Trimming machine of rotating circular disk starter propagation device

A koji-making device and a technology of rotating discs, which are applied in food preparation, application, food science, etc., can solve the problems of high cost, material cost, and prolonged frame assembly work time, achieving short assembly work time and cost reduction Effect

Active Publication Date: 2012-11-28

FUJIWARA TECHNO ART CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

That is, with the structure of the conventional frame 100 as described above, not only the time for assembling the frame is prolonged, but also the cost of materials is increased, and the cost becomes high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0049] Example: Deformation amount 2mm (maximum value) Cutting amount 3mm

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

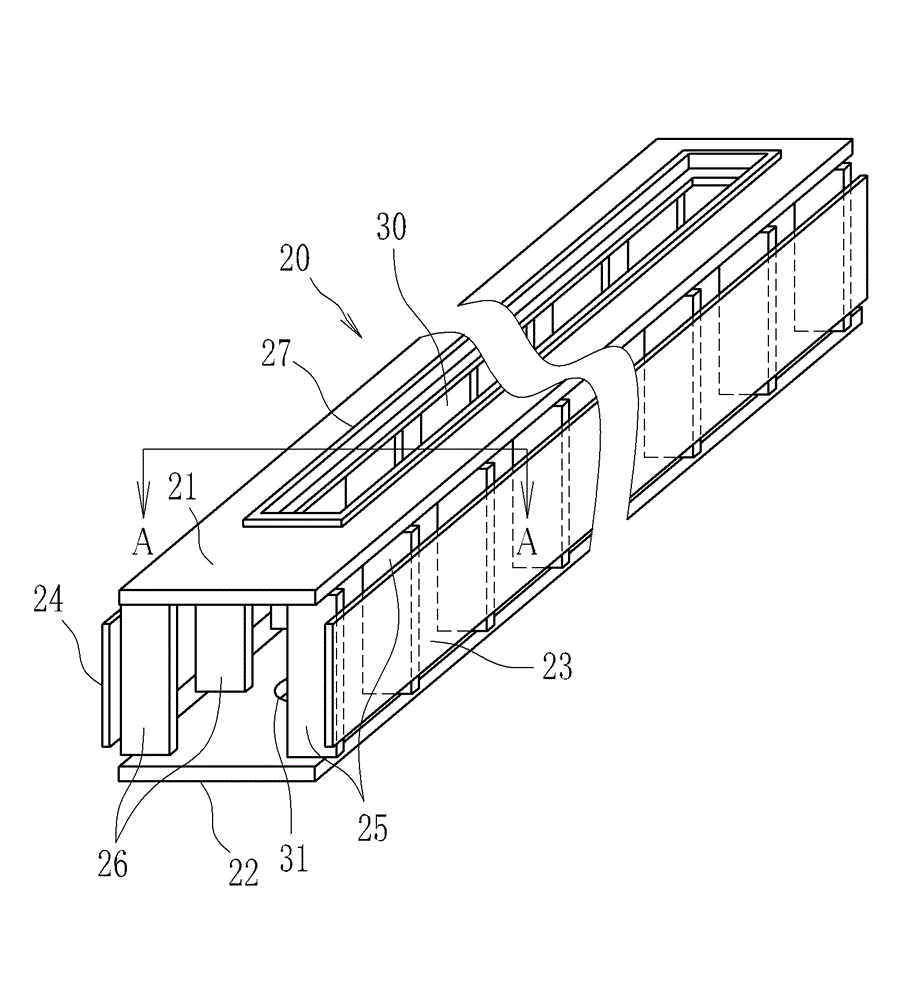

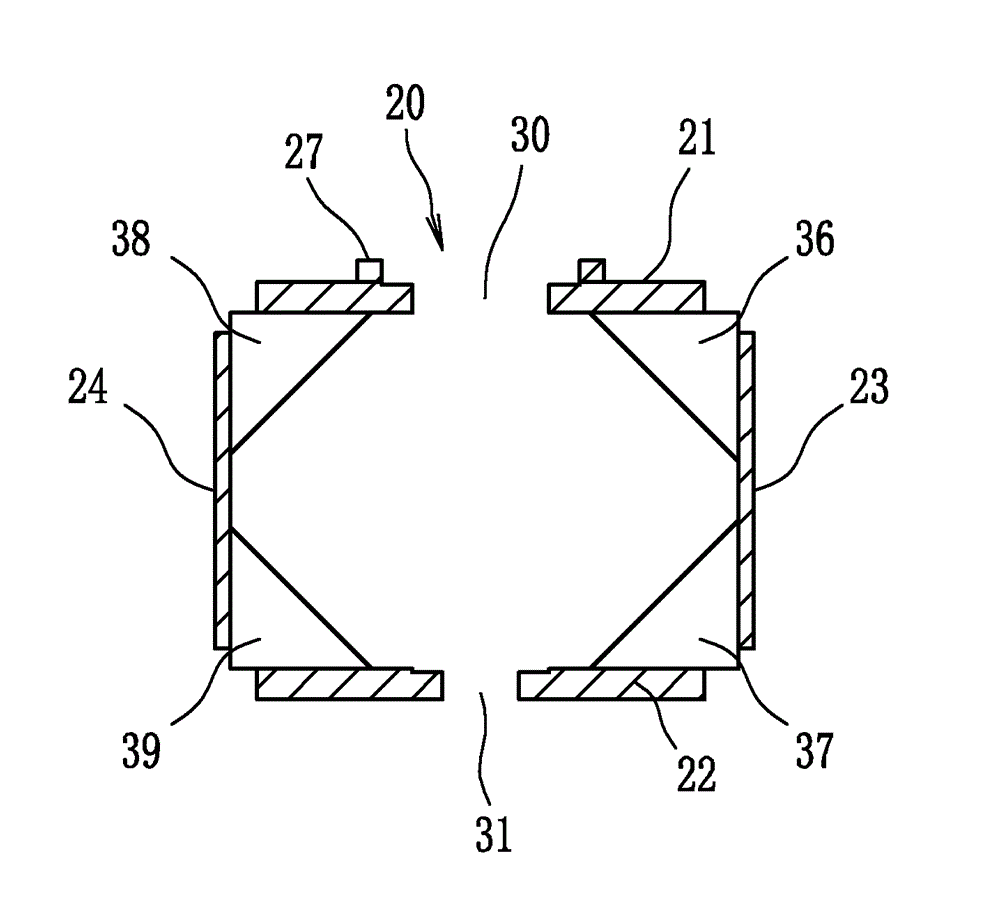

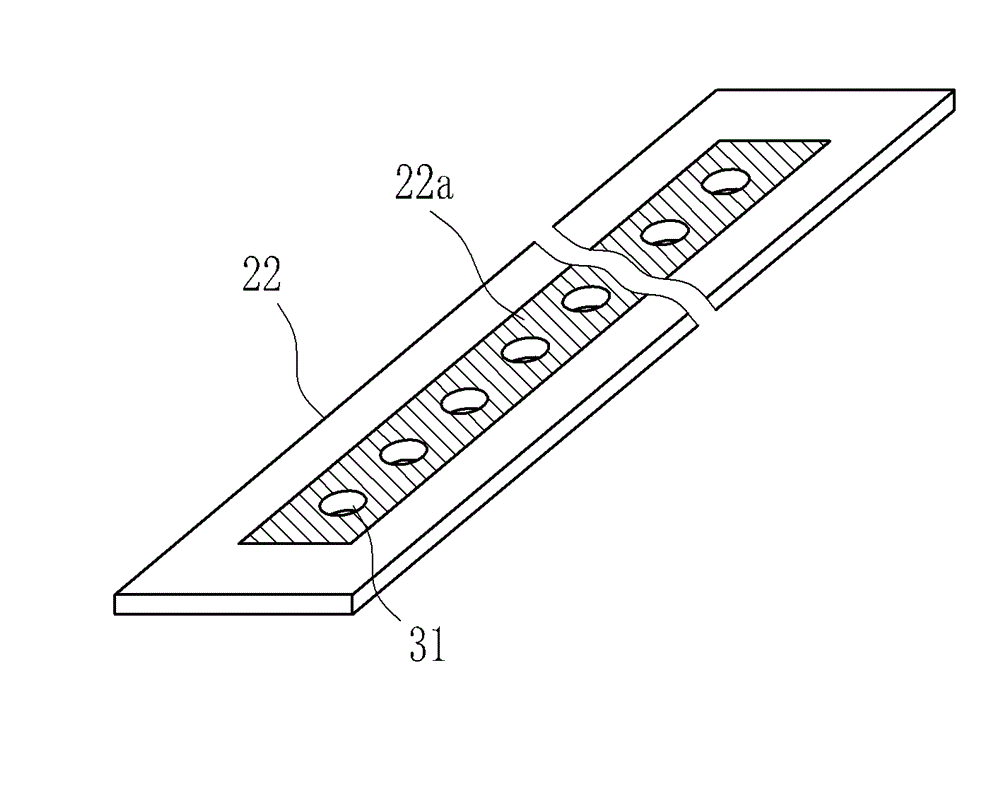

The invention provides a trimming machine of a rotating circular disk starter propagation device with a framework. By reducing deformation generated along with assembly, the assembly operation becomes easy, the material cost can be restrained, and the cost is reduced. According to the trimming machine (10) of the rotating circular disk starter propagation device (1), a screw rod (11) is arranged on the framework (20), wherein the framework (20) comprises a peripheral part formed by a plurality of separated strip components (21 to 24), and the separated strip components are fastened with one another through a fastening component (25) and a fastening component (26). In the structure, the strip components can be assembled with one another to form the framework (20) without heat sealing, and the deformation generated along with the assembly of the framework (20) is reduced. Therefore, the cutting processing amount of the framework (20) for realizing the mounting accuracy of the screw rod (11) is reduced. Thus, the time of the assembly operation can be shortened, and the plate thickness of the framework (20) is not required to be particularly thick to ensure the cutting processing amount.

Description

technical field [0001] The invention relates to a frame structure of a finishing machine of a rotating disc koji making device. Background technique [0002] In the rotating disc koji making device, filamentous fungi are cultivated while aerating the solid culture material. During cultivation, it is necessary to periodically stir the solid culture material to make it uniform. This stirring is called dressing (手入れ). In general, in a large-scale rotating disc koji making apparatus that accumulates solid culture raw materials such as soy sauce koji by 45 to 70 cm, a trimmer with a screw attached to the frame is used for trimming (for example, Patent Document 1). [0003] Figure 7 A perspective view showing an example of a frame of a conventional finisher. also, Figure 8 express Figure 7 Sectional view of the B-B line. The outer peripheral portion of the frame 100 is formed by joining end faces of a pair of elongated members 101 and 102 to each other. The mating portion...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L1/238A23L1/24A23L27/50A23L27/60

Inventor 狩山昌弘藤原惠子矢泽真裕

Owner FUJIWARA TECHNO ART CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com