Jaw crusher tooth plate wear detection sensor and detection method

A technology for jaw crushers and detection sensors, which is applied to instruments, measuring devices, grain processing, etc., can solve problems such as insufficient accuracy, waste of manpower, and inability to feedback wear conditions in time, so as to avoid errors and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solutions and advantages of the present invention clearer, various implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

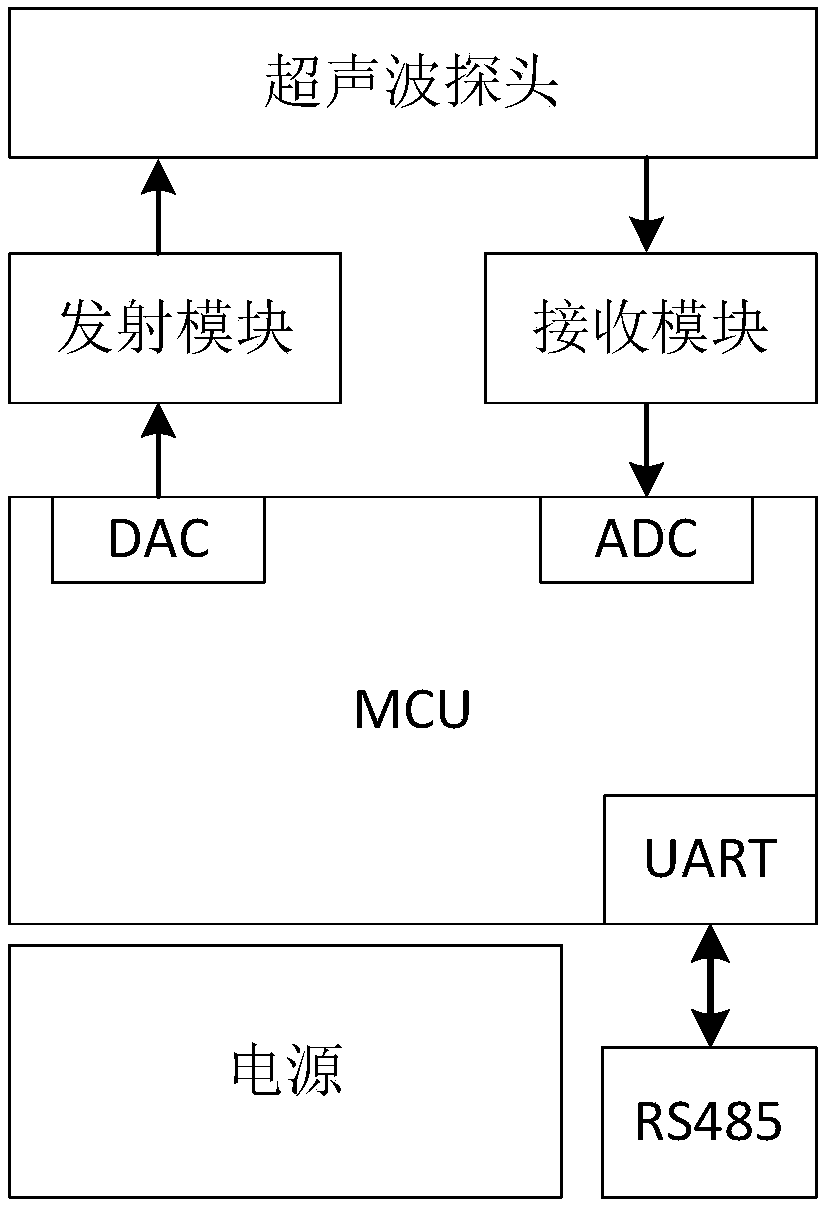

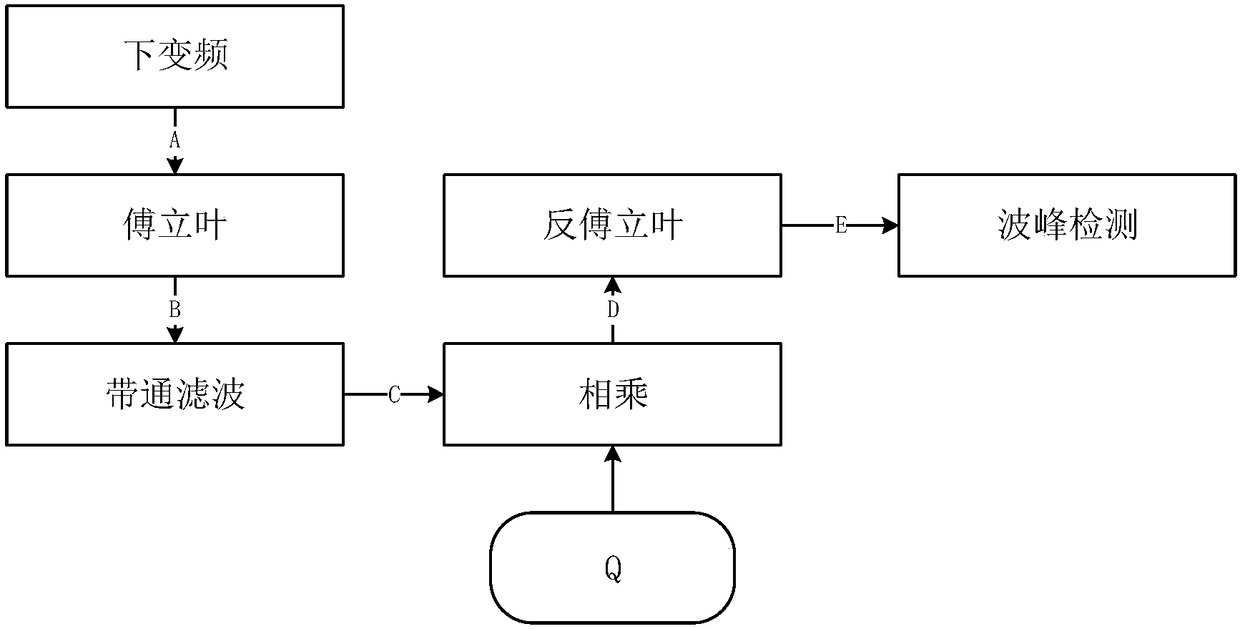

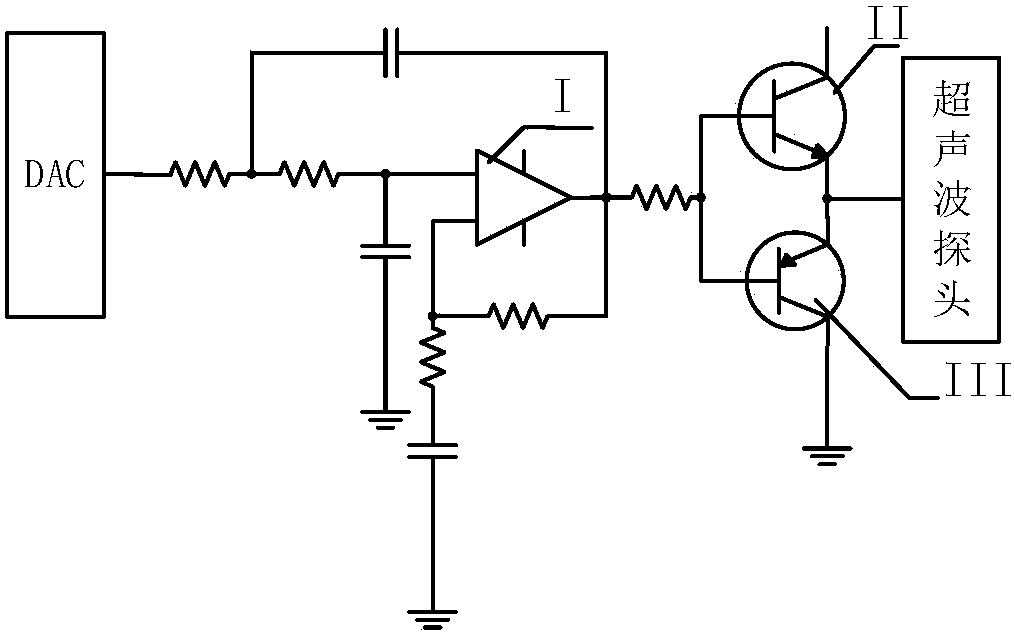

[0043] The present invention utilizes the characteristics of ultrasonic transmission to reflect at the edge of different material interfaces to measure the thickness of the tooth plate of the jaw crusher so as to calculate the wear amount of the tooth plate. First, a group of coded ultrasonic waves are transmitted from the ultrasonic probe to one side of the tooth plate. When the ultrasonic waves pass through the edge of the interface between the other side of the tooth plate and the air, a strong reflected wave will be generated, which will penetrate the tooth plate and return to the ultrasonic probe. The difference t between the ultrasonic sending time and the ultrasonic receiving time, according to the formula s=s i -v*t / 2 can calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com