Food material processing method based on intelligent kitchen system and intelligent kitchen system

A technology of smart kitchen and processing method, applied in the field of smart kitchen to achieve the effect of improving efficiency, reducing energy consumption and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

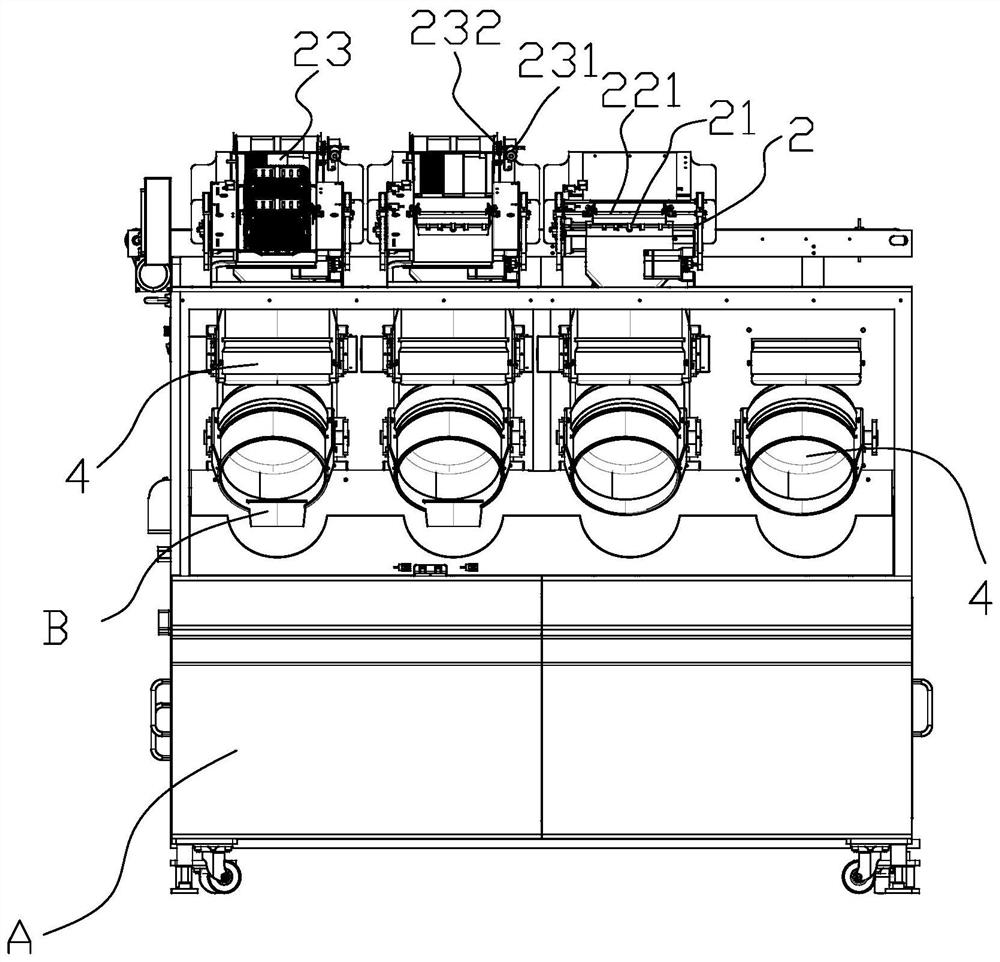

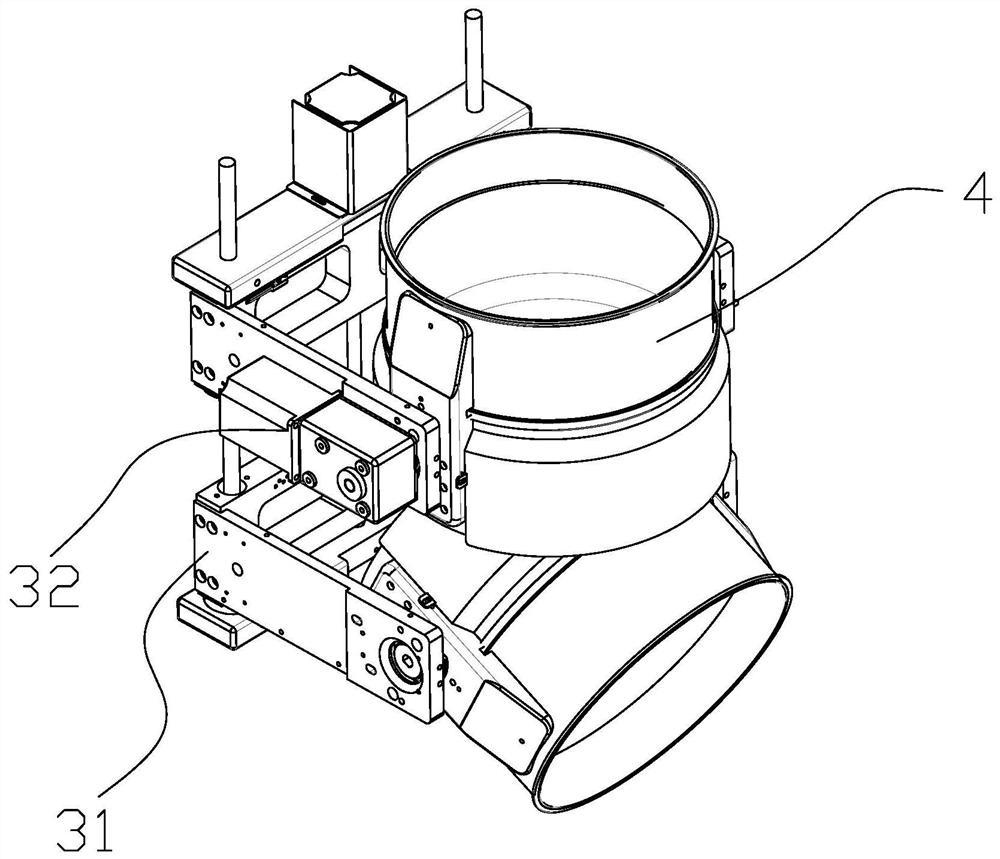

[0114] Embodiment 1 of the present invention provides a food processing method based on a smart kitchen system. In an application scenario, the food processing method can be applied to such as Figure 1-Figure 22In the shown intelligent kitchen system, the intelligent kitchen system may include but not limited to, for example, a pot cover plate 1, a tear film feeding mechanism 2, an auxiliary material supply mechanism (not shown in the figure), a lifting and rotating mechanism 3, a heating pot Mechanism 4, stirring mechanism 5, oil fume processing device 6, refrigerator 7, food material transmission device 8, food box recovery mechanism 9, lunch box separation mechanism 10a, lunch box cover separation mechanism 10b, lunch box moving mechanism 11, capping mechanism 12, The coding mechanism 13 or the food waste crushing mechanism 15, etc. It should be noted that each mechanism involved in the smart kitchen system can be controlled by a control device (not shown in the figure), fo...

Embodiment 2

[0162] Embodiment 2 of the present invention provides an intelligent kitchen system, which can be applied in environments including but not limited to, for example, catering industry or personal family.

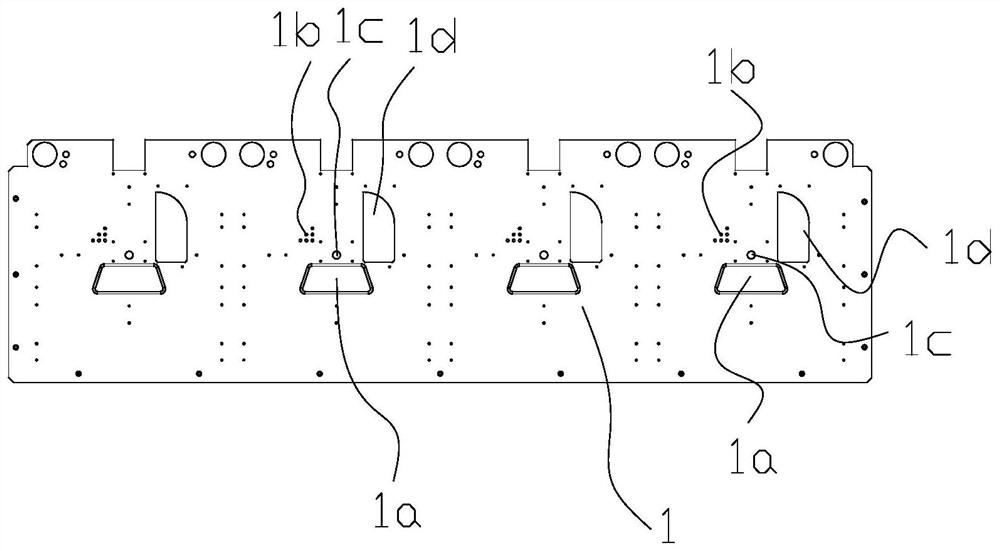

[0163] In one embodiment, such as Figure 1-Figure 22 As shown, the intelligent kitchen system can include a kitchen main frame A, a pot cover plate 1 installed on the kitchen main frame A, a tear film feeding mechanism 2, an auxiliary material supply mechanism (not shown in the figure), a lifting and rotating mechanism 3, Heating pot mechanism 4, stirring mechanism 5 and oil fume processing device 6; specifically, the pot cover plate 1 is provided with food material port 1a, auxiliary material port 1b, stirring mechanism installation hole 1c and oil fume collecting port 1d; tearing film feeding mechanism 2 is provided Above the food material port 1a, the tear film feeding mechanism 2 is used to tear the film of the food material box B so that the food material falls into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com