Hole depth detection device and method

A detection device and detection method technology, applied in the direction of mechanical depth measurement and other directions, can solve the problems of time-consuming and labor-intensive, inaccurate, time-consuming and labor-intensive, and increase the difficulty of construction for inspection personnel, and achieve the effect of improving the work efficiency of workers, being convenient to carry, and saving inspection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

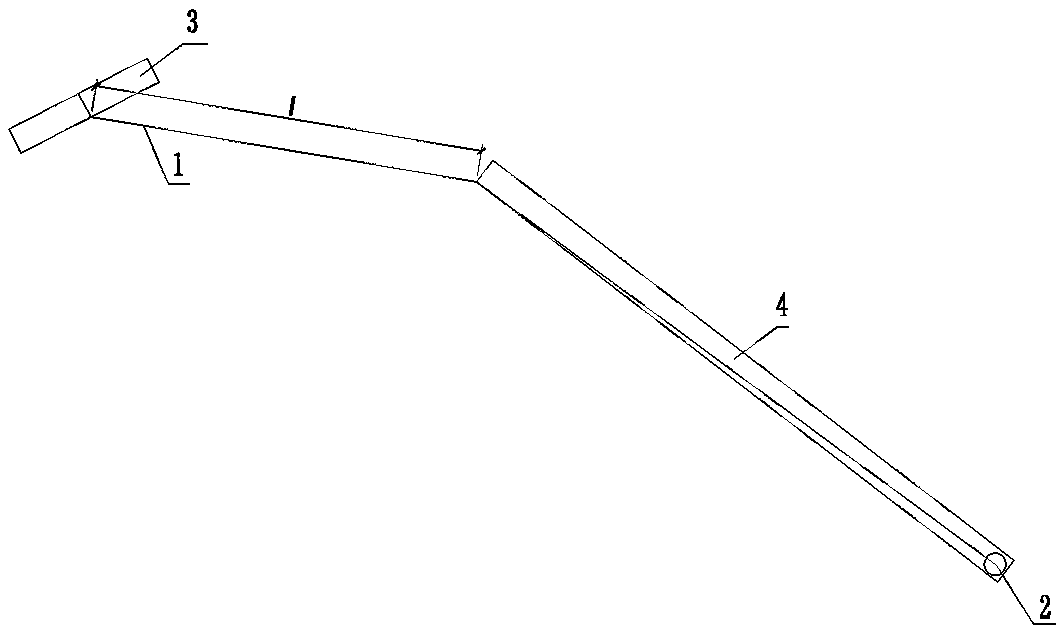

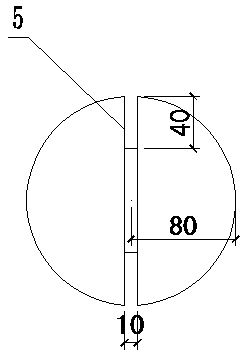

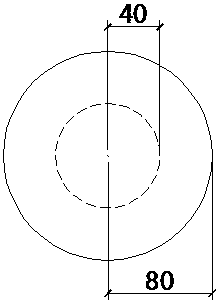

[0025] see figure 1 , one Seed hole depth detection device, including a fixed length L Dalima line 1, a bamboo ruler 3, and a shot put 2, the diameter of the Dalima line 1 is 0.3mm, the length of the bamboo ruler 3 is 80mm, the width is 20mm, and the diameter of the shot put 2 80mm, an annular groove 5 is cut on the shot 2 by a cutting machine, and the annular groove 5 is 10mm wide and 40mm deep. One end is wrapped around the annular groove 5 of the lead ball 2 and fixedly stuck.

[0026] The detection method of the above-mentioned hole depth detection device comprises the following steps:

[0027] (1) Divide the measurement areas into groups according to the site conditions, with 15-20 points in each group.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com