a sucker

A suction cup and disc body technology is applied in the field of washing and sweeping vehicles, which can solve the problems of unclean garbage suction, affecting the effect of garbage suction, affecting the washing effect of washing vehicles, etc., so as to improve the cleaning effect and the cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

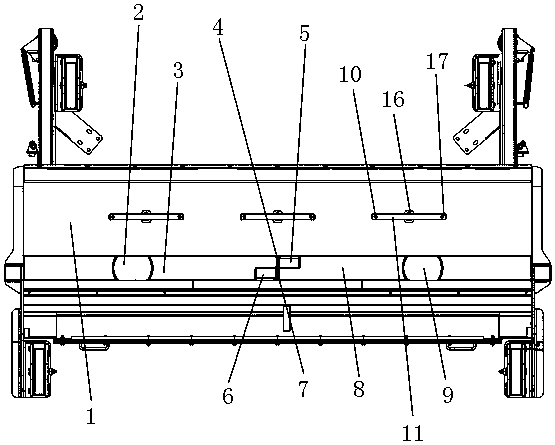

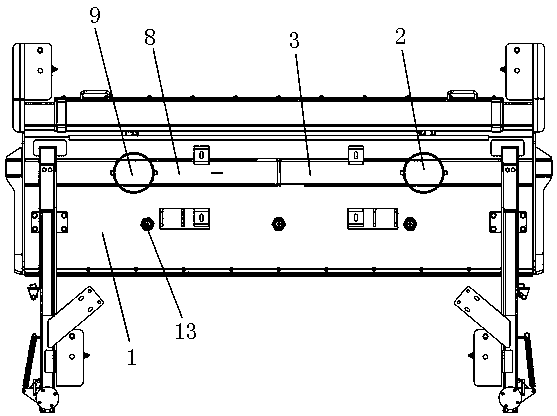

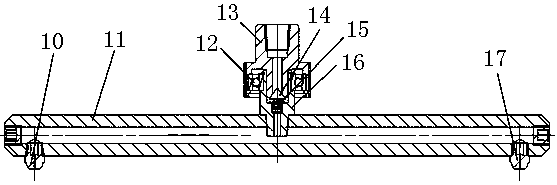

[0013] Figure 1-4 Among them, the present invention discloses a suction cup, which includes a disk body 1, a vacuum chamber, a swing-out high-pressure water spray frame, a high-pressure water spray system and rollers. The dust collection room, the swing-out high-pressure water spray frame, the high-pressure water spray system and the rollers are all arranged on the disc body 1 . The dust chamber is positioned at the middle part of the disk body 1, and the dust chamber includes a left dust chamber and a right dust chamber. The left dust suction chamber comprises a left dust suction hood 3 and a left dust suction pipe 2 , and the left dust suction pipe 2 is arranged on the left dust suction hood 3 . The right dust suction chamber comprises a right dust suction hood 8 and a right dust suction pipe 9, and the right dust suction pipe 9 is arranged on the right dust suction hood 8. The left dust suction cover 3 and the right dust suction cover 8 are respectively located at the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com