Friction welding equipment

A technology of friction welding and equipment, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems affecting processing efficiency and cumbersomeness, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

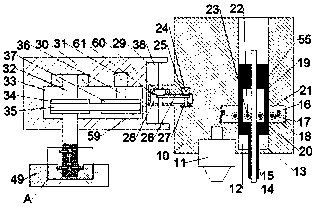

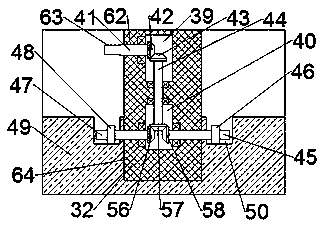

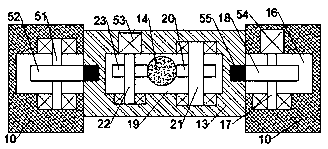

[0012] Combine below Figure 1-3 The present invention will be described in detail.

[0013] refer to Figure 1-3 , according to the friction welding equipment of the embodiment of the present invention, the friction welding main body support 10 is included, the stirring needle 11 is fixedly installed in the bottom end surface of the friction welding main body support 10, and the opening is provided in the friction welding main body support 10 Auxiliary device cavity 12, the auxiliary device cavity 12 is slidingly fitted with an auxiliary welding slide table 13 between the left and right walls, and the auxiliary welding slide table 13 extends downwards through the bottom end surface of the friction welding main body bracket 10. The auxiliary welding slide 13 is provided with a filling feeding chamber 19, the bottom wall of the filling feeding chamber 19 is provided with a feeding chamber 15 with an opening downward, and symmetrical installation teeth are fixed on the left and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap