Shell mounting equipment for production of electric appliance instrument

A technology for installing equipment and casings, which is applied in the direction of electrical equipment shells/cabinets/drawers, metal processing equipment, electrical components, etc., and can solve the problems of difficulty in adapting to the mass production of electrical instruments, low accuracy of manual installation, and heavy workload and other issues to achieve the effect of saving manpower, balancing strength and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

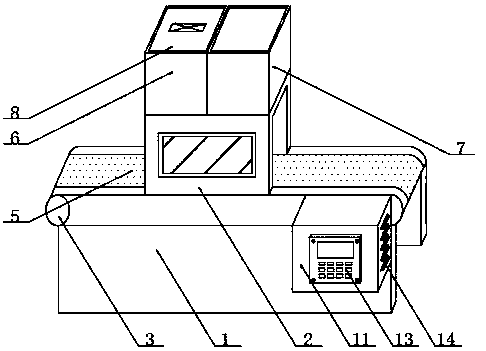

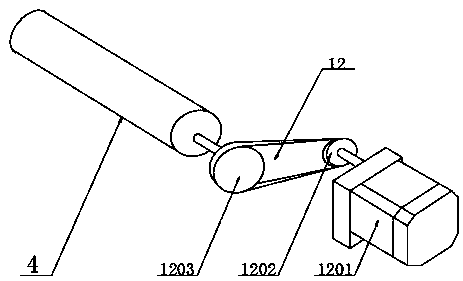

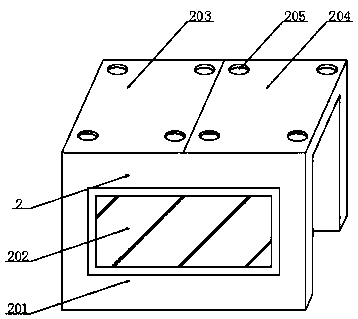

[0023] see Figure 1~5 , in an embodiment of the present invention, a shell installation device for the production of electrical instruments, comprising a fixing seat 1, the upper surface of the fixing seat 1 is fixedly equipped with a working compartment 2, and the upper surface of the fixing seat 1 is close to the working compartment 2 The inner side of the drive box 11 is fixedly equipped with a conveyor belt 5, the front surface of the fixed base 1 is fixedly installed with a drive box 11, the inside of the drive box 11 is fixedly installed with a drive device 12, and the front surface of the drive box 11 is embedded with a control switch. 13. The side of the driving box 11 is provided with an air vent 14 for ventilation. The driving device 12 includes a stepping motor 1201. The rotating end of the stepping motor 1201 is fixedly connected with a driving wheel 1202. The driving wheel 1202 A driven wheel 1203 is rotatably connected to the side of the drive wheel 1202, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com