Automatic lifting electric cook pot

A technology of automatic lifting and electric cooking pots, applied to the utensils with integral electric heating devices, the structure of cooking utensils, plug-ins, etc., can solve the problems of easy aging damage, dirt accumulation, leakage, etc., to avoid pollution of soup, Avoid damage, easy to clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

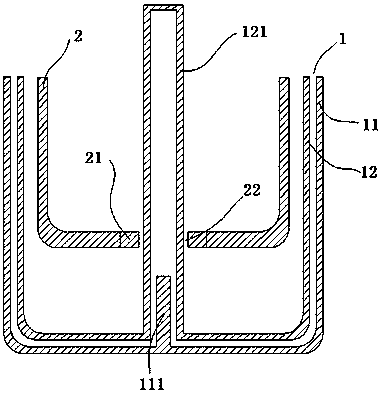

[0040] In one embodiment, the first magnetic device 111 is an electromagnet, and the second magnetic device 21 is a permanent magnet.

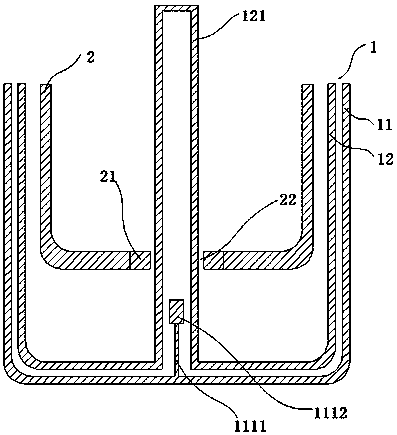

[0041] One of the implementations, such as figure 2 The first magnetic device 111 includes a magnetic component 1112 and a drive mechanism 1111 for driving the magnetic component 1112 to reciprocate up and down, and both the magnetic component 1112 and the second magnetic device 21 are permanent magnets.

[0042] In one embodiment, the inner pot 2 is an iron pot, and the second magnetic device 21 is the inner pot 2 itself, or the second magnetic device 21 is an iron block.

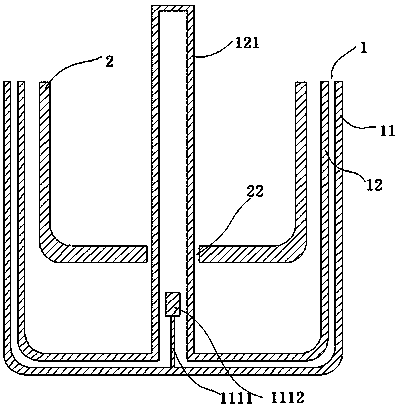

[0043] One of the implementations, such as Figure 4 , the sliding tube 121 is a hollow cylindrical tube with a closed upper end.

[0044] In one embodiment, the sliding tube 121 is a hollow square tube with a closed upper end.

[0045] In one of the implementation manners, the sliding pipe 121 and the outer pot 1 are integrally formed.

[0046] In one embodiment, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com