Determination method for densification strain of cushion packaging material

A technology of buffer packaging and determination method, which is applied in the direction of analyzing materials, using stable tension/pressure testing material strength, measuring devices, etc. Changes in strain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Determine a kind of method of regular hexagonal honeycomb paperboard densification strain, its specific steps are as follows:

[0061] Step 1. First, carry out constant temperature and humidity pretreatment on the material, set the temperature to 23°C, set the humidity to 65%, measure the thickness of the material to 40mm, and then use the universal material testing machine to conduct a static compression test on the material. According to the test Draw force-displacement curves as a result;

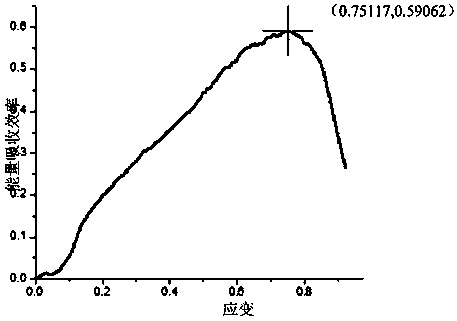

[0062] Step 2, convert the force-displacement curve of step 1 to obtain the stress-strain curve (see figure 2 ), the calculation formula of stress and strain is as follows:

[0063] σ=F / A×10 6

[0064] ε=X / T

[0065] In the formula, σ is the compressive stress, the unit is Pa; P is the compressive load, the unit is N; A is the bearing area of the test sample, the unit is mm 2 .

[0066] ε is the compressive strain; X is the deformation, in mm; T is the original thickness ...

Embodiment 2

[0076] Determine a kind of method of C-type corrugated cardboard densification strain, its specific steps are as follows:

[0077] Step 1: First, carry out constant temperature and humidity pretreatment on the material, set the temperature to 23°C, set the humidity to 65%, measure the thickness of the material to be 25mm, and then use the universal material testing machine to conduct a static compression test on the material, according to the test Draw force-displacement curves as a result;

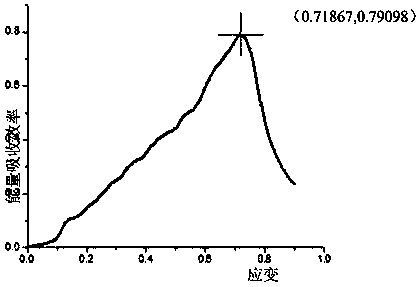

[0078] Step 2, convert the force-displacement curve of step 1 to obtain the stress-strain curve (see Figure 4 ), the calculation formula of stress and strain is as follows:

[0079] σ=F / A×10 6

[0080] ε=X / T

[0081] In the formula, σ is the compressive stress, the unit is Pa; P is the compressive load, the unit is N; A is the bearing area of the test sample, the unit is mm 2 .

[0082] ε is the compressive strain; X is the deformation, in mm; T is the original thickness of the t...

Embodiment 3

[0092] Determine a kind of method of BC type corrugated cardboard densification strain, its specific steps are as follows:

[0093] Step 1: First, carry out constant temperature and humidity pretreatment on the material, set the temperature to 23°C, set the humidity to 65%, measure the thickness of the material to be 28mm, and then use the universal material testing machine to conduct a static compression test on the material, according to the test As a result, force-displacement curves are plotted,

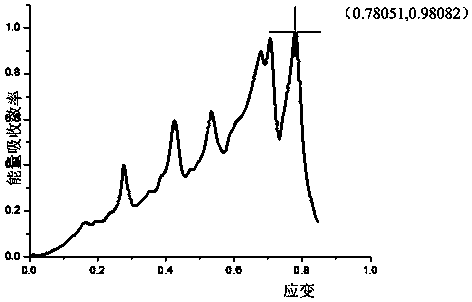

[0094] Step 2, convert the force-displacement curve of step 1 to obtain the stress-strain curve (see Image 6 ), the calculation formula of stress and strain is as follows:

[0095] σ=F / A×10 6

[0096] ε=X / T

[0097] In the formula, σ is the compressive stress, the unit is Pa; P is the compressive load, the unit is N; A is the bearing area of the test sample, the unit is mm 2 .

[0098] ε is the compressive strain; X is the deformation, in mm; T is the original thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com