Drying device for producing rubber particles

A technology of rubber particles and drying device, applied in the drying field, can solve the problems of complex structure and poor drying device efficiency, and achieve the effects of improving drying quality, easy maintenance, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

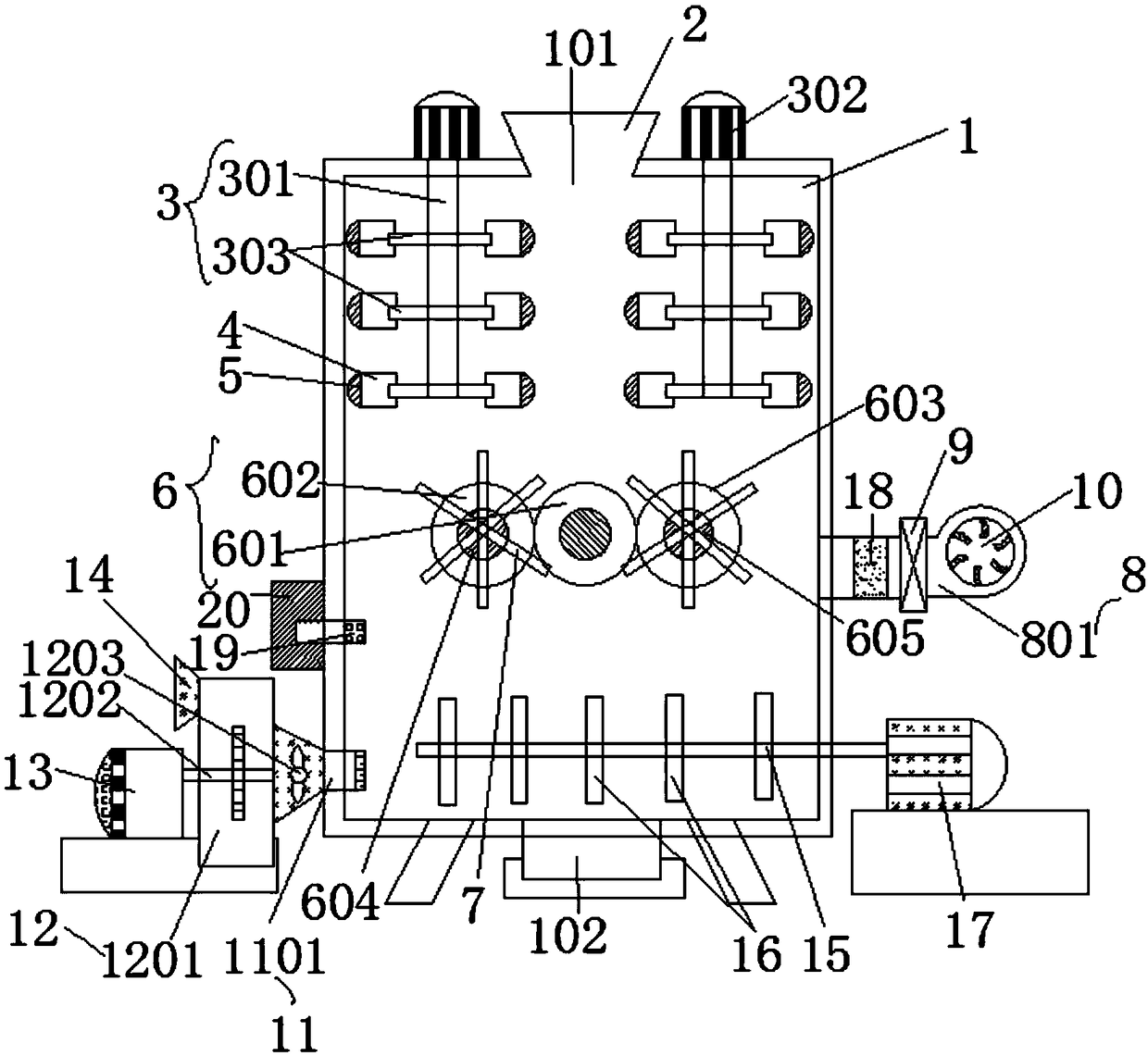

[0016] Embodiment 1: see figure 1 , a kind of drying device for the production of rubber granules provided by the present invention is now described, comprising a drying box 1, the upper end of the drying box 1 is provided with a feed inlet 101, and its lower end is provided with a discharge outlet 102, and the feed The mouth 101 is connected to the feeding hopper 2, and the two ends of the feeding hopper 2 are equipped with a feeding unit 3, and the feeding unit 3 includes a feeding shaft 301, and the upper end of the shaft body of the feeding shaft 301 is connected to a feeding motor 302, and the feeding unit 3 is connected to a feeding motor 302. Some feeding roller groups 303 are installed on the axle body of shaft 301, the two ends of described feeding roller group 303 are provided with disturbing material block 4, and curved surface material disturbing plate 5 is installed on the block body of described stirring block 4, described drying The height 1 / 2nd place of casing ...

Embodiment 2

[0017] Example 2: see figure 1 , as an improvement of the present invention, a filter layer 18 is also provided inside the pipe body of the ventilation pipe 1101, and the filter layer 18 adopts an activated carbon filter layer.

Embodiment 3

[0018] Embodiment 3: see figure 1 , as an improvement of the present invention, a humidity sensor 19 is provided inside the drying box 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com