A cableless inclinometer with automatic lifting and automatic measurement

An automatic measurement and automatic lifting technology, applied in the direction of measuring inclination, measuring devices, instruments, etc., can solve the problems of failure to realize automatic intelligence, low work efficiency, high maintenance cost, etc., to avoid manual observation errors and reduce the cost of cables The effect of using and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

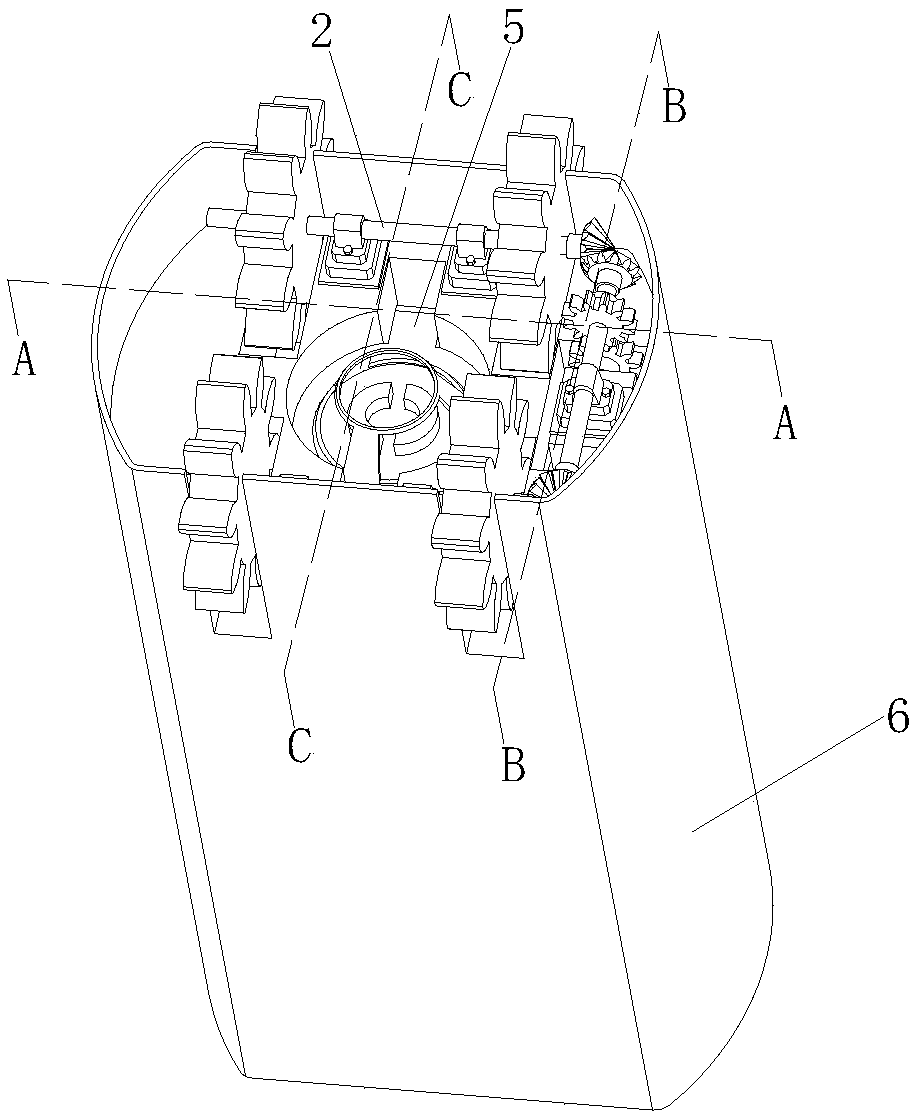

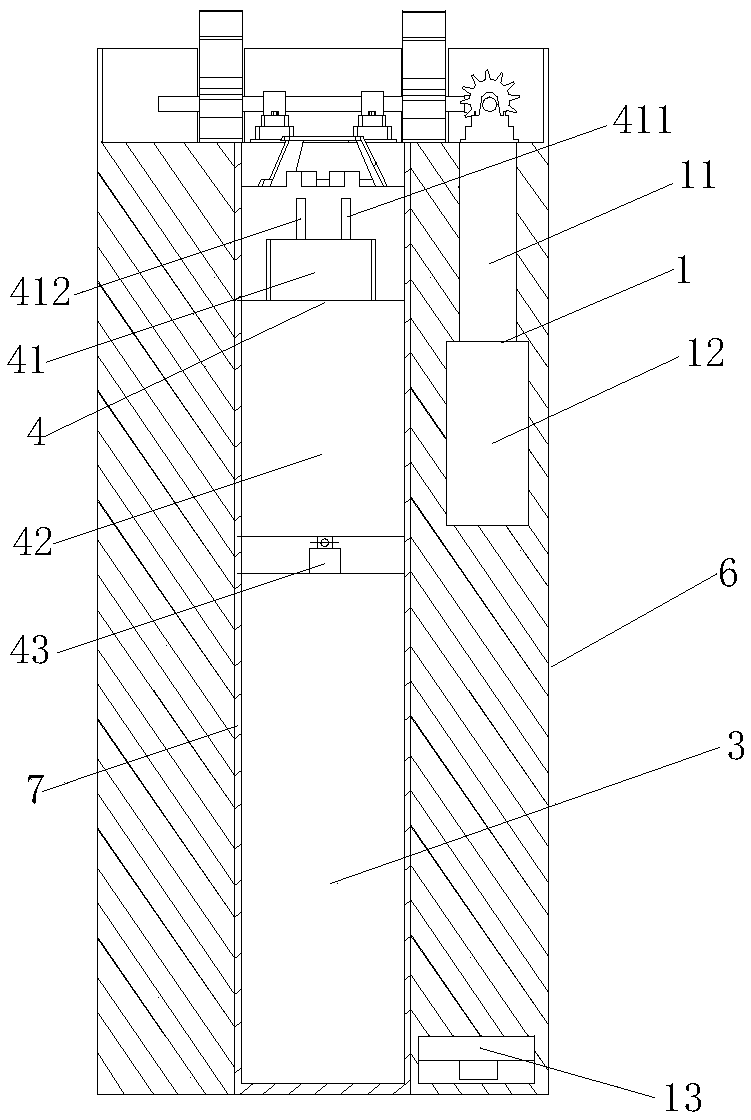

[0048] see Figure 1 to Figure 10 , a cableless inclinometer with automatic lifting and automatic measurement, including a power unit 1, a driving unit 2, a measuring unit 3, a signal transmission unit 4, a rescue unit 5, a casing 6, an inclinometer rod 7, and an inclinometer tube 8 .

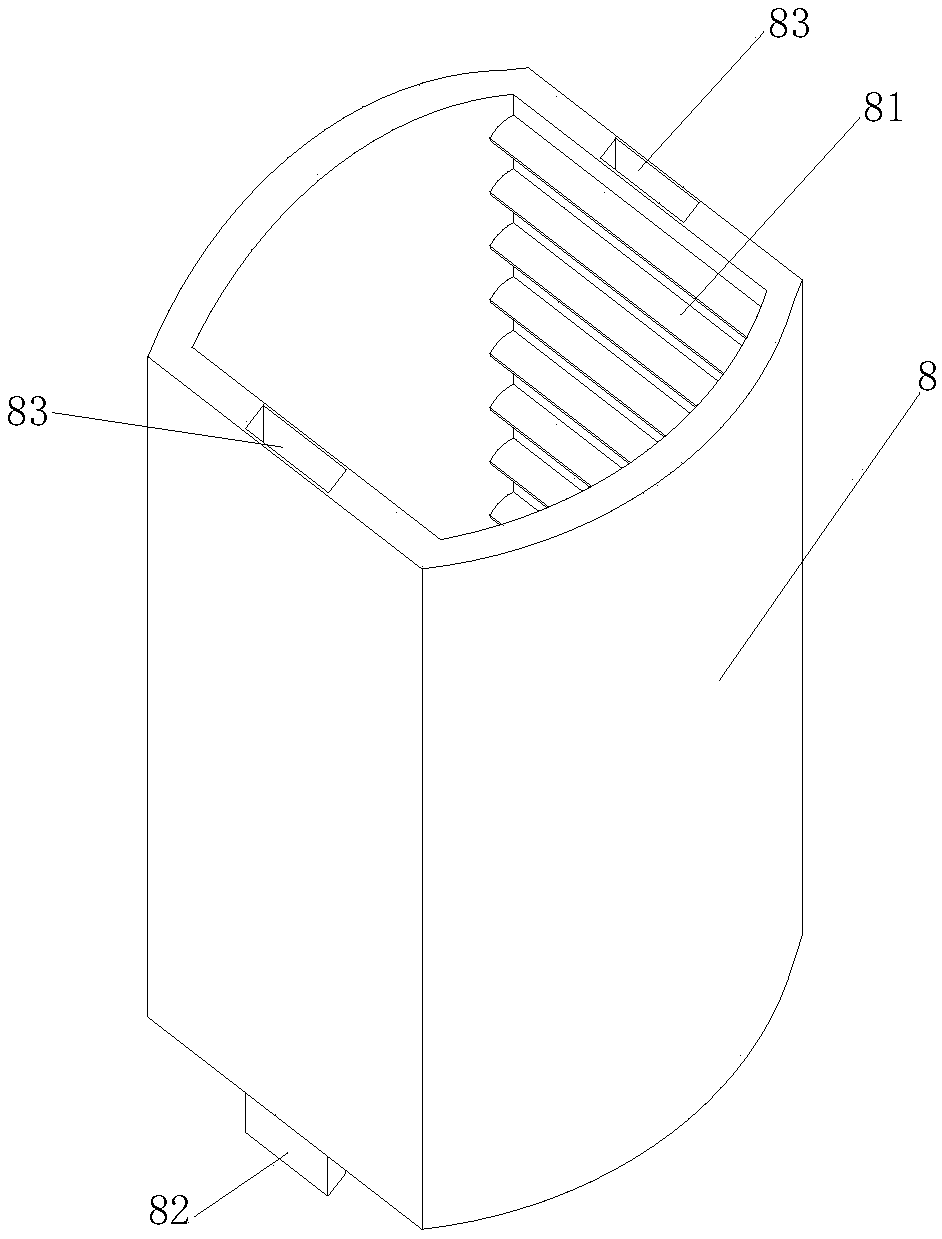

[0049] The inside of the inclinometer tube 8 has a rack 81 meshing with the transmission gear to realize the lifting of the present invention in the inclinometer tube 8 .

[0050] The lengths of the inclinometer tubes 8 are made into three specifications of 500mm, 1000mm, and 2000mm respectively, and several inclinometer tubes 8 are spliced through the inner positioning notch 82 and the outer positioning notch 83 according to the required length.

[0051] The power unit 1 and the drive unit 2 are connected and fixed in the casing 6, the measuring device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com