Gear transmission case capable of enabling tricycle to turn round in situ

A technology of gear transmission box and in-situ U-turn, applied in the direction of gear transmission, transmission, differential transmission, etc., can solve the problems of difficult to widen the plowing road, less transportation, and slow transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

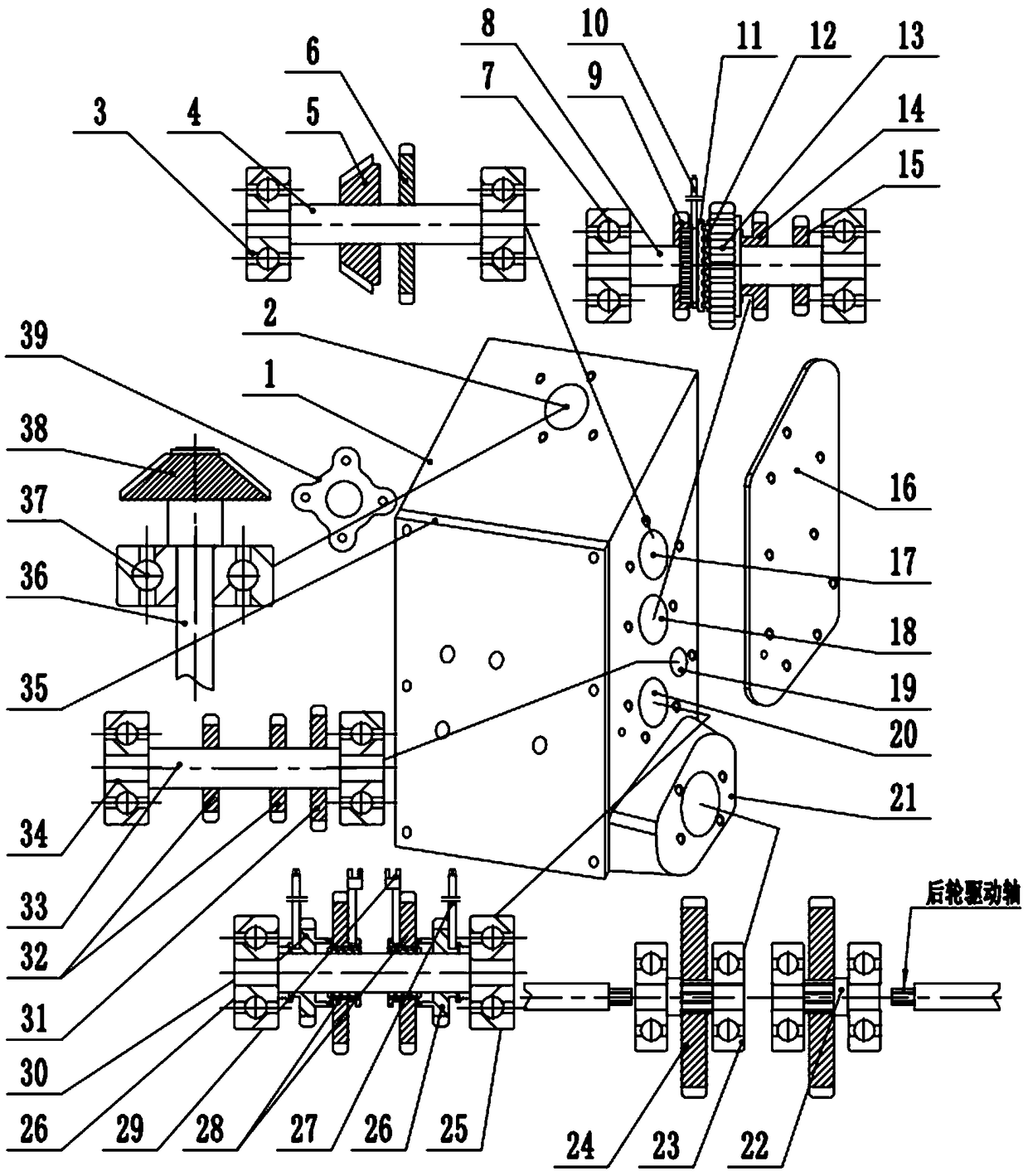

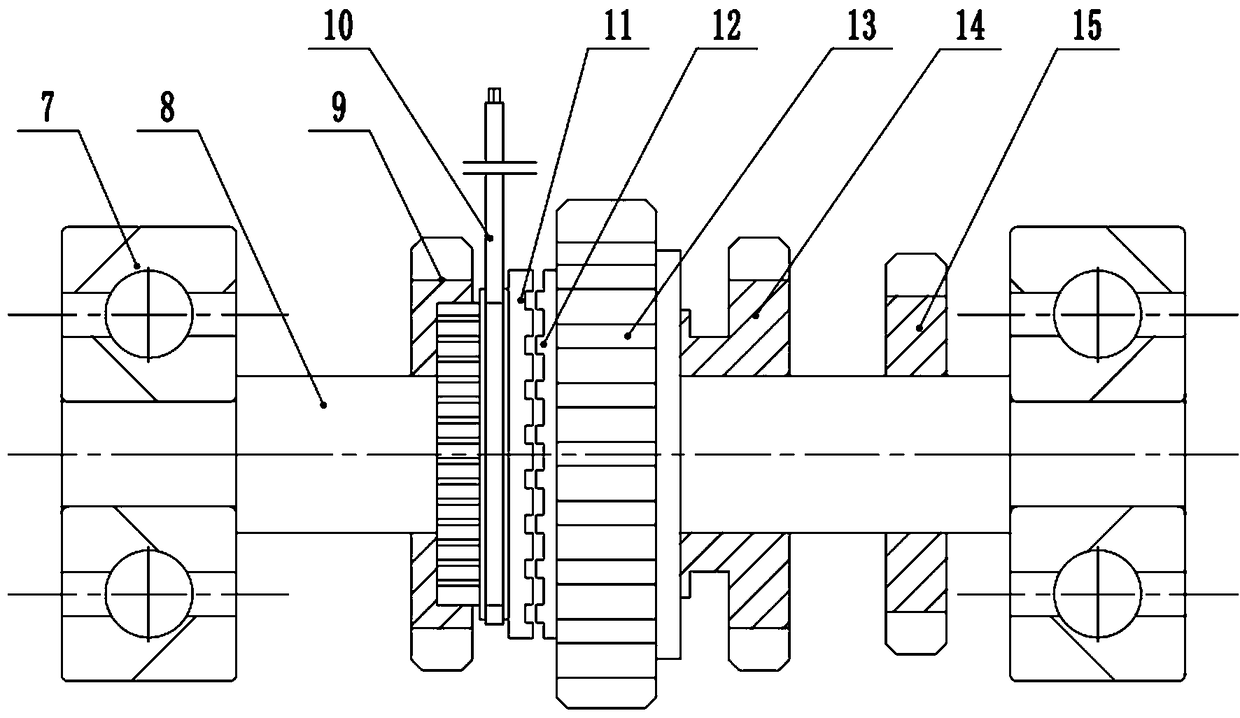

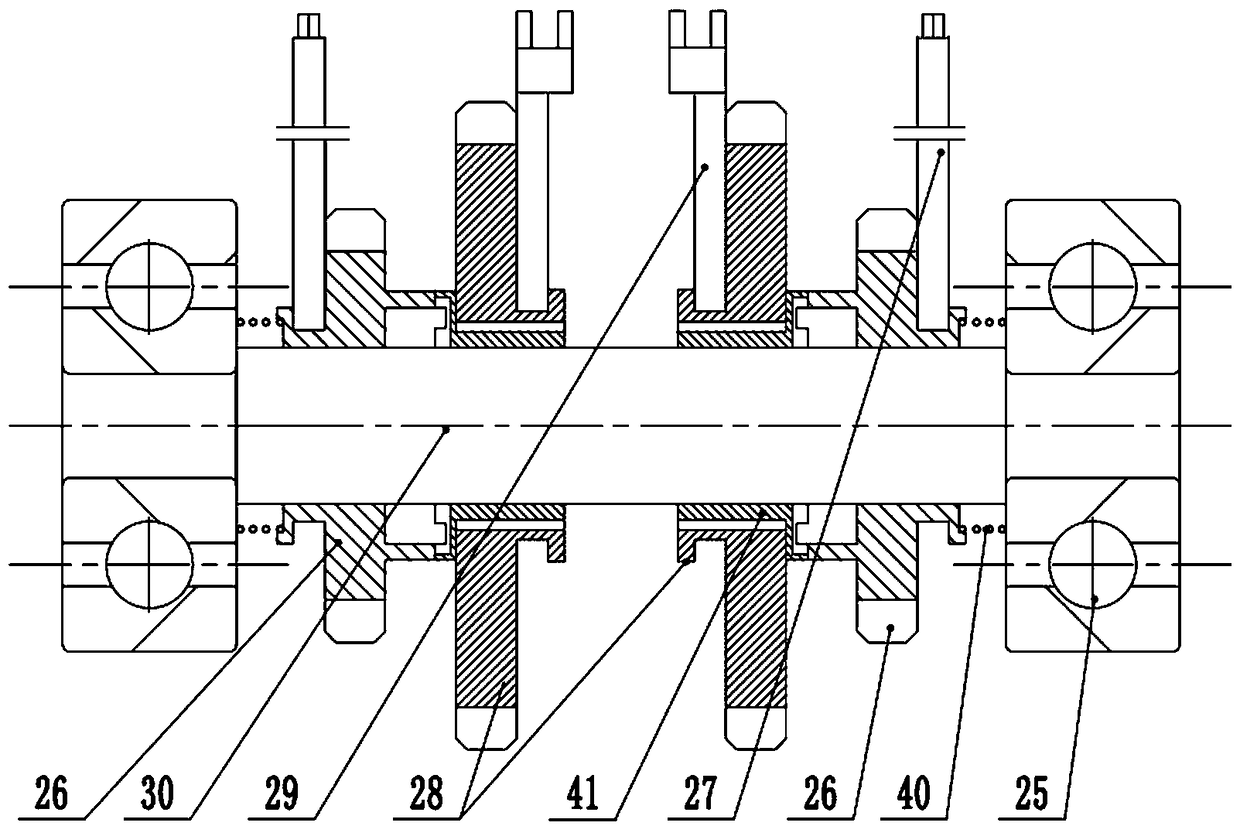

[0020] The gear transmission box that can complete the U-turn of the motor tricycle in situ includes a transmission box body 1 with an opening at the top of the transmission box body 1. The two sides of the transmission box body 1 are sequentially provided with a first shaft hole 17 and a second shaft hole from front to back. Shaft hole 18, third shaft hole 20 and drive shaft hole 21, the side between the second shaft hole 18 and the third shaft hole 20 is also provided with a reverse shaft hole 19; the front of the transmission case 1 is provided with a driving shaft Hole 2; the first shaft hole 17 is installed with the first shaft 4 through the first shaft bearing 3, and the driven bevel gear 5 and the transmission gear 6 are installed on the first shaft 4; the second shaft hole 18 is passed through the second shaft bearing 7. The second shaft 8 is installed, and the differential gear and the reverse transmission gear 15 are installed on the second shaft 8; the third shaft 30...

Embodiment 2

[0022]The gear transmission box that can complete the U-turn of the motor tricycle in situ includes a transmission box body 1 with an opening at the top of the transmission box body 1. The two sides of the transmission box body 1 are sequentially provided with a first shaft hole 17 and a second shaft hole from front to back. Shaft hole 18, third shaft hole 20 and drive shaft hole 21, the side between the second shaft hole 18 and the third shaft hole 20 is also provided with a reverse shaft hole 19; the front of the transmission case 1 is provided with a driving shaft Hole 2; the first shaft hole 17 is installed with the first shaft 4 through the first shaft bearing 3, and the driven bevel gear 5 and the transmission gear 6 are installed on the first shaft 4; the second shaft hole 18 is passed through the second shaft bearing 7. The second shaft 8 is installed, and the differential gear and the reverse transmission gear 15 are installed on the second shaft 8; the third shaft 30 ...

Embodiment 3

[0024] The gear transmission box that can complete the U-turn of the motor tricycle in situ includes a transmission box body 1 with an opening at the top of the transmission box body 1. The two sides of the transmission box body 1 are sequentially provided with a first shaft hole 17 and a second shaft hole from front to back. Shaft hole 18, third shaft hole 20 and drive shaft hole 21, the side between the second shaft hole 18 and the third shaft hole 20 is also provided with a reverse shaft hole 19; the front of the transmission case 1 is provided with a driving shaft Hole 2; the first shaft hole 17 is installed with the first shaft 4 through the first shaft bearing 3, and the driven bevel gear 5 and the transmission gear 6 are installed on the first shaft 4; the second shaft hole 18 is passed through the second shaft bearing 7 is equipped with a second shaft 8, and a differential gear and a reverse transmission gear 15 are installed on the second shaft 8; the differential gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com