Electromagnetic oven with heat dissipation device

A heat dissipation device and induction cooker technology, which is applied in the field of induction cooker, can solve the problems of no discovery, trouble, breakage of the connection between the induction cooker body and the power line, etc., and achieve the effect of reducing loss rate and reducing oil fume pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

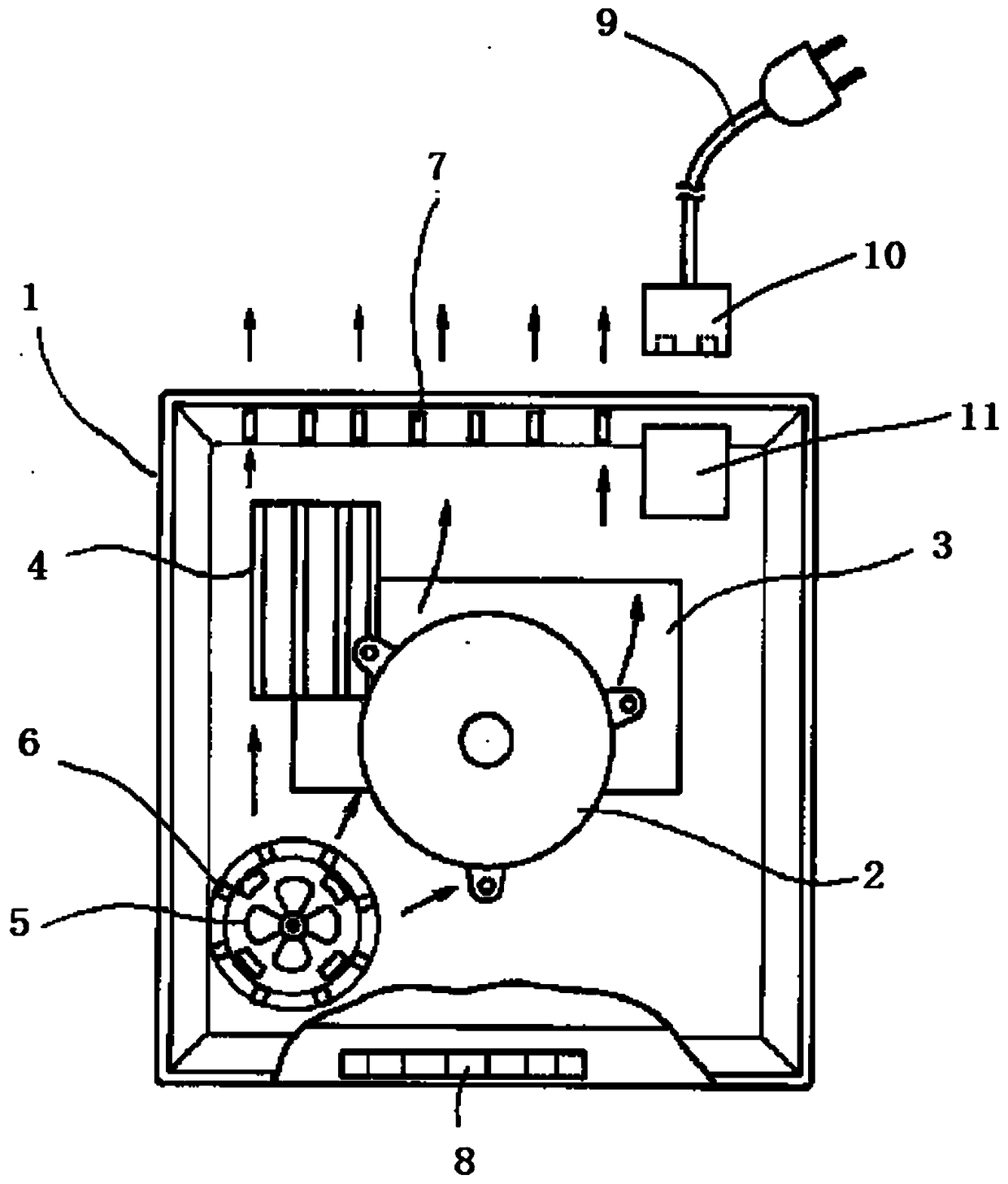

[0023] As shown in the figure, an induction cooker 1 with a heat dissipation device includes a heating element 2, a heating element mounting plate 3, a heat dissipation metal fin plate 4, a main air intake fan 5, a sub-intake module 6, a heat dissipation air outlet 7, and an operation panel 8. Power cord 9, detachable module 10, fixed module 11;

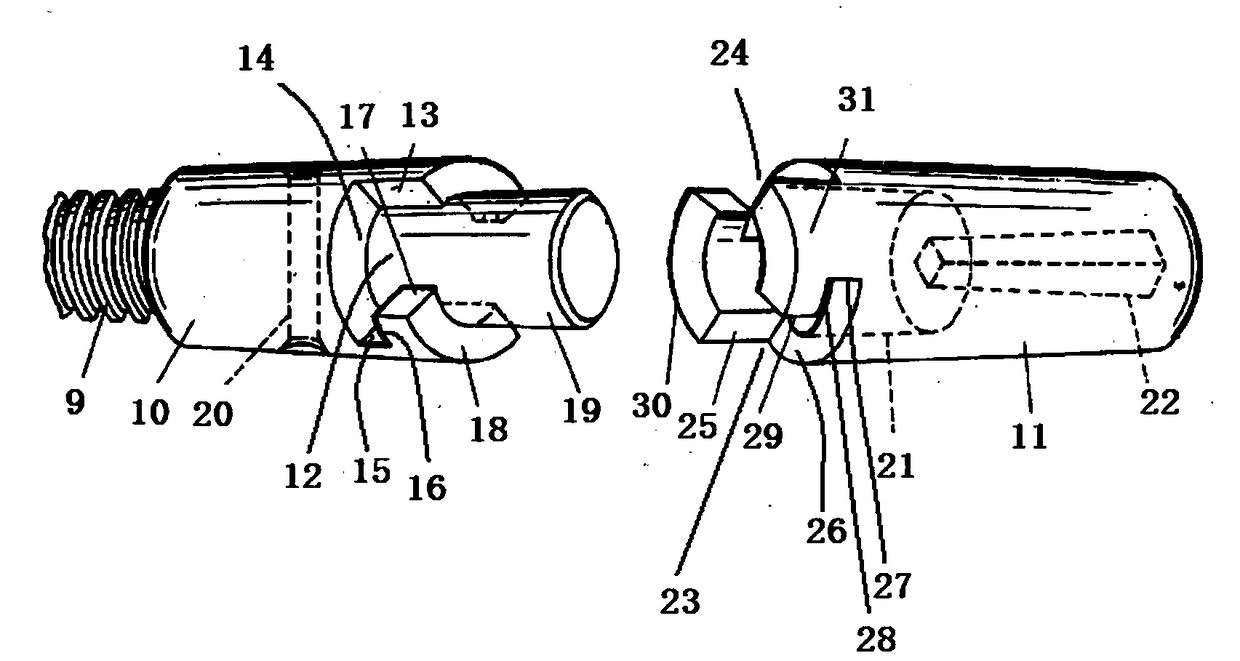

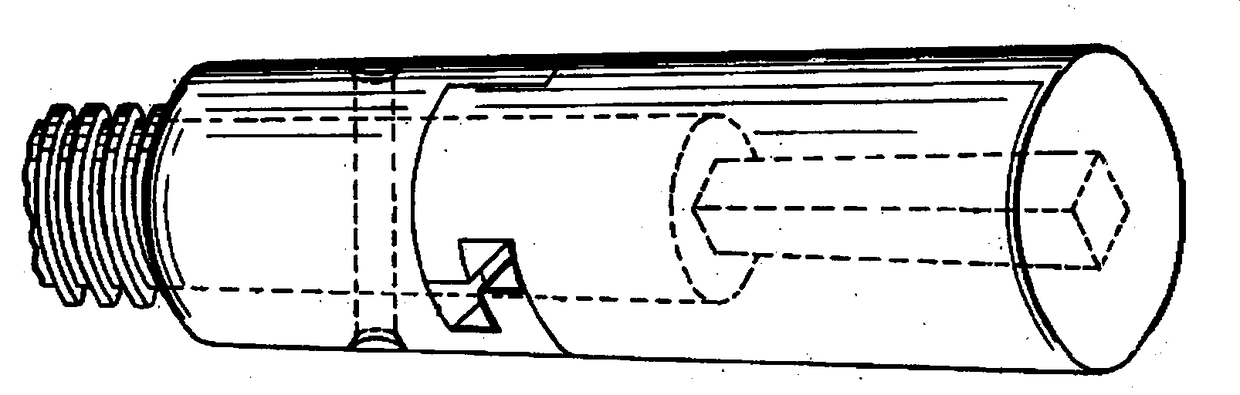

[0024]The detachable module 10 is a hollow cylinder, the left end is connected to the power cord 9, and the right end of the detachable module 10 is provided with a first groove 12 and a second groove along the circumferential direction (not shown in the figure, but the technical field The skilled person can understand), described first groove 12 has first groove first horizontal surface 13, first groove first vertical surface 14, first groove second horizontal surface 15, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com