Disassembly tool for horizontal tails

A technology for dismantling tools and flat tails, which is applied in the direction of manufacturing tools, hand-held tools, aircraft parts, etc., can solve the problems of prolonging the production assembly cycle, increasing the assembly links of flat tails, small bearings and flat tail shafts that cannot be separated due to large clamping force, and achieving The effect of shortening the assembly work time, shortening the manufacturing cycle, and improving the efficiency of production work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further reflect the technical means, creative features, and realized functions of the present invention, the present invention will be described in detail below with reference to specific drawings and embodiments.

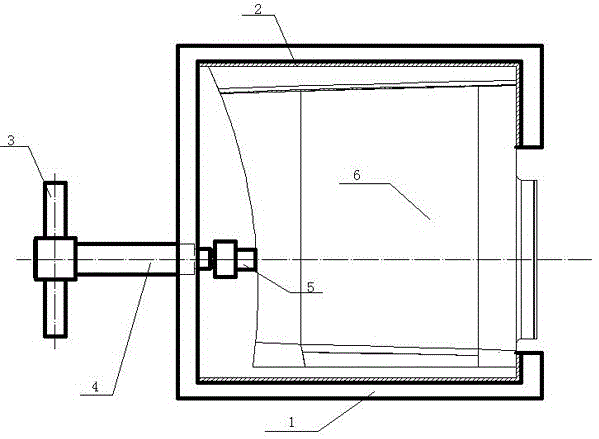

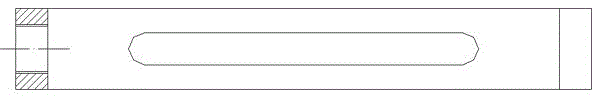

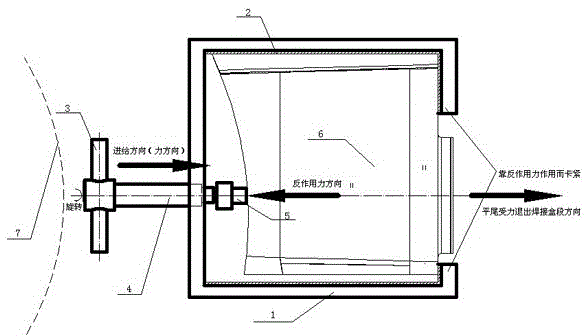

[0020] Such as figure 1 with figure 2 As shown, the flat-tail removal tool includes a positioner 1, rubber profile 2, handle 3, screw 4, pin 5. The rubber profile 2 is located at the contact surface of the positioner 1 and the rear bar section 6 of the product. The positioner 1 has bolt holes and The screw 4 is assembled, and the end surface of the screw 4 is matched with the end surface of the pin 5.

[0021] The positioner 1 is an unclosed structure with a steel groove, and its shape is based on the shape of the box section at the rear of the fuselage; and the upper and lower parts of the positioner are respectively provided with strip-shaped oval weight-reducing holes, and the left side of the positioner is provided The disassembly tool connects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com