High-precision zirconium alloy plate rolling method

A zirconium alloy, high-precision technology, applied in the rolling field of high-precision zirconium alloy plates, can solve the problems of inability to meet the needs of the nuclear industry and limited precision control of plates, so as to avoid uneven rolling, reduce deformation resistance, and offset Effect of rolling unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] Step 1. Grinding the zirconium alloy slab until the same-slab difference is 0.15mm; the zirconium alloy slab is composed of the following components in mass percentage: Sn 1.15%, Nb 0.3%, Fe 0.4%, Cr 0.08%, O 0.1%, the balance is Zr and unavoidable impurities, the width of the zirconium alloy slab is 1000mm, the length is 2000mm, and the thickness is 12mm;

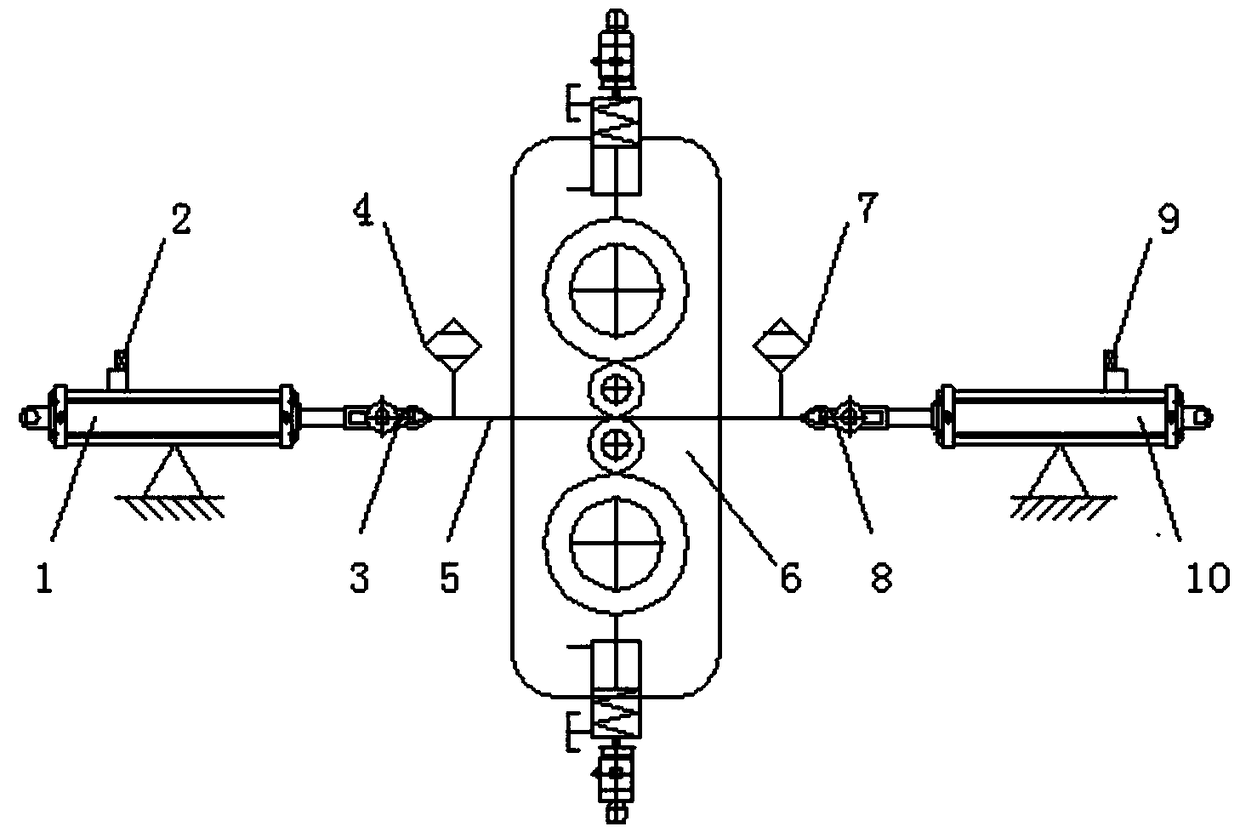

[0028] Step 2. Put the ground zirconium alloy slab in step 1 between the upper work roll 6-1 and the lower work roll 6-2 of the four-roll reversible plate mill 6, and then use the first hydraulic clamp 3 and the second hydraulic clamp 8 are respectively clamped on the two ends of the ground zirconium alloy slab 5, and then the first hydraulic cylinder 1 provided with the first tension sensor 2 and the first hydraulic cylinder 1 provided with the second tension sensor 9 are used Two hydraulic cylinders 10 make the ground zirconium alloy slab generate and maintai...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] Step 1. Grinding the zirconium alloy slab until the same-slab difference is 0.20mm; the zirconium alloy slab is composed of the following components by mass percentage: Sn 1.15%, Nb 0.3%, Fe 0.4%, Cr 0.08%, O 0.1%, the balance is Zr and unavoidable impurities, the width of the zirconium alloy slab is 800mm, the length is 1500mm, and the thickness is 8mm;

[0033] Step 2. Put the ground zirconium alloy slab in step 1 between the upper work roll 6-1 and the lower work roll 6-2 of the four-roll reversible plate mill 6, and then use the first hydraulic clamp 3 and the second hydraulic clamp 8 are respectively clamped on the two ends of the ground zirconium alloy slab 5, and then the first hydraulic cylinder 1 provided with the first tension sensor 2 and the first hydraulic cylinder 1 provided with the second tension sensor 9 are used Two hydraulic cylinders 10 make the ground zirconium alloy slab generate and maintain ...

Embodiment 3

[0036]Step 1. Grinding the zirconium alloy slab until the same-slab difference is 0.25mm; the zirconium alloy slab is composed of the following components in mass percentage: Sn 1.15%, Nb 0.3%, Fe 0.4%, Cr 0.08%, O 0.1%, the balance is Zr and unavoidable impurities, the width of the zirconium alloy slab is 300mm, the length is 1000mm, and the thickness is 5mm;

[0037] Step 2. Put the ground zirconium alloy slab in step 1 between the upper work roll 6-1 and the lower work roll 6-2 of the four-roll reversible plate mill 6, and then use the first hydraulic clamp 3 and the second hydraulic clamp 8 are respectively clamped on the two ends of the ground zirconium alloy slab 5, and then the first hydraulic cylinder 1 provided with the first tension sensor 2 and the first hydraulic cylinder 1 provided with the second tension sensor 9 are used Two hydraulic cylinders 10 make the ground zirconium alloy slab generate and maintain the front tension and the back tension respectively; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com