Solid heat energy storage system with multiloop connectors

A thermal energy storage and multi-circuit technology, applied in heating systems, indirect heat exchangers, heating methods, etc., can solve problems such as insufficient heating capacity of the heating network, limited electricity consumption of thermal power plants, etc., to improve heat release adaptation performance, improve the effect of storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

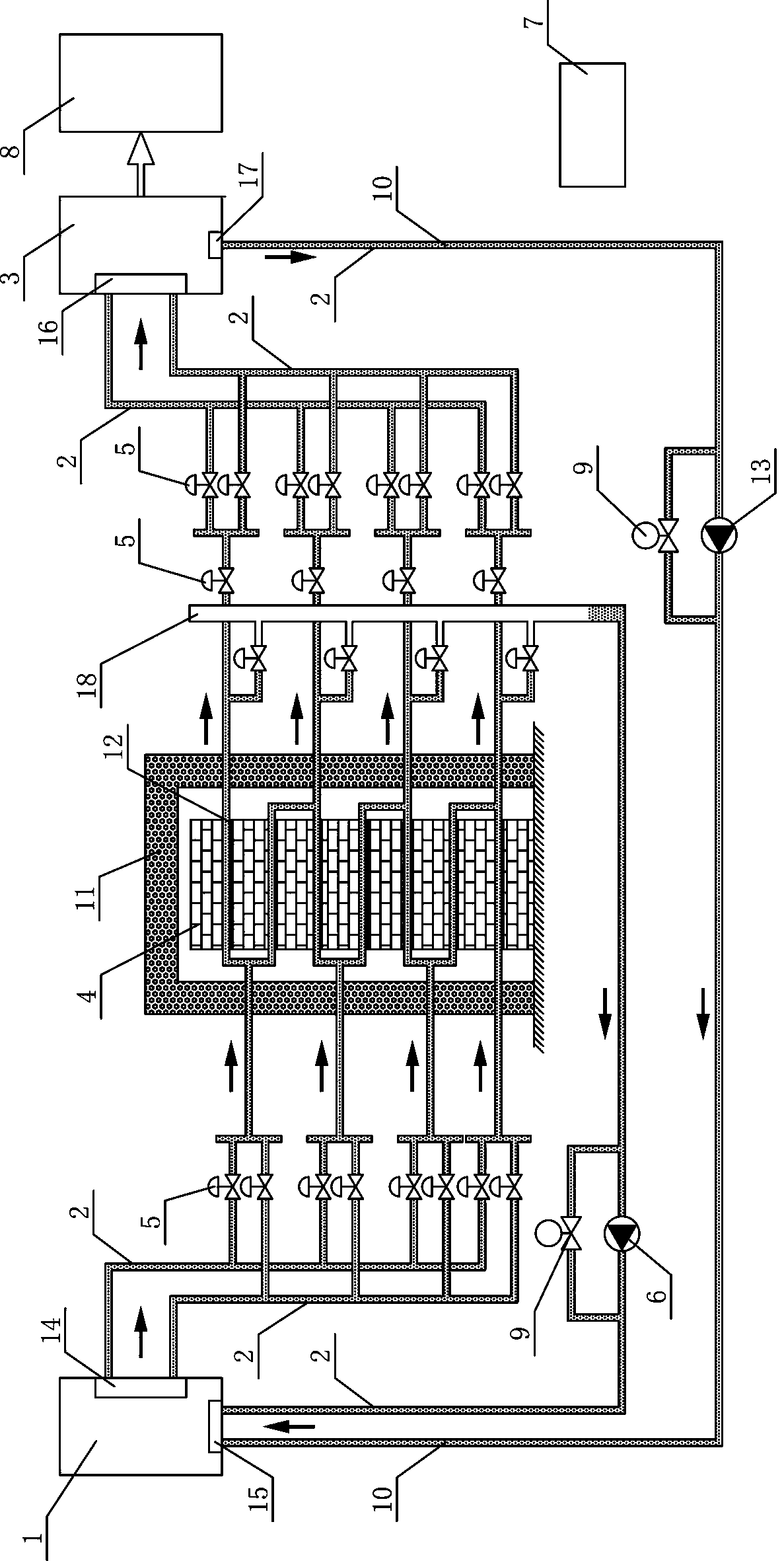

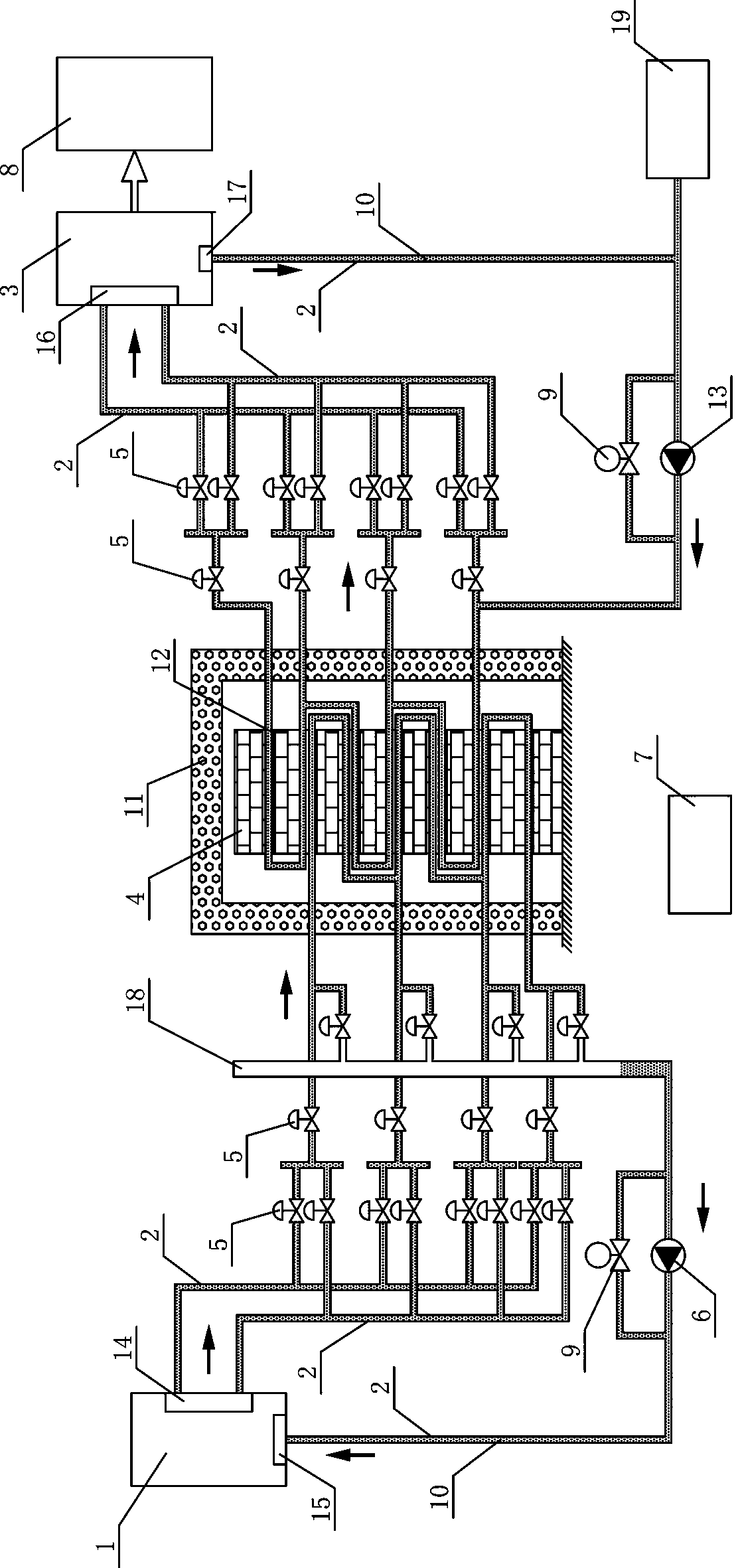

[0021] This example figure 1 As shown, it is a single-structure solid thermal energy storage system with a double-set heat storage loop and a double-set heat release loop interface; figure 2 As shown, it is a multi-group structure solid thermal energy storage system with double-set heat storage loops and double-set heat release loop interfaces. They include: multi-heat source system 1, pipeline 2, multi-heat exchange system 3, solid energy storage body 4, Valve group 5, variable frequency drive, control device 7, heat user 8, bypass valve 9, heat carrier 10, heat preservation layer 11, metal plate 12, heat release variable frequency drive 13, heat release output end 14, heat release return end 15, Heat exchange input end 16, heat exchange return end 17, dredging cavity 18, heat carrier constant pressure supplementary device 19.

[0022] Such as figure 1 The solid energy storage body 4 shown is a high temperature resistant building block body with an insulation layer 11 on t...

Embodiment 2

[0026] Such as figure 2 As shown, in addition to the heat carrier pipes in the solid energy storage body 4, the heat storage and heat release circuits adopt a multi-group structure in which parallel arrays are distributed and installed. figure 1 Heat carrier constant pressure supplementary device 19 is provided in more. The heat carrier constant pressure supplementary device 19, the heat exchange return end 17, and the exothermic frequency conversion drive 13 are connected by a pipeline 2. The purpose is to establish a stable heat release working condition through the heat carrier constant pressure supplementary device 19 arranged at the pump tail of the thermal variable frequency drive 13 . The working process is no longer described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com