Method of composite laser cleaning

A laser cleaning and laser technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low laser absorption rate, inability to clean, and low laser absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

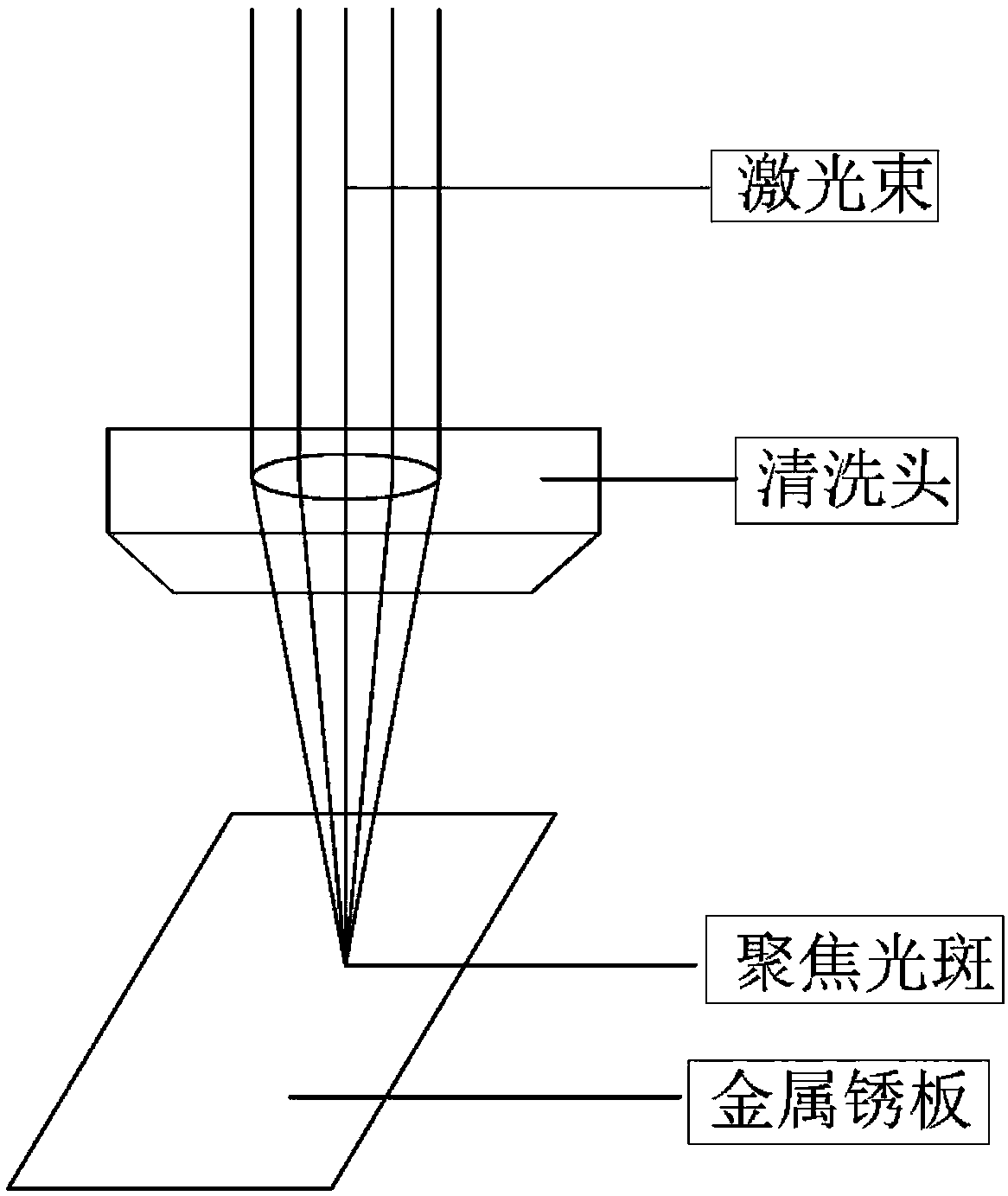

[0011] The present invention will be further described in conjunction with the accompanying drawings.

[0012] Such as figure 1 Shown, the present invention carries out by the following steps: (1), the laser beam that 915nm wavelength laser and 1080nm wavelength laser mix is converged to the metal rust plate surface through the optical system in the cleaning head, and the 915nm wavelength laser is carried out to the metal rust plate surface rust layer Preheat to increase the absorption efficiency of the rust layer to the laser. The 1080nm wavelength laser vaporizes the rust layer on the surface of the metal material, so that the rust layer on the surface of the metal rust plate absorbs the laser and vaporizes; (2), the cleaning head absorbs the gasified substance; (3), Move the cleaning head to make the focused light spot reciprocate linearly along the surface of the metal rust plate, and the cleaning head and the metal rust plate move relatively until the whole cleaning pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com