Blade device for flow power generation

A blade and fluid technology, which is applied in the field of blade devices for hydropower generation, can solve the problems of not being able to fully function the blades 122 and reducing the power generation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following description, similar or identical elements will be denoted by the same reference numerals.

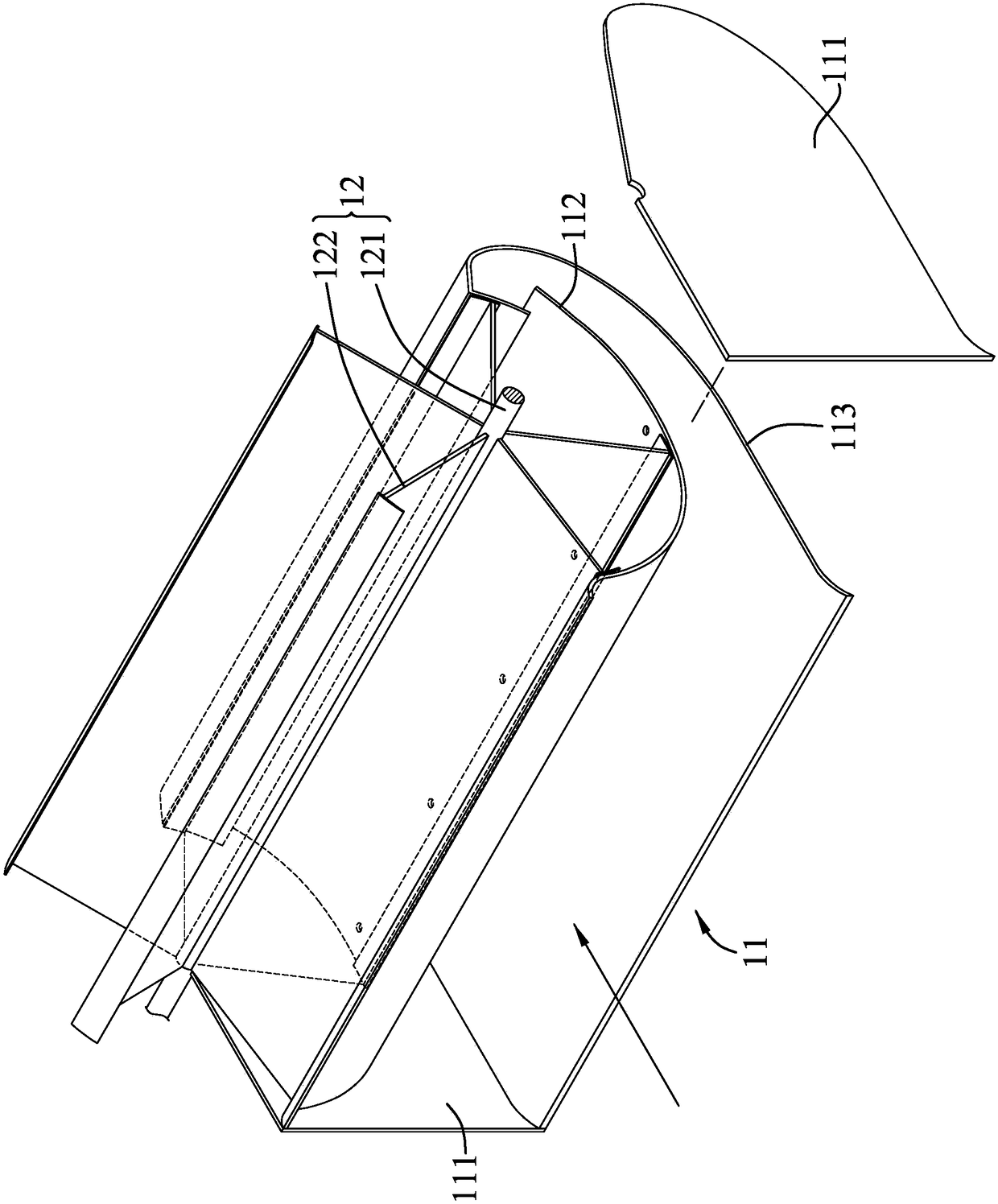

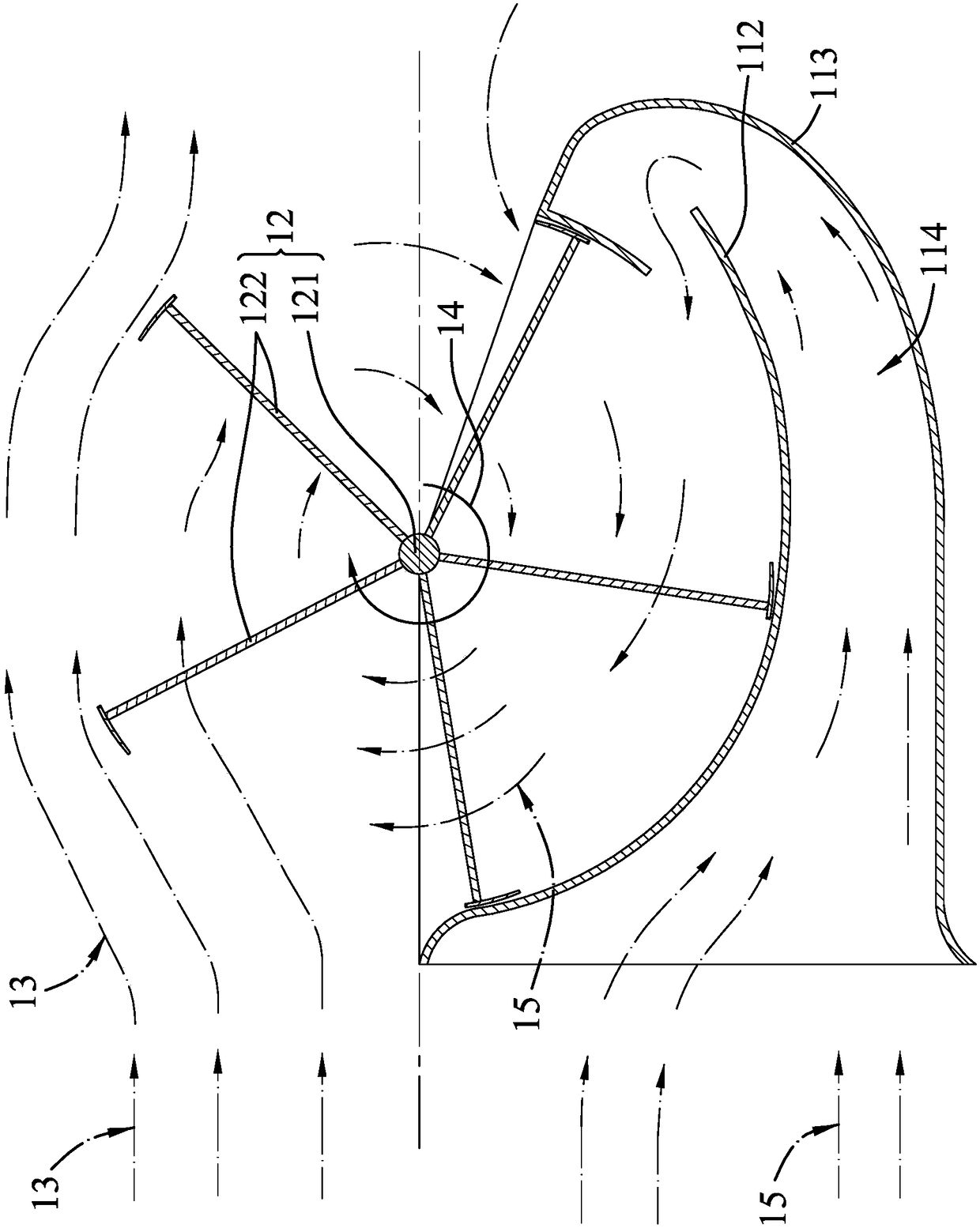

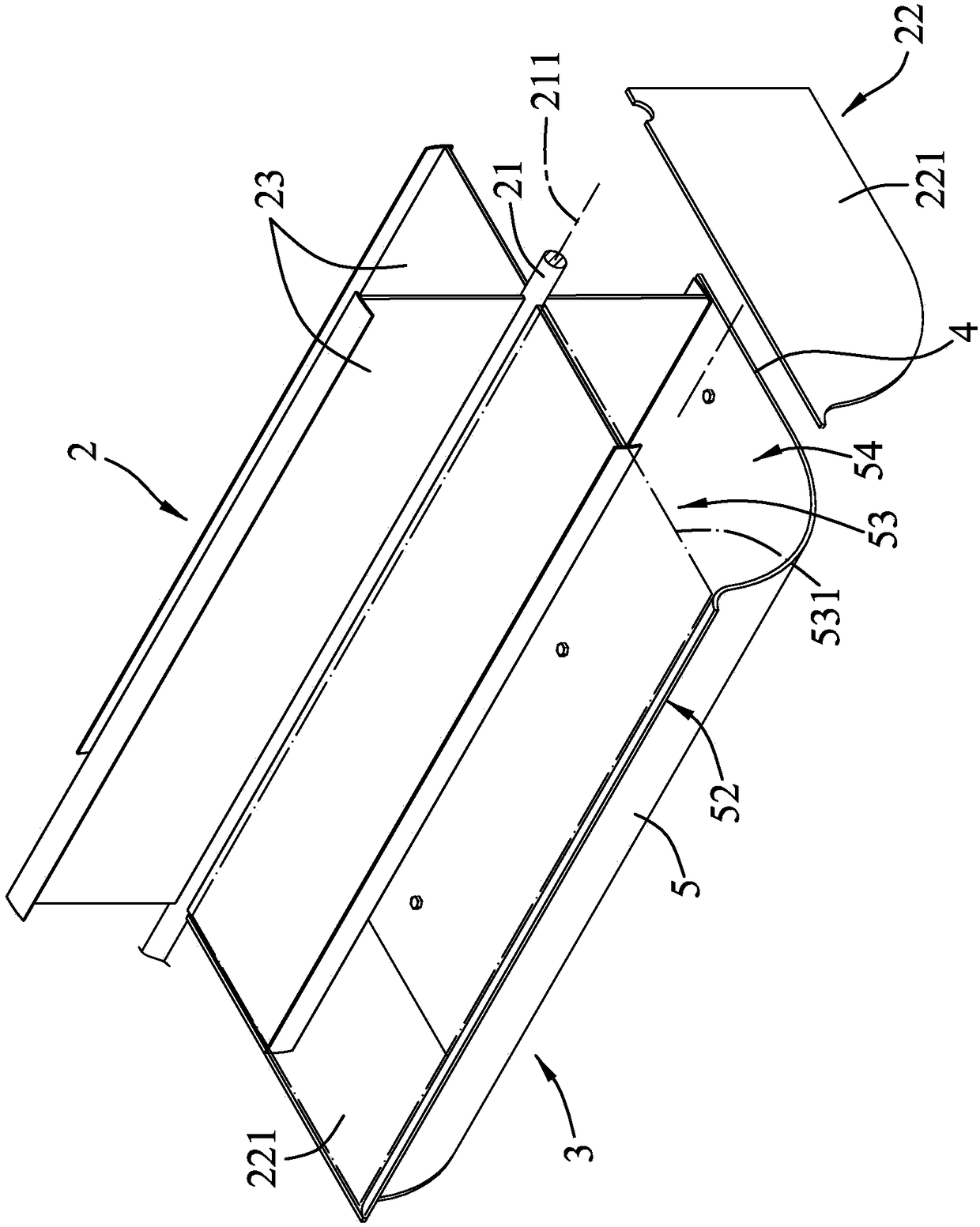

[0025] refer to image 3 and Figure 4 , a first embodiment of the blade device for flow power generation of the present invention is suitable for use with a fluid flowing forward and a generator (not shown). The fluid can be wind or water for wind or hydroelectric power generation. The first embodiment includes a rotating unit 2 and a base unit 3 assembled with the rotating unit 2 .

[0026] The rotating unit 2 includes a rotating shaft 21 extending left and right and connected to the generator set, a first supporting group 22 for pivoting the rotating shaft 21 , and four blades 23 extending radially outward from the rotating shaft 21 . The first supporting group 22 includes two side panels 221 spaced apart from each other and connected to the left and right sides of the base unit 3 respectively. One end of the rotating shaft 21 is rotatably pivoted on a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com