Electromagnetic operating mechanism and circuit breaker with same

A technology of electromagnetic operation and electromagnetic drive, which is applied in the direction of protection switch operation/release mechanism, circuit, contact drive mechanism, etc. It can solve the problems of inability to meet the test standards, slow operating mechanism, and large size of accessories, and achieve compact structure, Reduce the effect of zero mechanism and few components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

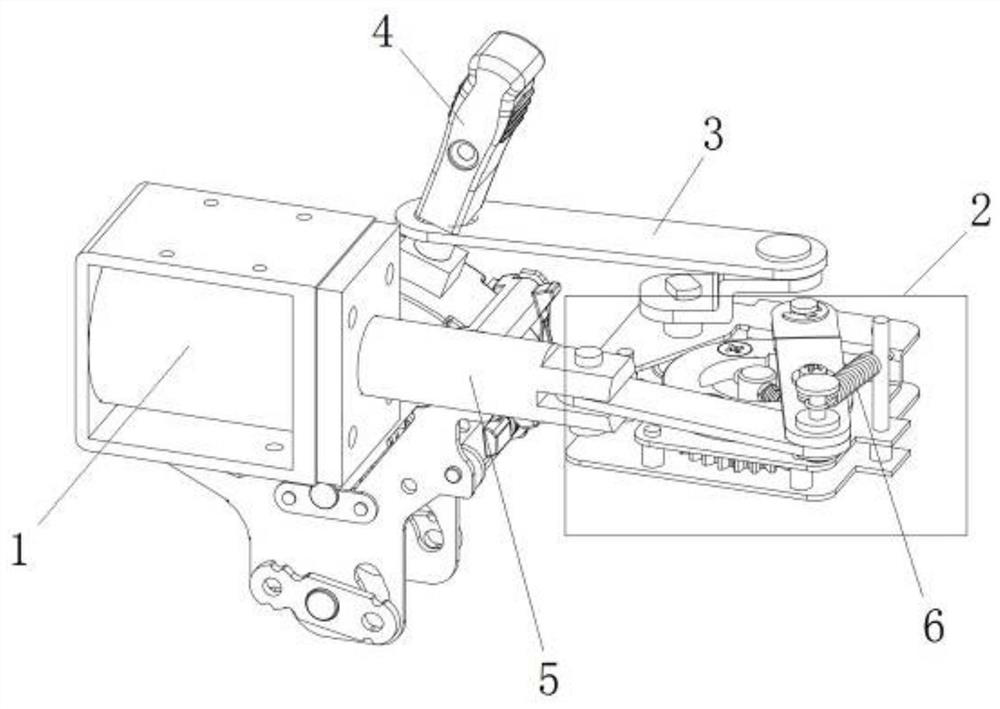

[0080] This embodiment provides a specific implementation of the electromagnetic operating mechanism, such as figure 1 As shown, it includes: an electromagnetic driver 1, a power conversion mechanism 2 and a pull rod 3. The power conversion mechanism 2 is used to convert the attraction force of the electromagnetic driver 1 into a reciprocating driving force for the closing handle 4 of the switch. Wherein, the moving iron core 5 of the electromagnetic driver 1 is also connected with a first elastic member 6, and the first elastic member 6 has a restoring force to drive the moving iron core 5 to move toward the release direction, that is: when the electromagnetic driver When 1 is released, the moving iron core 5 can be pulled out of the coil under the action of the first elastic member 6, which is a tension spring.

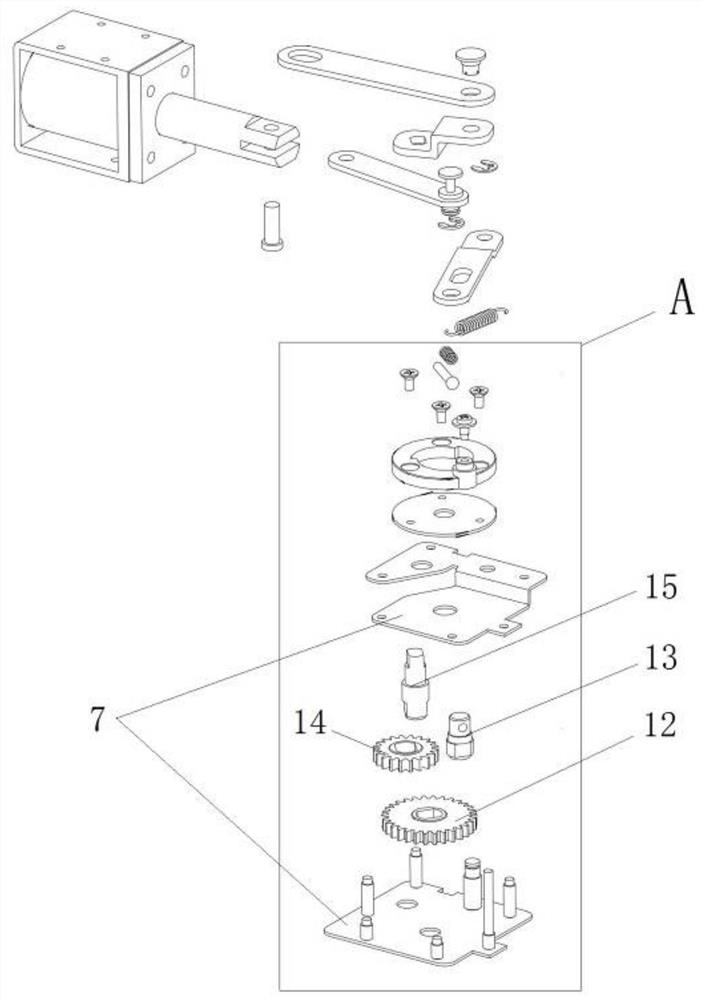

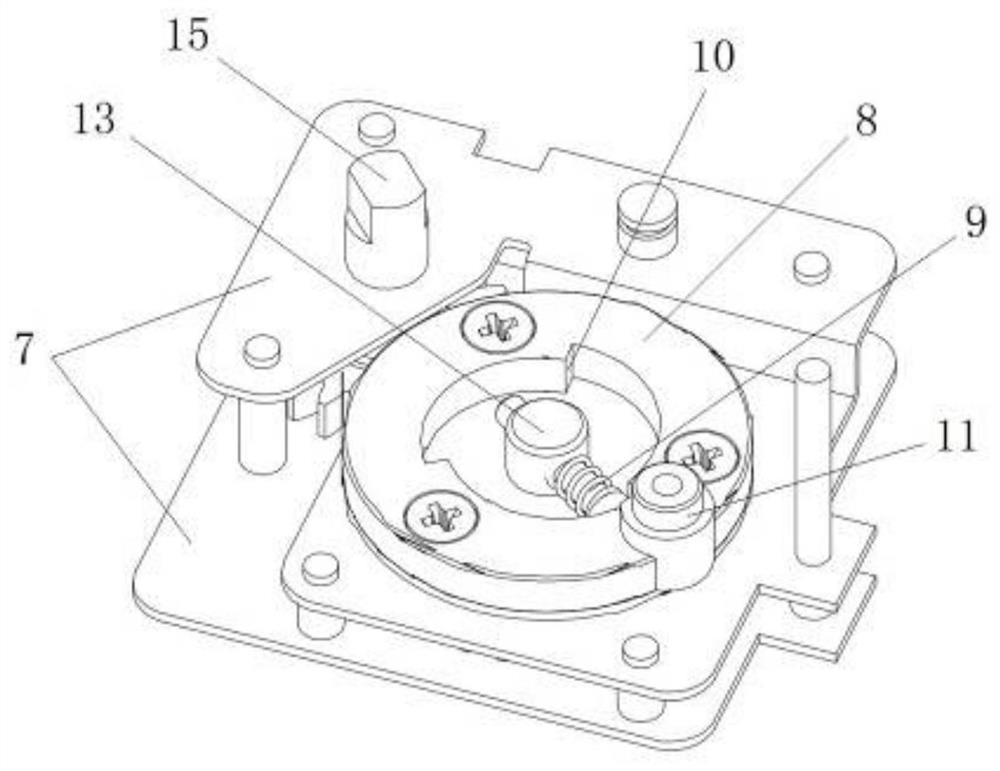

[0081] Such as figure 2 , image 3 As shown, the power conversion mechanism 2 includes: a ratchet mechanism and a gear mechanism, the gear mechanism is sandwich...

Embodiment 2

[0100] This embodiment provides a specific implementation of the electromagnetic operating mechanism, such as Figure 19 As shown, it includes: an electromagnetic driver 1, a power conversion mechanism 2 and a pull rod 3. The power conversion mechanism 2 is used to convert the attraction force of the electromagnetic driver 1 into a reciprocating driving force for the closing handle 4 of the switch. Wherein, the moving iron core 5 of the electromagnetic driver 1 is also connected with a first elastic member 6, and the first elastic member 6 has a restoring force to drive the moving iron core 5 to move toward the release direction, that is: when the electromagnetic driver When 1 is released, the moving iron core 5 can be pulled out of the coil under the action of the first elastic member 6, which is a torsion spring.

[0101] Such as Figure 19 , Figure 20 As shown, the power conversion mechanism 2 includes: a ratchet mechanism and a gear mechanism, the gear mechanism is dir...

Embodiment 3

[0115] This embodiment provides a specific implementation of a circuit breaker, including the electromagnetic operating mechanism described in Embodiment 1 or Embodiment 2, wherein the switch closing handle 4 of the circuit breaker is hingedly connected to the pull rod 3 of the electromagnetic operating mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com