Spliced door frame of fireproof door

A fire door, splicing technology, applied in fire doors, window/door frames, windows/doors, etc., can solve the problems of long time, affecting the overall assembly efficiency of fire door frames, and long splicing operation time of horizontal frames and mullion frames. , to achieve the effect of improving structural strength, shortening assembly time, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

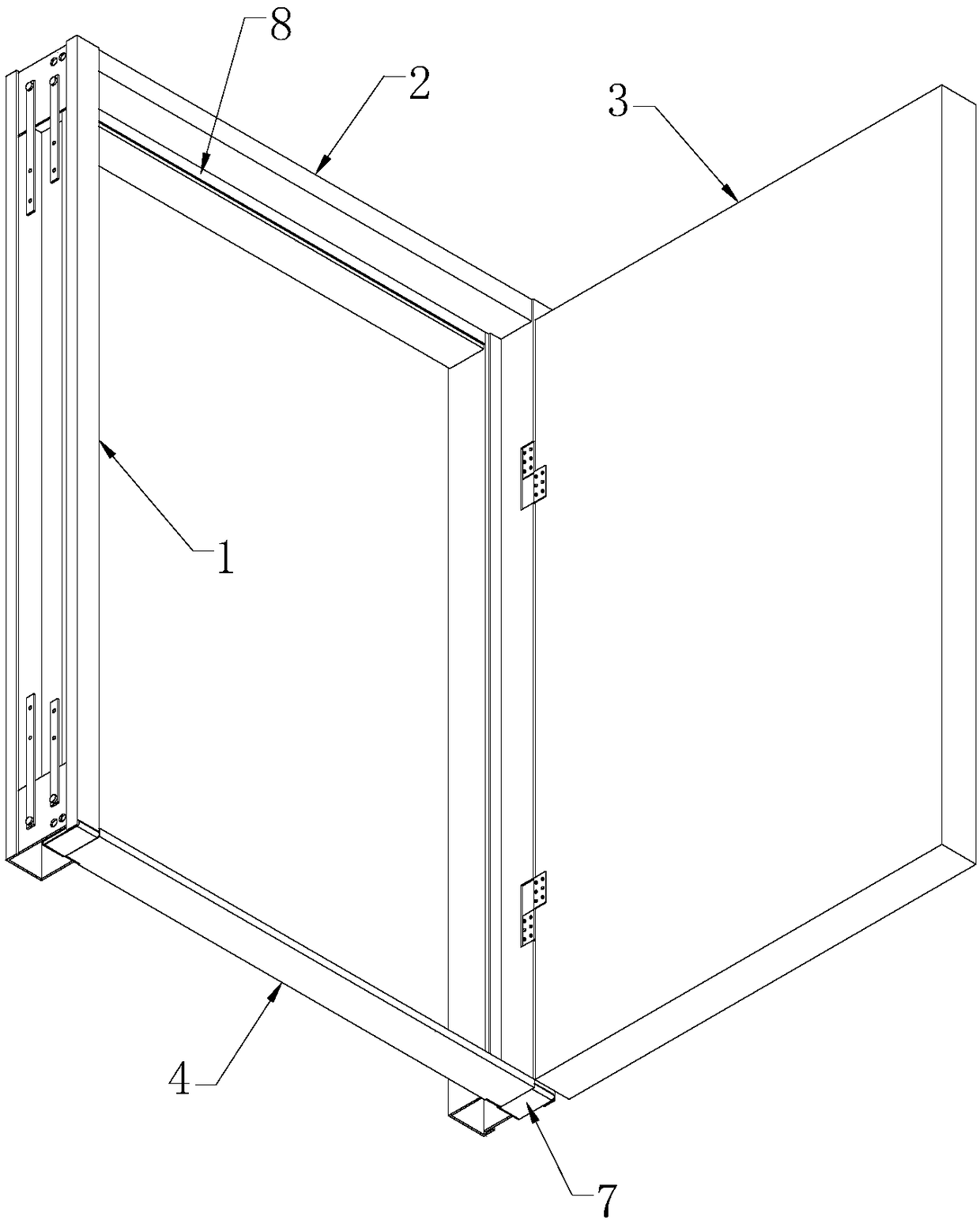

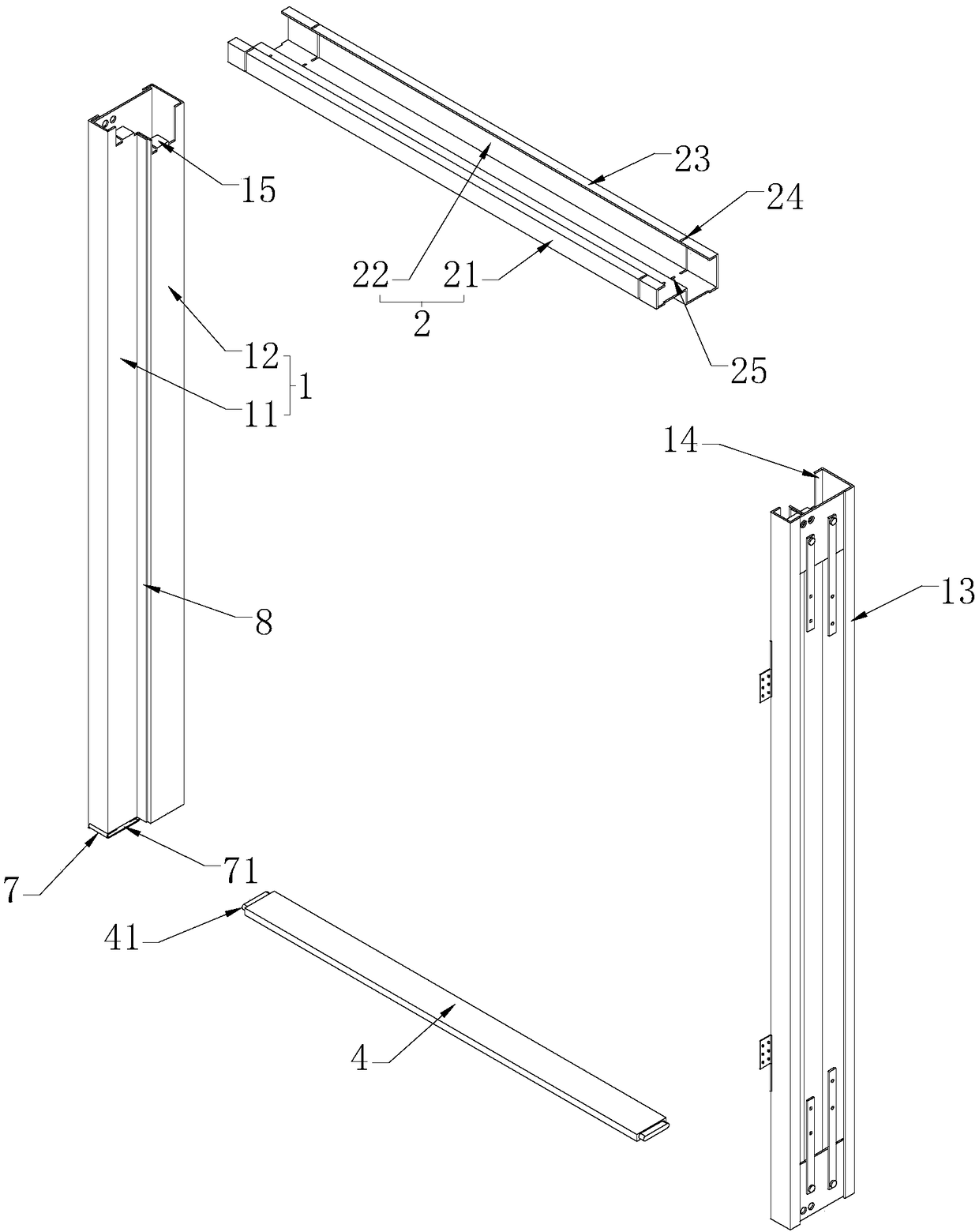

[0040] Such as figure 1 As shown, a spliced door frame for a fire door includes a square frame structure, the square frame structure includes two vertical frames 1 arranged in parallel at intervals, and the upper and lower ends of the two vertical frames 1 are respectively spliced with horizontal The frame 2 and the bottom plate 4, that is, the horizontal frame 2, the two vertical frames 1 and the bottom plate 4 are spliced to form a complete fire door frame structure. The spliced fire door frame structure does not require additional welding work and riveting fixing structure, which is convenient for assemblers to operate, and is conducive to shortening the time of fire door frame assembly work, thereby achieving the purpose of improving the overall efficiency of fire door frame assembly operations.

[0041] combine figure 1 and figure 2 As shown, the vertical frame 1 includes a vertical main frame 11 and a vertical frame 12 integrally formed into a stepped structur...

Embodiment 2

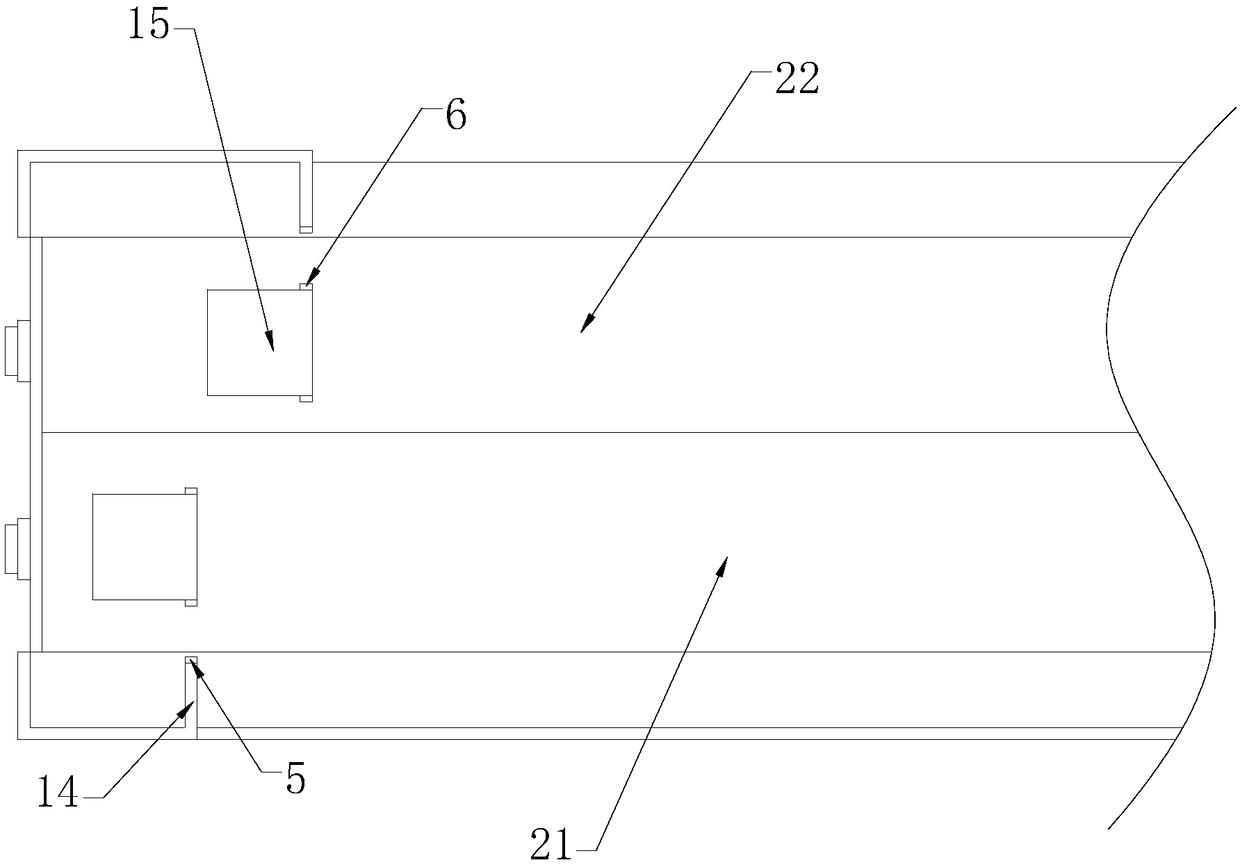

[0052] The difference between this embodiment and Embodiment 1 is that the plug-in fixing structures of the bottom plate 4 and the two vertical frames 1 are different, and the combination Figure 5 and Figure 6 As shown, the socket 71 on the vertical frame 1 is directly opened at the lower end of the side of the vertical frame 1, and the hole edge of the socket 71 extends toward the frame groove of the vertical frame 1 to form a ring-shaped fixing sleeve 711; When the base plate 4 is plugged and fixed with the two vertical frames 1 , the two ends of the base plate 4 are plugged into the two sockets 71 and extend along the fixing sleeve 711 to the inside of the frame groove of the vertical frame 1 .

[0053] combine Figure 5 and Figure 7 As shown, according to different types of fire doors and actual installation conditions, the bottom plate 4 also has different types, which mainly include two types of flat structure and stepped structure. When the bottom plate 4 is set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com