Calibration method, device and terminal equipment of a detection device

A technology of a detection device and a calibration method, which is applied in the detection field and can solve problems such as low calibration accuracy and large position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059]In order to improve the accuracy of sampling needle calibration when calibrating the detection device, embodiments of the present application provide a calibration method, device and terminal equipment for the detection device.

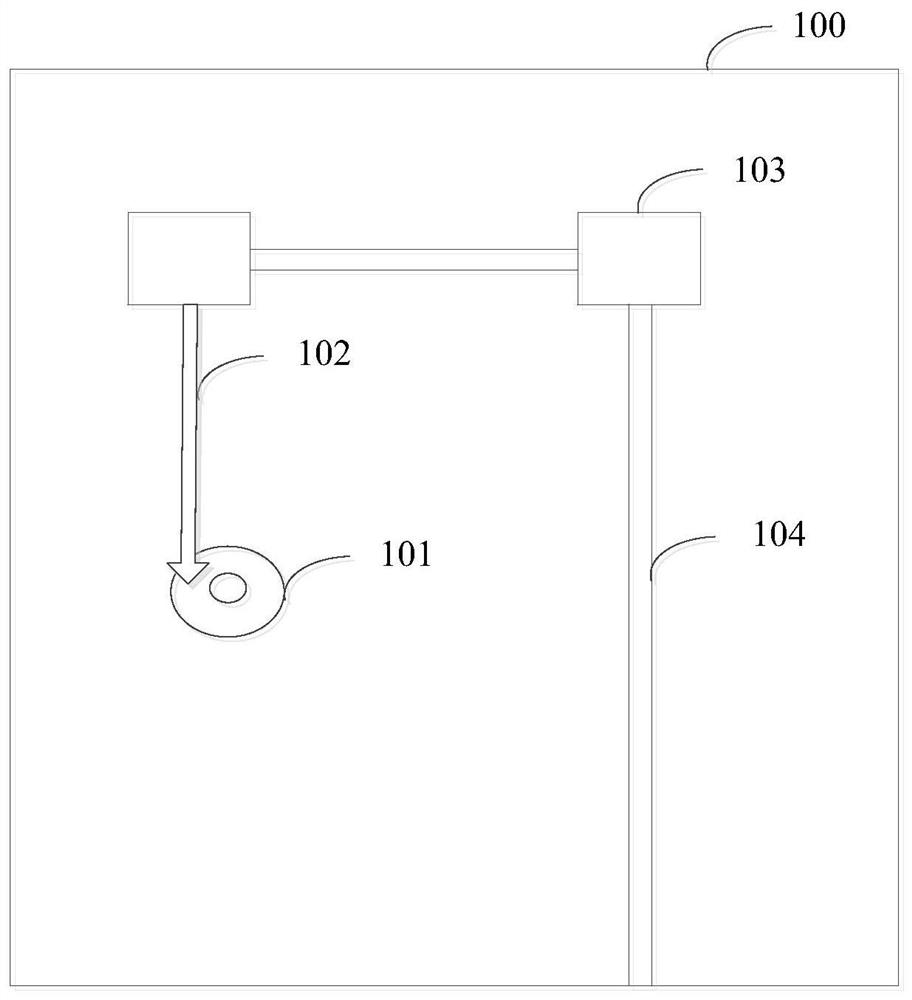

[0060] refer to figure 1 Shown is a schematic diagram of a detection device. The detection device 100 includes: a metal sheet 101 , an instrument needle 102 , a processor 103 and a sample arm 104 .

[0061] Wherein, the metal sheet 101 is made of metal, and there is a hole in the middle for inserting the instrument needle 102 into the cleaning pool, which is usually installed on the edge of the cleaning pool, and can also be arranged on other movement paths of the instrument needle. The metal sheet 101 is used to simulate the liquid level. In the embodiment of this application, only a metal sheet with a ring structure is used as the target conductive medium to simulate the liquid surface. The material and shape of the metal sheet 101 can be adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com