A metal workpiece clamping process

A metalworking and crafting technology, applied in metal processing equipment, storage devices, feeding devices, etc., can solve problems such as damage to hardware workpieces, incomplete fixing of hardware workpieces, etc., to improve quality, fix stability, and reduce stress and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

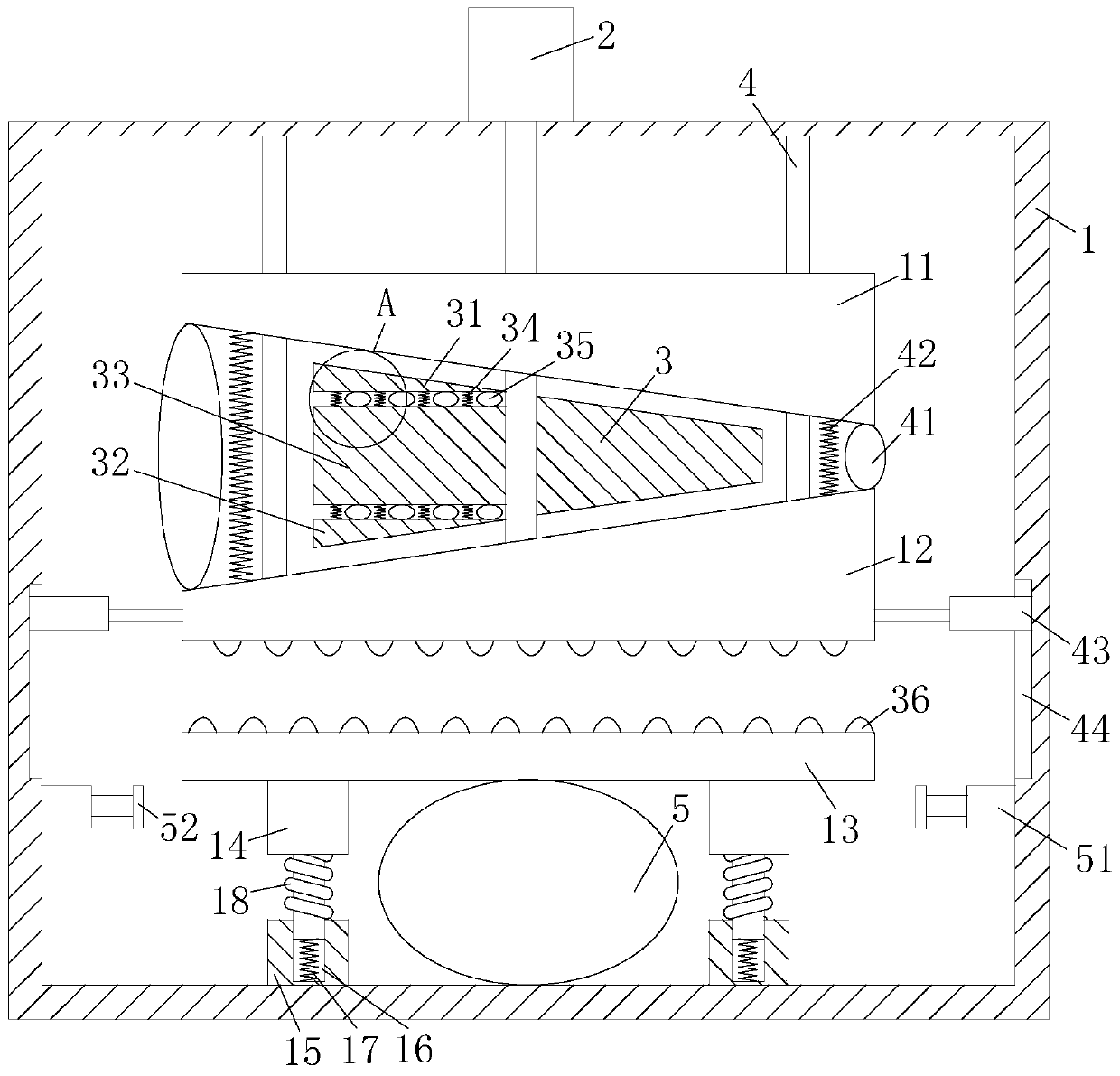

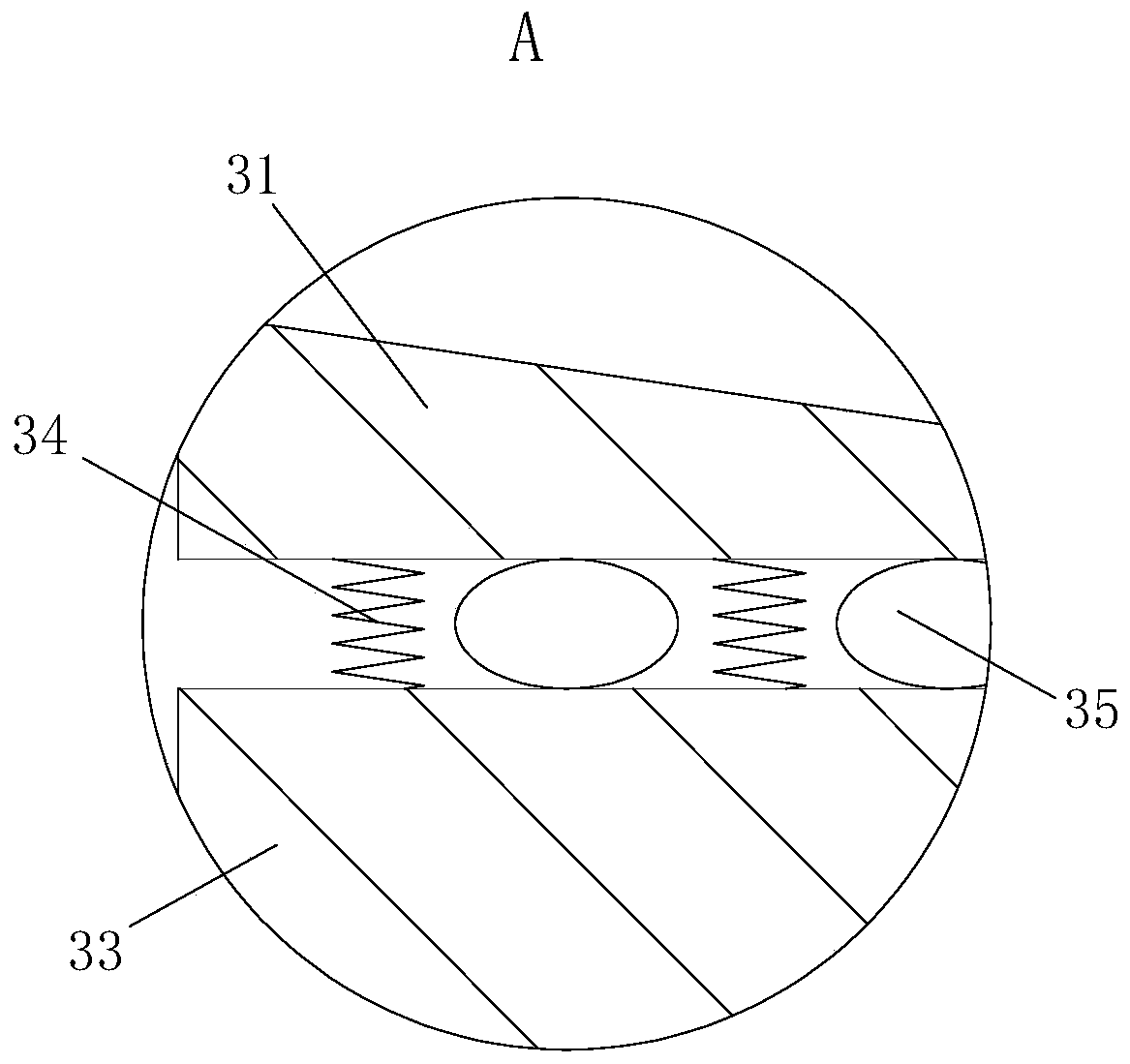

[0032] As an embodiment of the present invention, both sides of the rotating shaft of the motor 2 are provided with limit rods 4; the limit rods 4 are vertically arranged, and the upper ends of the limit rods 4 are fixedly connected to the top inner wall of the frame body 1, The lower end passes through the fixed block 11 and penetrates into the extruded block 12, and is respectively connected with the fixed block 11 and the extruded block 12 in rotation; when working, during the downward movement of the extruded block 12, due to the action of the limit rod 4, the extruded The briquetting block 12 can only move up and down vertically, which effectively prevents the briquetting block 12 from swinging, resulting in incomplete fixation of the hardware workpiece.

[0033] As an embodiment of the present invention, the side of the limit rod 4 away from the rotating block 3 is provided with a first air bag 41; the first air bag 41 is fixedly connected between the fixed block 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com