PA66 composite material and preparation method thereof

A technology of PA66 and composite materials, applied in the field of polymer materials, can solve the problems of insufficient anti-aging properties of PA66, and achieve the effect of improving anti-aging properties, improving anti-aging properties, and increasing the value of promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

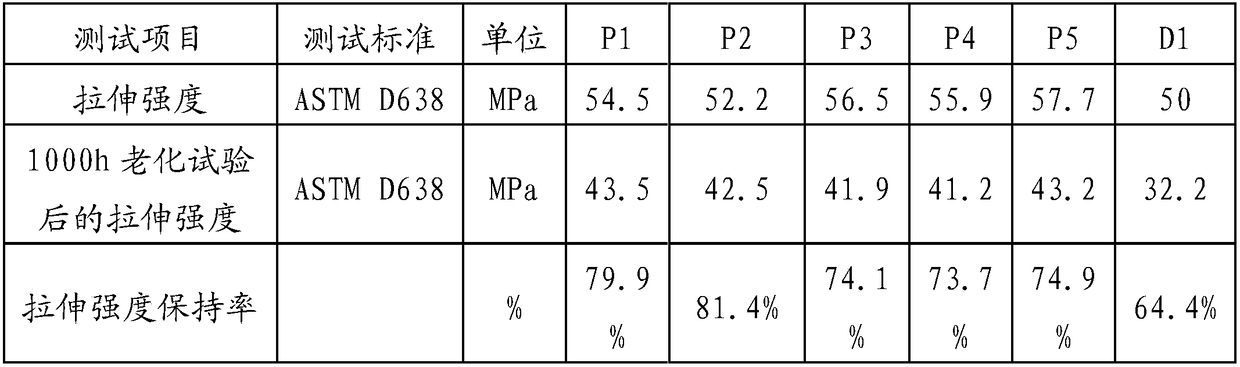

Examples

preparation example Construction

[0035] The preparation steps of anti-aging masterbatch include:

[0036] (1) Weigh a certain amount of nano-TiO2 and silane coupling agent KH550, put the two into a three-necked flask, and react for 30-40min to obtain modified nano-TiO2;

[0037] (2) Weigh a certain amount of PA66 salt, concentrated phosphoric acid, 3,3,4,4-biphenyltetracarboxylic dianhydride, modified nano TiO2 and deionized water;

[0038] (3) PA66 salt, concentrated phosphoric acid, 3,3,4,4-biphenyltetracarboxylic dianhydride and nano-TiO 2 Put it into the reaction kettle, stir evenly, add deionized water, and stir again;

[0039] (4) After sealing the lid of the kettle, start to increase the temperature and pressure. When the temperature in the kettle reaches 220°C and the pressure reaches 2.3MPa, keep the temperature and pressure for 3-5 hours;

[0040] (5) Adjust the pressure and temperature in the kettle, raise the temperature in the kettle to 265° C., reduce the pressure to normal pressure, and keep ...

Embodiment 1

[0051] (1) Weigh 80 parts of PA66, 8 parts of anti-aging masterbatch, 10 parts of POE, 0.1 part of Irganox168 and mix them evenly to obtain a mixture;

[0052] (2) Extrude and granulate the mixture obtained in step (1) to obtain PA66 composite material P1.

[0053] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 200°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 260°C, The head temperature is 260°C; the screw speed is 200r / min.

Embodiment 2

[0055](1) Weigh 100 parts of PA66, 12 parts of anti-aging masterbatch, 16 parts of POE, 0.1 part of Irganox168, 0.2 part of Irganox1330, 0.2 part of Irganox1010 and mix them evenly to obtain a mixture;

[0056] (2) Extrude and granulate the mixture obtained in step (1) to obtain PA66 composite material P2.

[0057] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 220°C, the temperature of the second zone is 280°C, the temperature of the third zone is 280°C, the temperature of the fourth zone is 280°C, the temperature of the fifth zone is 280°C, and the temperature of the sixth zone is 280°C. The head temperature is 280°C; the screw speed is 280r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com