Simple welding workbench capable of horizontally rotating

A workbench, horizontal technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems affecting the welding seam forming and quality, welding quality influence, poor arc stability, etc., to improve welding efficiency, Easy to operate and ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

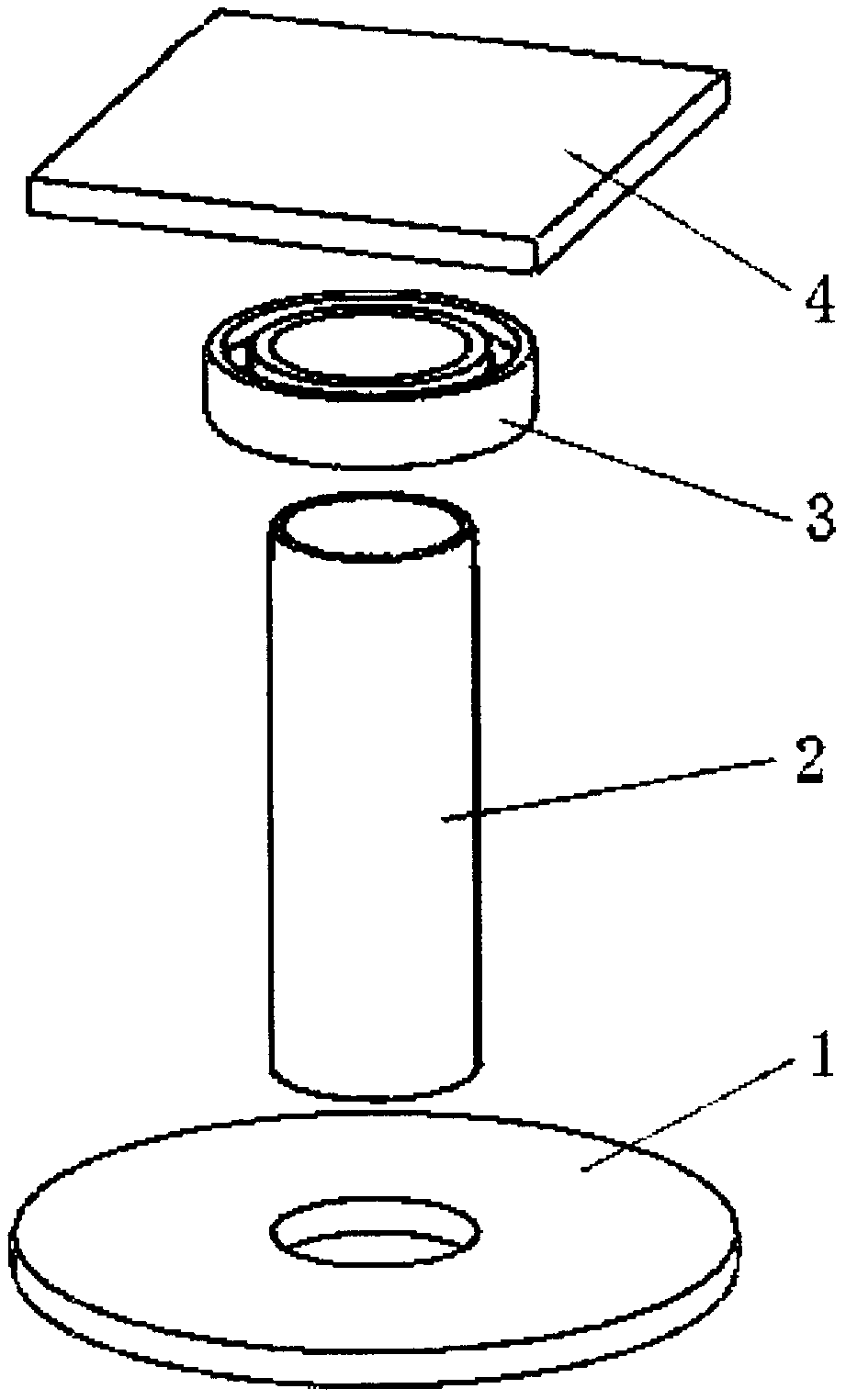

[0012] like figure 1 As shown, the present invention includes a base plate 1, a column 2, a rolling bearing 3 and a platform plate 4, the base plate 1 is circular, the column 2 is a steel pipe, the platform plate 4 is a rectangle, the lower end of the column 2 is vertically inserted into the center hole of the base plate 1, and the upper end is vertical Insert into the hole of the rolling bearing 3, fix the column 2, the base plate 1 and the inner ring of the rolling bearing 3 by spot welding; cover the platform plate 4 on the upper surface of the rolling bearing 3, and also use the spot welding method to connect the platform plate 4 and the outer ring of the rolling bearing 3 For fixing, in this way, using the principle that the outer ring of the rolling bearing 3 rotates around the inner ring, the platform plate 4 is horizontally rotated around the column 2, thereby realizing the change of the workpiece position on the platform plate 4.

[0013] The specific working process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com