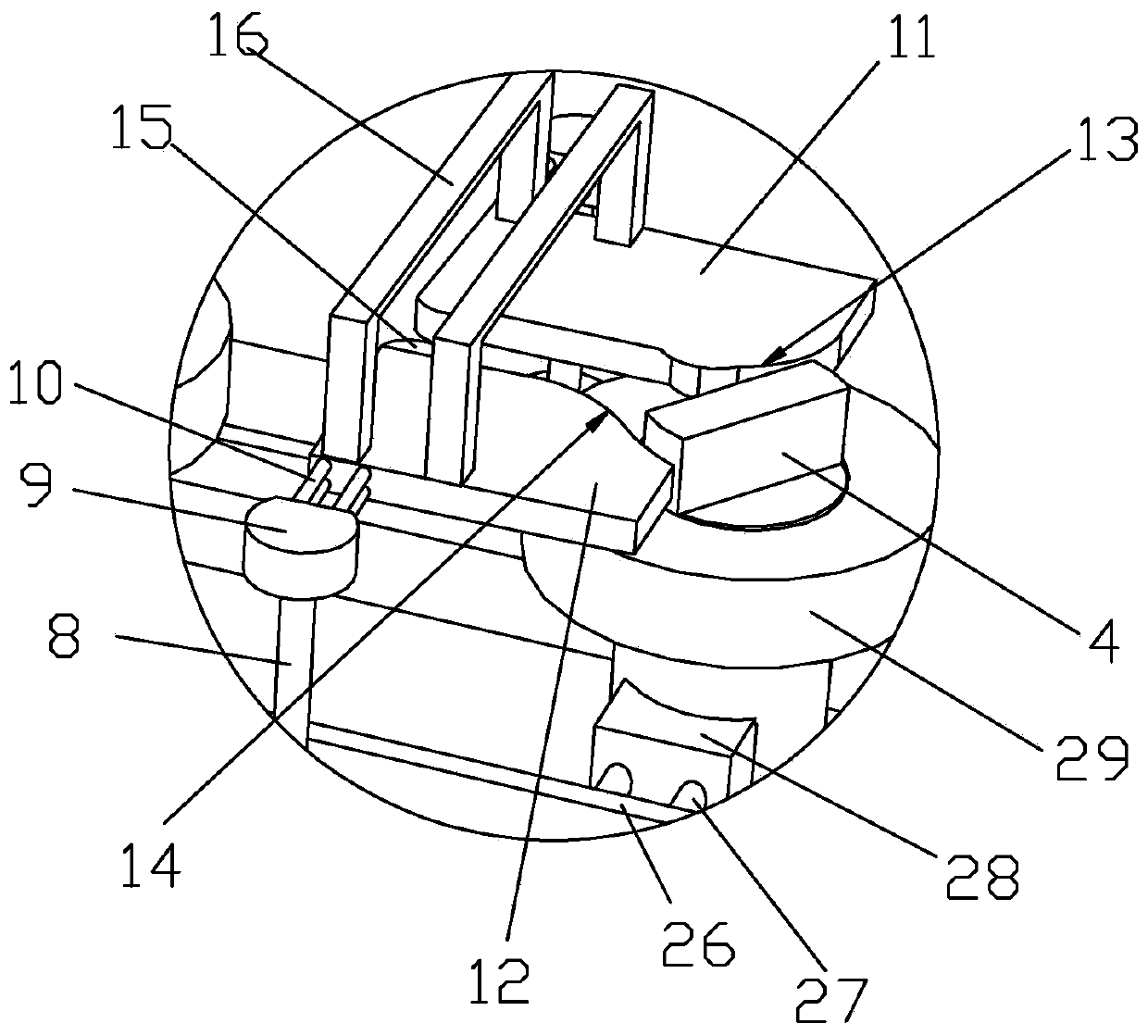

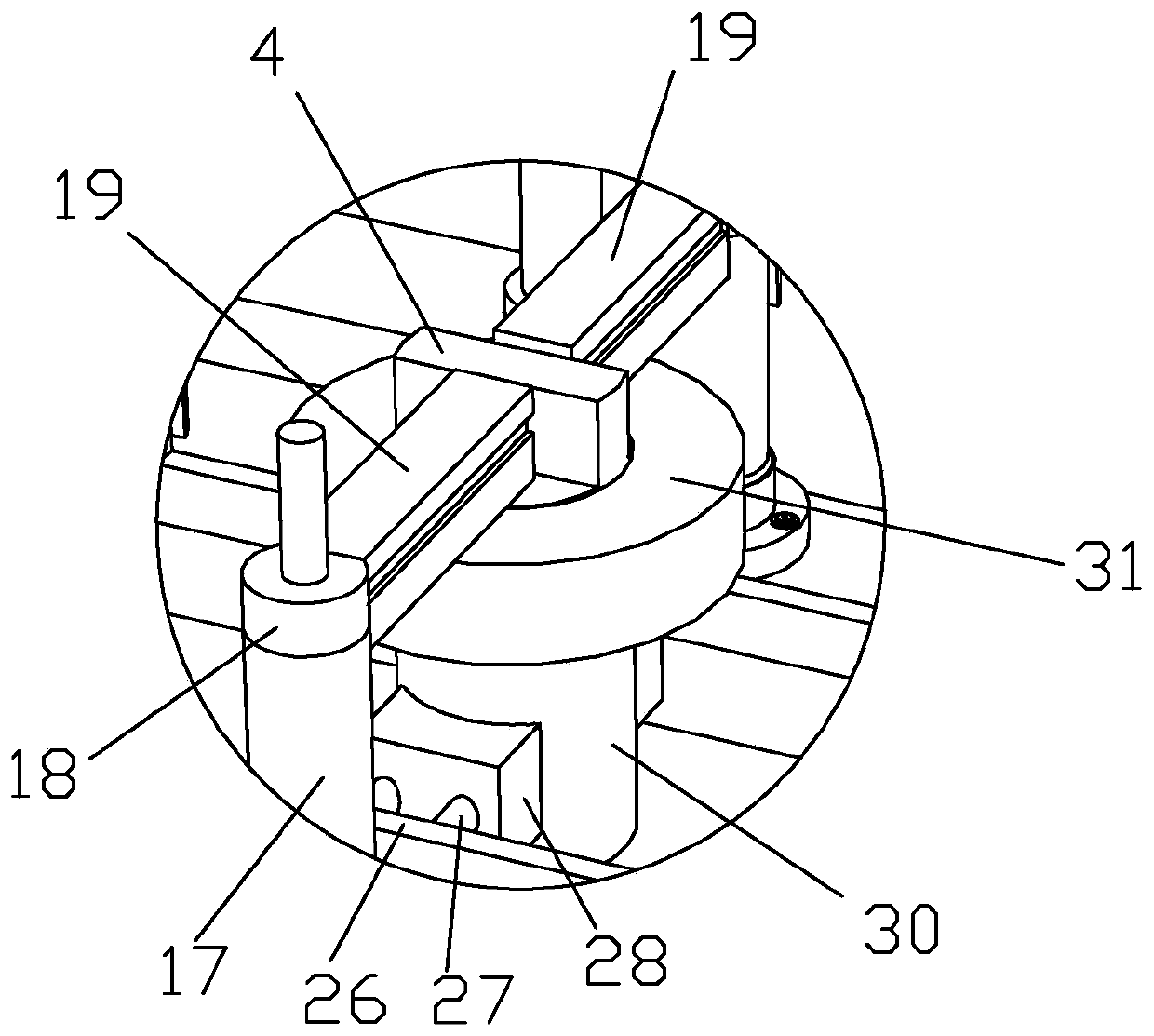

[0028] Such as Figure 1 to Figure 7 As shown in , it is a quality detection device for an integrated cooker switch of the present invention, which includes a workbench 1 and a switch to be tested 2. Roller 5, roller 5 is evenly arranged, and the top of roller 5 is provided with conveyor belt 6, and conveyor belt 6 is evenly provided with conveyer 7, and conveyer 7 is connected with switch 2 to be detected, has made things convenient for the operation of conveyer 7, to conveyer Place the switch 2 to be detected in 7, if it cannot be put in normally, it means that there is a size difference in the fixed seat 3 of the switch to be detected, and it is a defective product, so it should be placed separately. to run. Workbench 1 is provided with connecting frame 8, and connecting frame 8 is provided with fixed head 9, and fixed head 9 is evenly provided with fixed bar 10, and fixed bar 10 is provided with first adjusting plate 11 and second adjusting plate 12, and first adjusting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com