Test method and test equipment for circuit breaker

A technology for testing equipment and circuit breakers, which can be used in circuit breaker testing, instruments, measuring electricity, etc., and can solve the problems of low test efficiency, occupation, and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

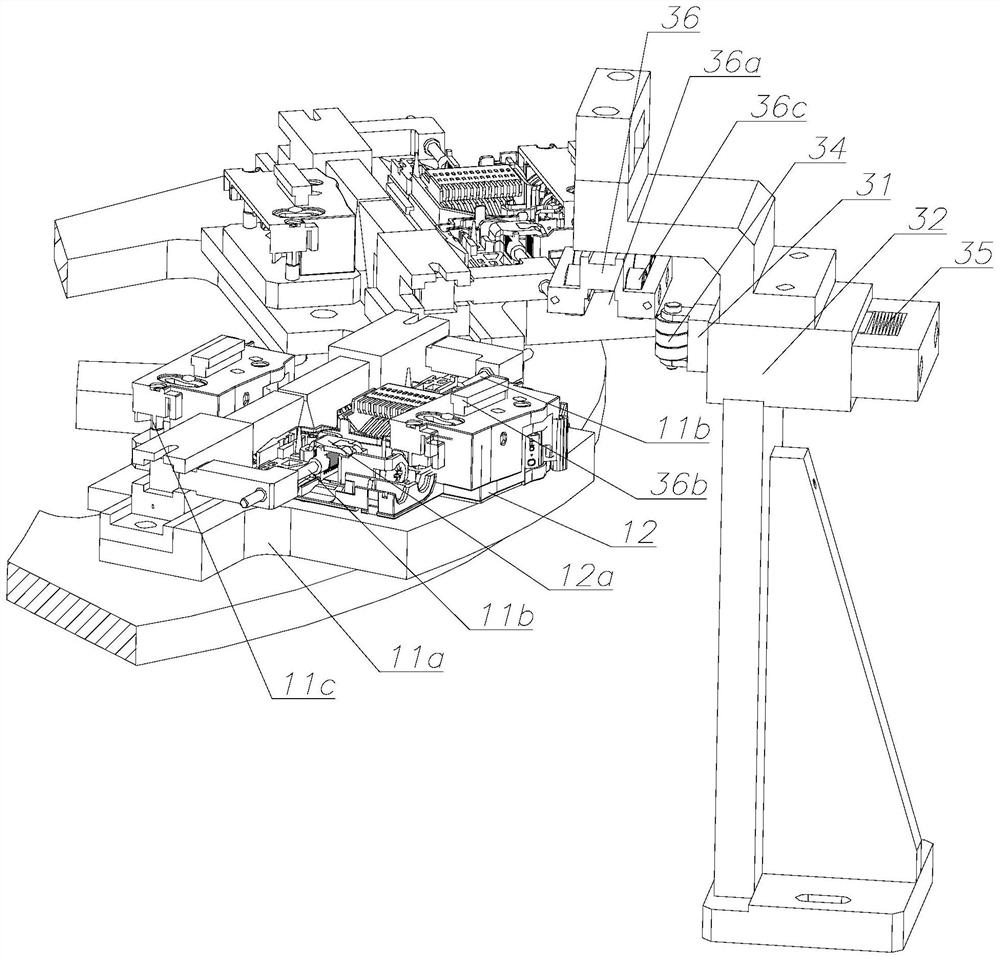

[0068] like Figure 10 An embodiment of the cap removal device 810 is shown, the cap removal device 810 includes a cap removal horizontal movement mechanism 812 supported by a cap removal base 811, and a cap removal vertical movement mechanism arranged on the cap removal horizontal movement mechanism 812 813, the cover removal vertical movement mechanism 813 is provided with a cover removal jaw cylinder 814 for grabbing the matching cover, the cover removal horizontal movement mechanism 812 can drive the cover removal vertical movement mechanism 813 to move in the horizontal direction, and the circuit breaker and the user Reciprocate between the fixed seats 11c that fix the matching cover, the vertical moving mechanism 813 for removing the cover can drive the cylinder 814 to reciprocate vertically, and the cylinder 814 for removing the cover clamps the matching cover from the circuit breaker. Driven by the cover removal horizontal movement mechanism 812 and the cover removal v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com