Workpiece tightening all-purpose rotation stop mechanism and main reduction gear rotation stop and tightening mechanism

A main reduction gear and anti-rotation technology, applied in the field of automobile gearbox assembly, can solve problems such as easily damaged workpieces and poor anti-rotation effect, and achieve the effects of high integration, wide application range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

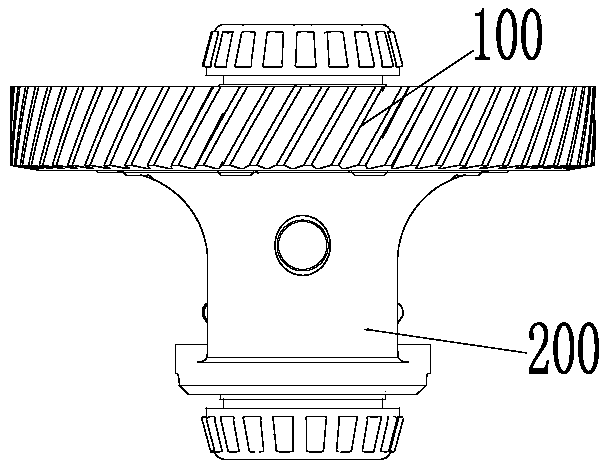

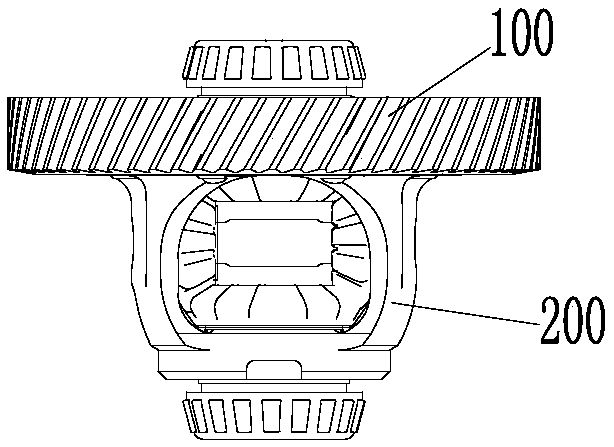

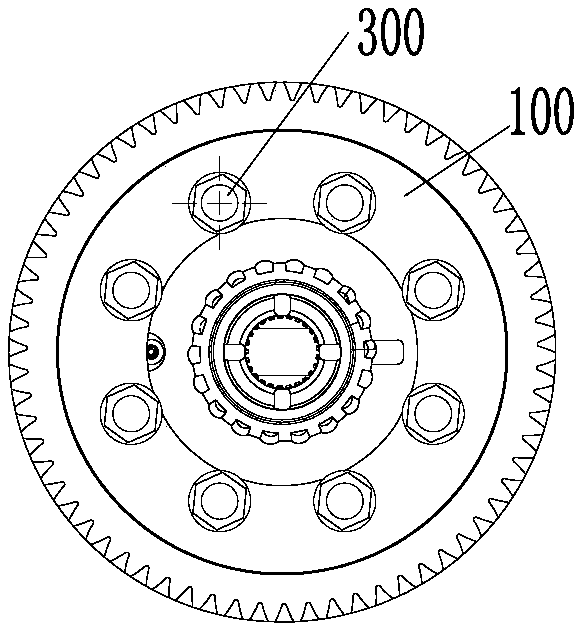

[0051] Figure 1 to Figure 9 Some embodiments according to the invention are shown.

[0052] The invention provides a main reduction gear anti-rotation tightening mechanism, which can realize the function of tightening and anti-rotation of main reduction gear bolts of various varieties and different sizes. As shown in Figure 2, the stop-rotation tightening mechanism for the main reduction gear includes: a workpiece tray 1, a guide head 3, a first spring 4, a linear bearing 6, a first sleeve pin 7, a conversion joint 8, a pad 9, a first Two sleeve bolts 10 , a tightening shaft mounting plate 11 , a tightening shaft 12 , a first sleeve O-ring 13 , a second sleeve O-ring 14 , and a pneumatic sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com