Feeder for raising pigs

A feeder, No. 1 technology, applied in the field of livestock breeding, can solve the problems of waste of feed, blockage of the discharge port, blockage of the discharge port of the feed barrel, etc., and achieves the effect of reducing work intensity, avoiding blockage and preventing blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] All the features disclosed in this specification, except mutually exclusive features and / or steps, can be combined in any way.

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

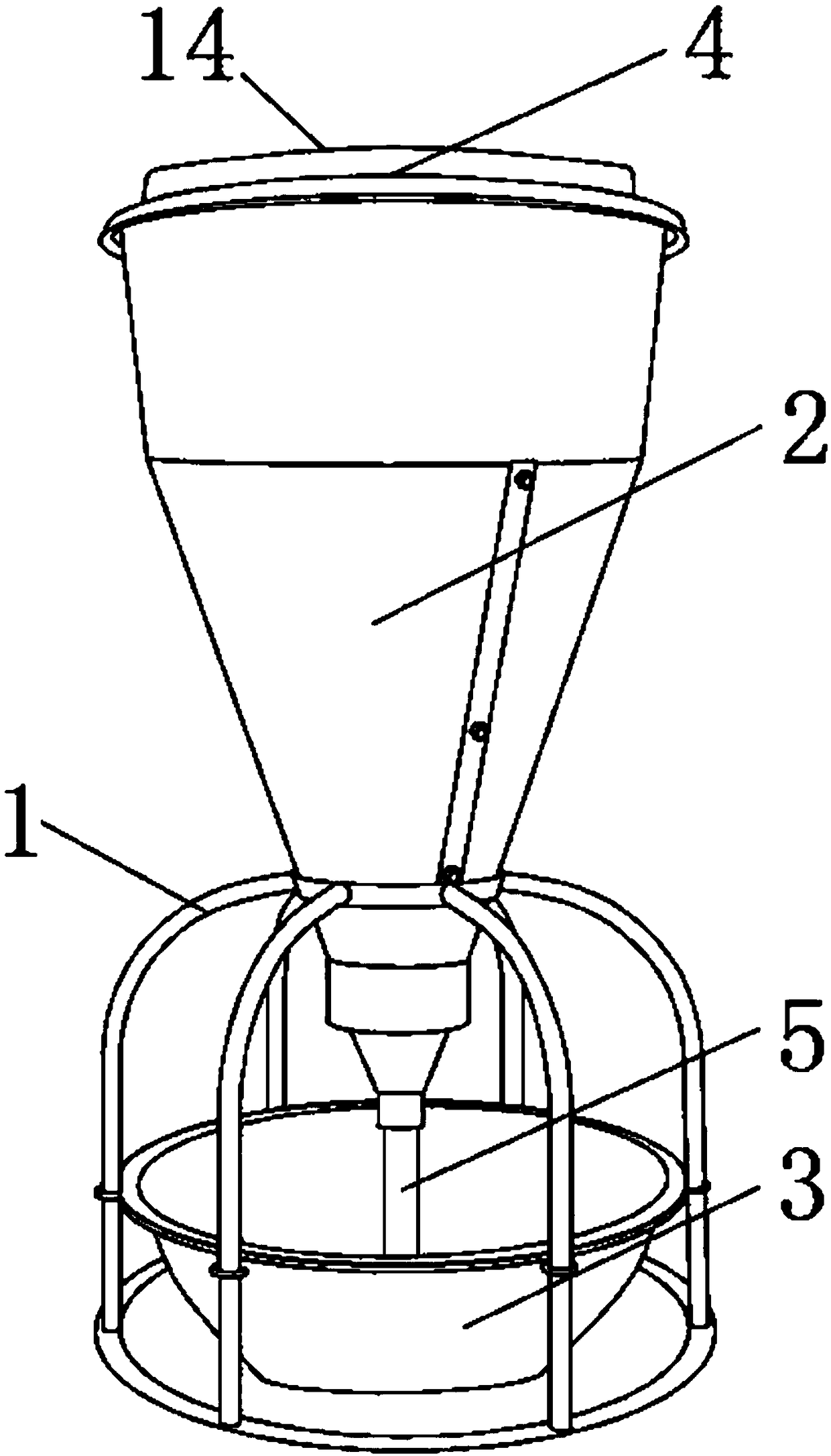

[0019] Such as figure 1 As shown, a pig feeder includes a bracket 1, a barrel body 2, and a trough 3. The barrel body 2 is vertically fixed on the bracket 1, and the top of the barrel body 2 is provided with a feeding port 4. The barrel body The bottom of 2 is provided with a discharge port 5, and the trough 3 is arranged at the bottom of the support 1, and the opening of the trough 3 is opposite to the opening of the discharge port 4.

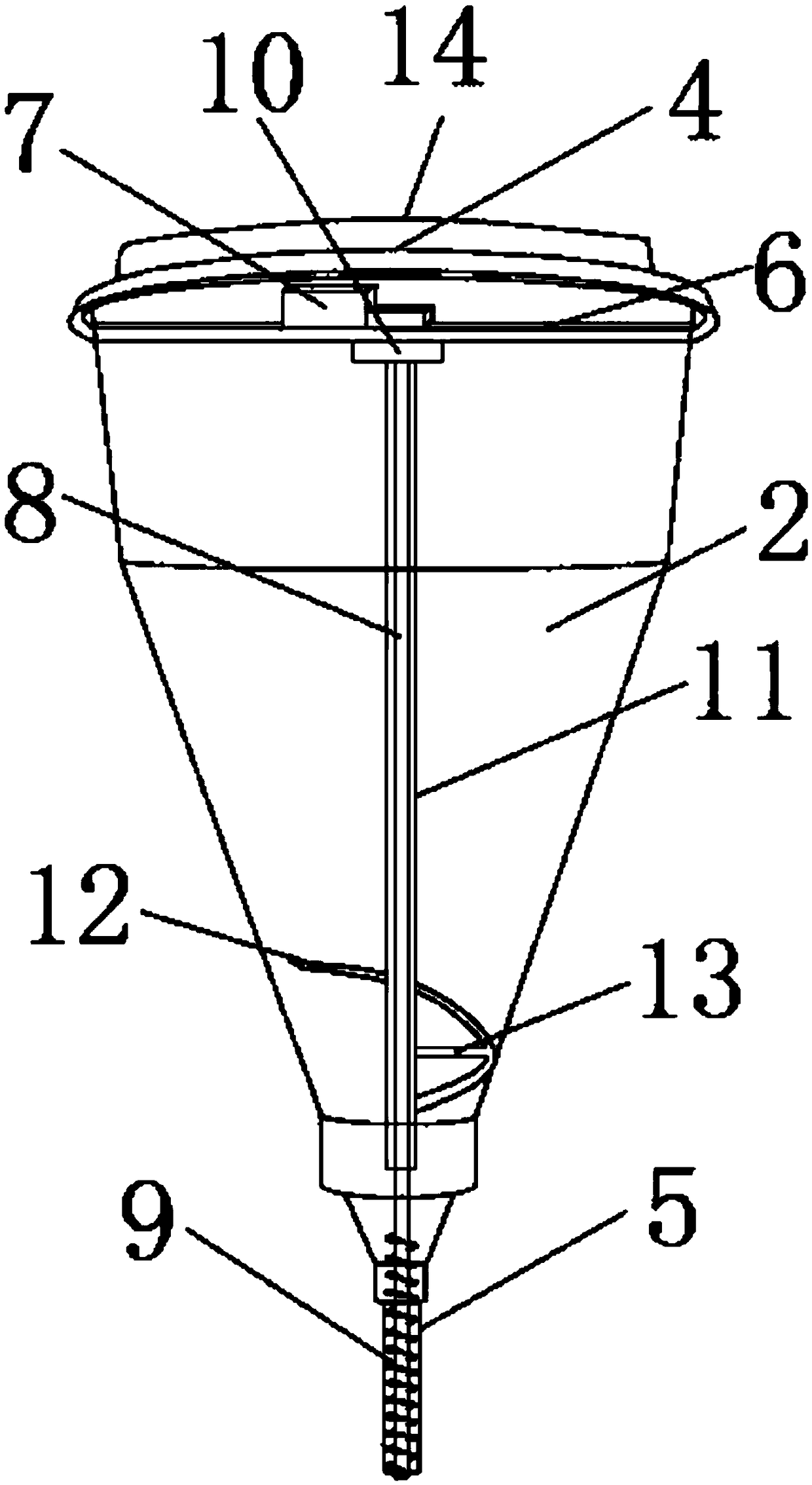

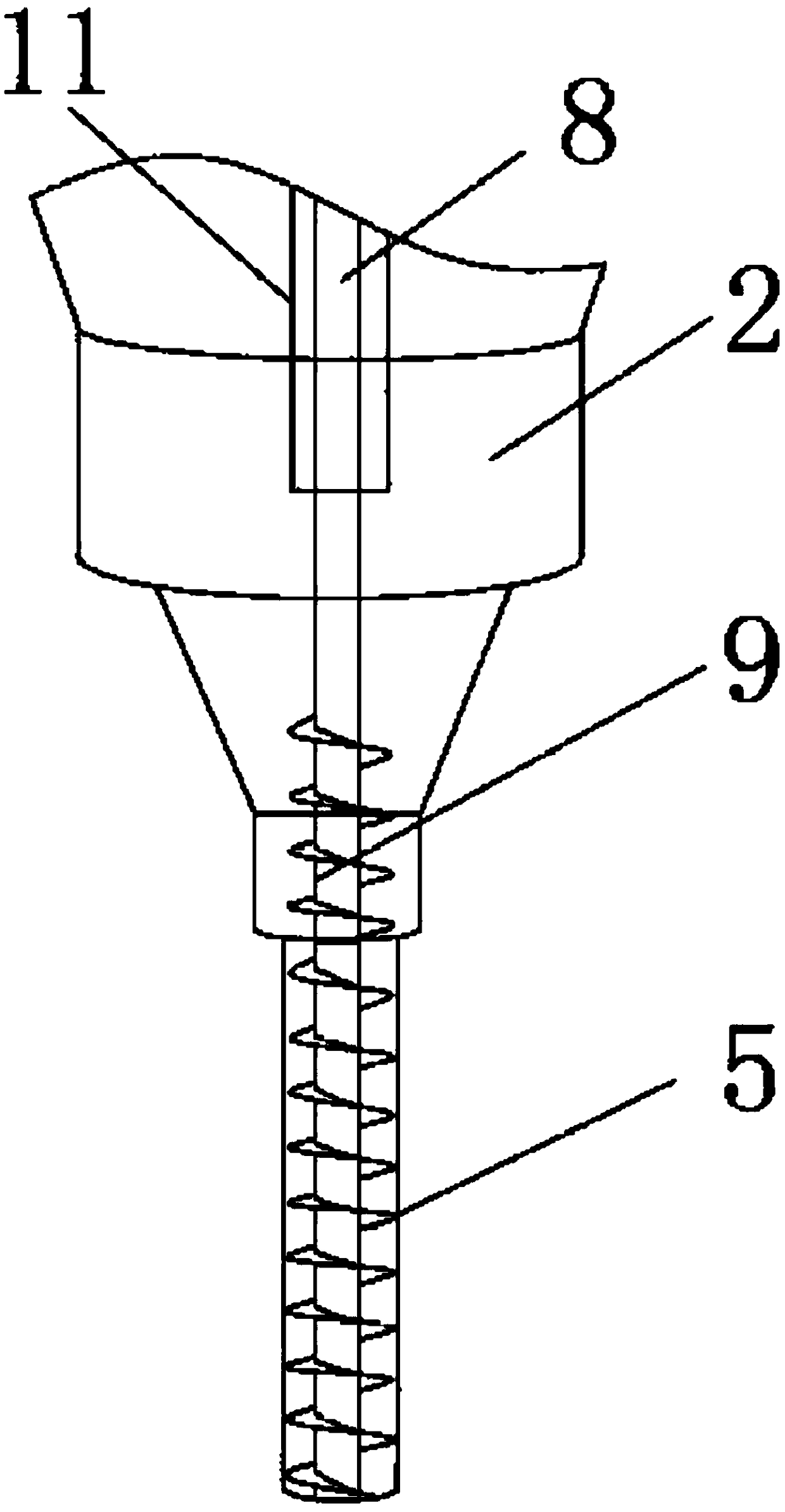

[0020] Such as figure 2 , image 3 As shown, the inner top surface of the barrel body 2 is provided with a crossbar 6, the crossbar 6 is provided with a motor 7, the output shaft of the motor 7 is provided with a No. 1 stirring rod 8, and the bottom of the No. 1 stirring rod 8 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com