A method for suspending a motor by an axially precompressed combined elastic element

An elastic element and pre-compression technology is used in the field of suspending vehicle motors by combining elastic elements with axial pre-compression. The effect of increasing the axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

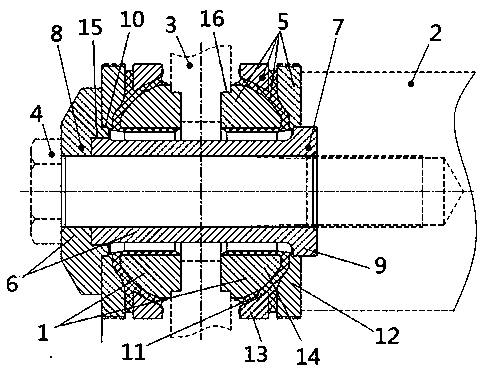

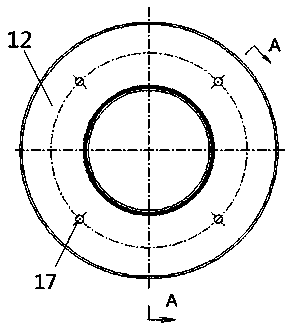

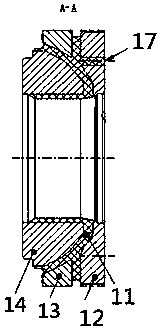

[0036] It can be seen from the accompanying drawings that the present invention relates to a method for hanging a motor by axially precompressing a combined elastic element, and suspending the motor of the vehicle on the bogie of the vehicle through an elastic composite elastic element; it is characterized in that: The elastic composite elastic element described above is an axial precompression combined elastic part 1, the vehicle motor 2 is suspended on the bogie beam mounting seat 3 by the axial precompression combined elastic part 1, and the axial precompression combined elastic part passes through the fastener 4 is connected with the vehicle motor 2 to form the suspension of the vehicle motor.

[0037] The axial precompression combined elastic member 1 is composed of two elastic elements 5, and the two elastic elements 5 are axially precompressed and clamped on the bogie beam mounting seat 3 from both sides of the bogie beam mounting seat 3, and The fasteners 4 are axially...

Embodiment 2

[0048] The principle of the second embodiment is the same as that of the first embodiment, only slightly different in structure. It is a method for hanging a motor through an axially precompressed combined elastic element, in which the vehicle motor is suspended on the bogie of the vehicle through an elastic composite elastic element; it is characterized in that: the elastic composite elastic element is axial The pre-compressed combined elastic part, the vehicle motor is suspended on the bogie by the axial pre-compressed combined elastic part, and the axially pre-compressed combined elastic part is connected with the vehicle motor through fasteners to form the suspension of the vehicle motor.

[0049] The axially precompressed combined elastic member is composed of two elastic elements, and the two elastic elements are axially precompressed and clamped on the bogie from both sides of the bogie, and are combined together by the axial precompression of the fasteners , forming an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com