Front-rear axle balance adjusting mechanism for locomotive

A technology of balance adjustment and balance mechanism, which is applied to agricultural machinery and implements, chassis and application of agricultural implements, etc., can solve problems such as low production efficiency, and achieve the effects of reasonable structure, improved adjustment and balance ability, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

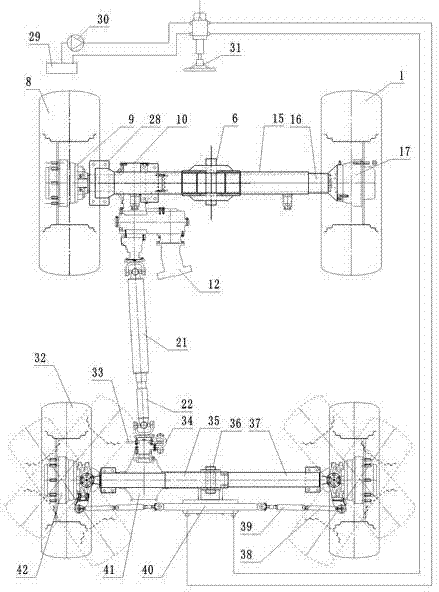

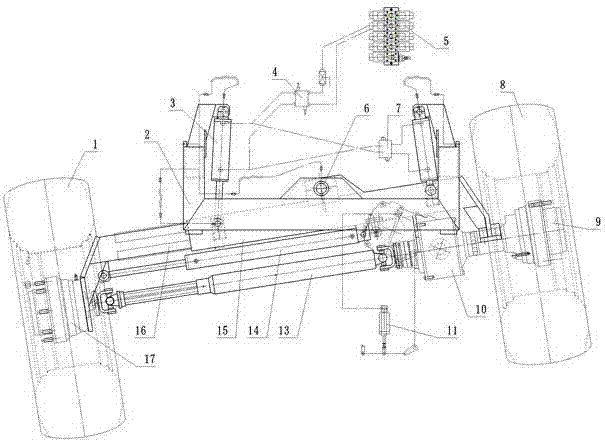

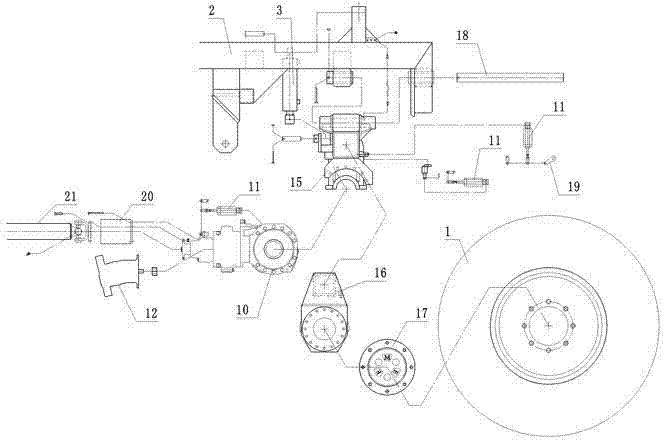

[0034] Example 1 : refer to figure 1 — Figure 13 , the present embodiment includes a chassis frame, a front axle, and a rear axle, and the front axle and the rear axle are respectively provided with a front axle horizontal horizontal balance mechanism and a rear axle balance adjustment mechanism;

[0035] The horizontal balance mechanism of the front axle includes a front bridge located between the two front wheels, the front bridge is mainly composed of an inner square tube 16 and an outer square tube 15, and the inner square tube 16 is set on the outer side In the pipe 15, the inner square pipe 16 and the outer square pipe 15 can be telescopically moved relative to each other. The front part 2 of the chassis frame is connected with the outer square pipe 15 of the front bridge. There is a front axle balance oil cylinder 3, the other end of the front axle balance oil cylinder 3 is connected with the outer square pipe 15, and a front axle shrinkage oil cylinder 14 is arrang...

Embodiment 2

[0041] Example 2 : refer to Figure 11 , one end of the rear axle movement adjustment oil cylinder 43 in the described rear axle balance adjustment mechanism is connected with the inner square pipe 37 of the rear axle frame, and the other end is connected with the slidable outer square pipe 35, the maximum distance that the slidable outer square pipe 35 can slide ≤half of the length of the square tube 37 in the rear axle frame. Figure 14 and Figure 15 It is a schematic diagram of the coordinated motion principle of the front and rear axles when the locomotive harvests and advances. As shown in the figure, the two front wheels in the front axle can adjust the wheelbase according to different planting modes. The rear axle balance adjustment mechanism of the present invention can be completed by cooperating with the front axle horizontal balance mechanism Adjust the balance of the overall frame to effectively improve the ability to adjust the balance of the rear axle and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com