Efficient municipal sewage deep treatment system

A technology for urban sewage and advanced treatment, applied in chemical/physical processes, mixers with rotating containers, dissolution, etc., can solve the problems of low mixing efficiency, high labor intensity, poor mixing effect, etc., to improve mixing effect, automation High-level, fast stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

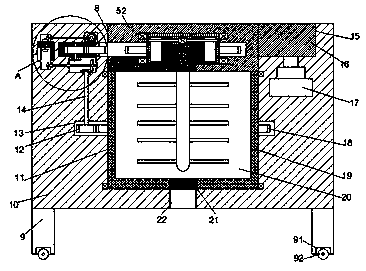

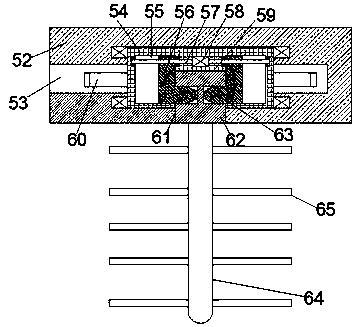

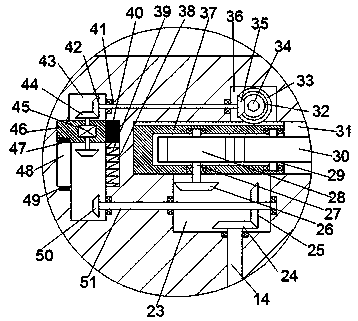

[0023] Such as Figure 1-3As shown, a high-efficiency urban sewage advanced treatment system of the present invention includes a body 10 fixedly arranged on the support frame 9 and a stirring structure arranged in the body 10, and the body 10 is provided with a first rotary cavity 11. The inner top wall of the first rotating chamber 11 is provided with a first connecting groove 8 connecting to the outside, and the left and right of the body 10 is extended with a second rotating chamber 13 penetrating through the first rotating chamber 11, so A stirring box 19 is rotatably installed in the first rotating cavity 11 through a bearing, and an outer ring gear 18 extending into the second rotating cavity 13 is fixedly arranged on the outer surface of the stirring box 19. A first sliding groove 31 is extended to the left in the left end wall of the communication groove 8, and a sliding block 37 is installed slidingly in the first sliding groove 31, and a third turning port facing rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com